Floating-type air pressure angle-fixed double-clamp vise structure

A floating vise technology, applied in the vise field, can solve the problems of stress concentration, reduced service life, slow processing speed, etc., and achieve the best processing precision, ensure the service life, and the best clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

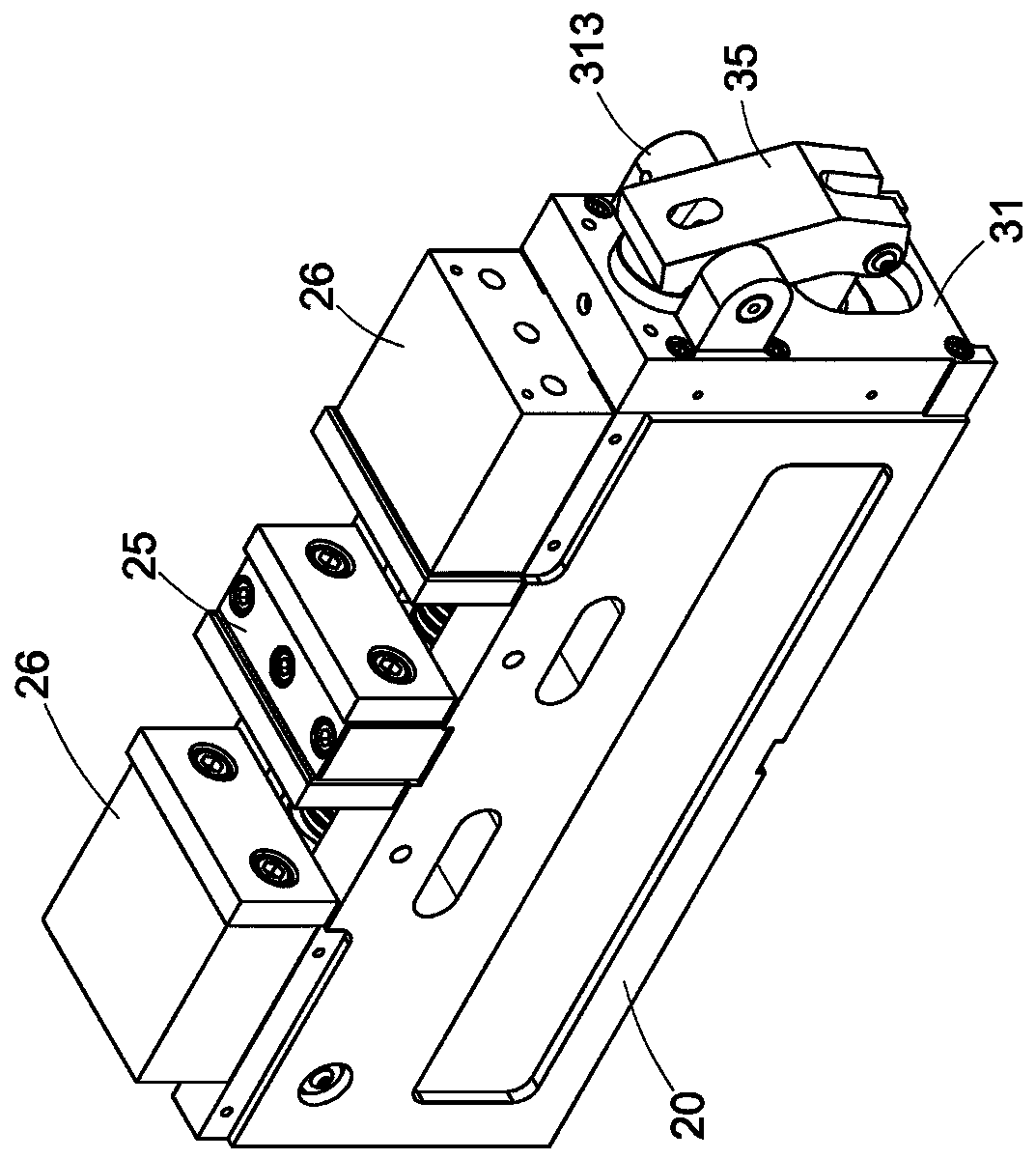

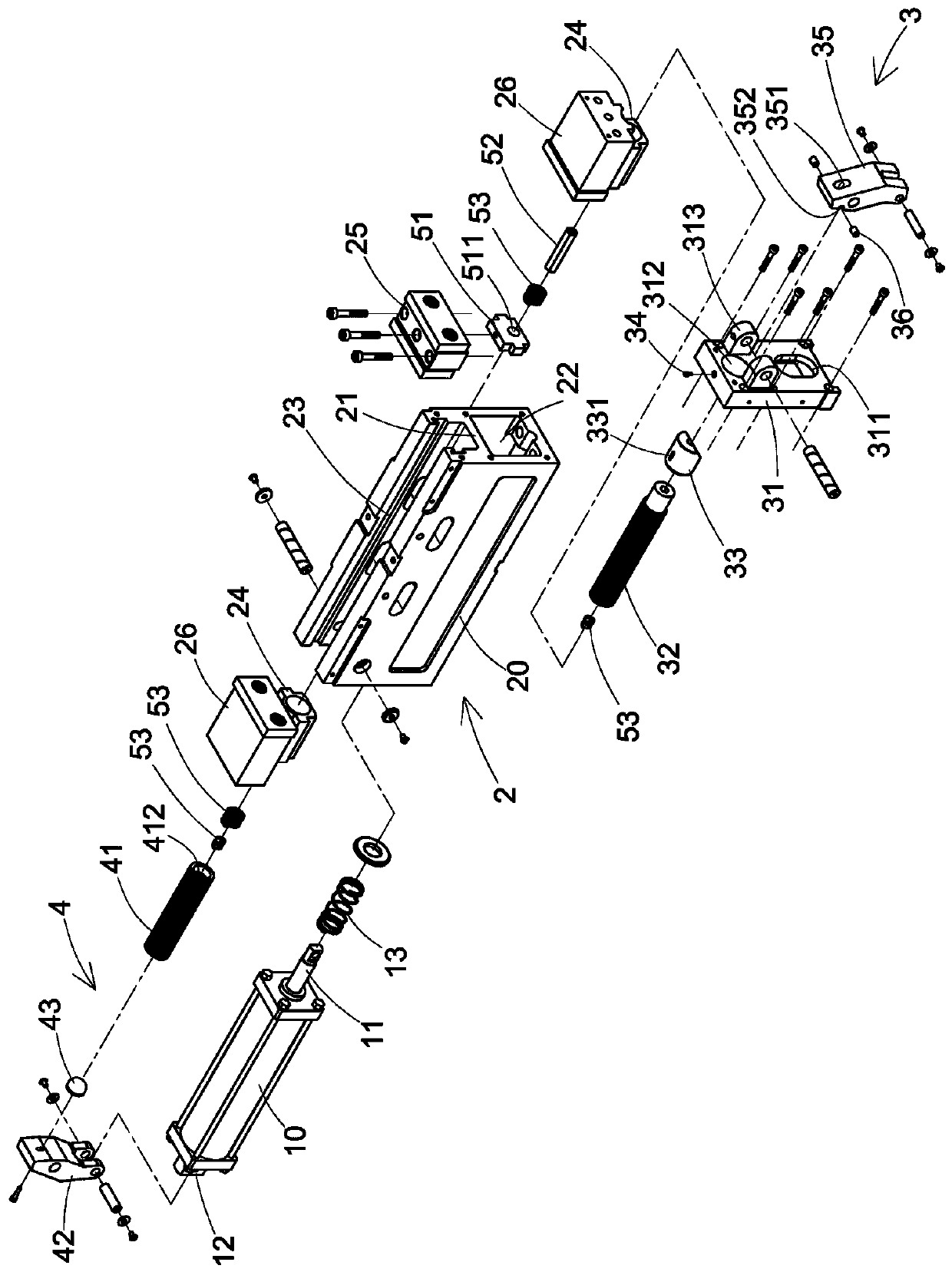

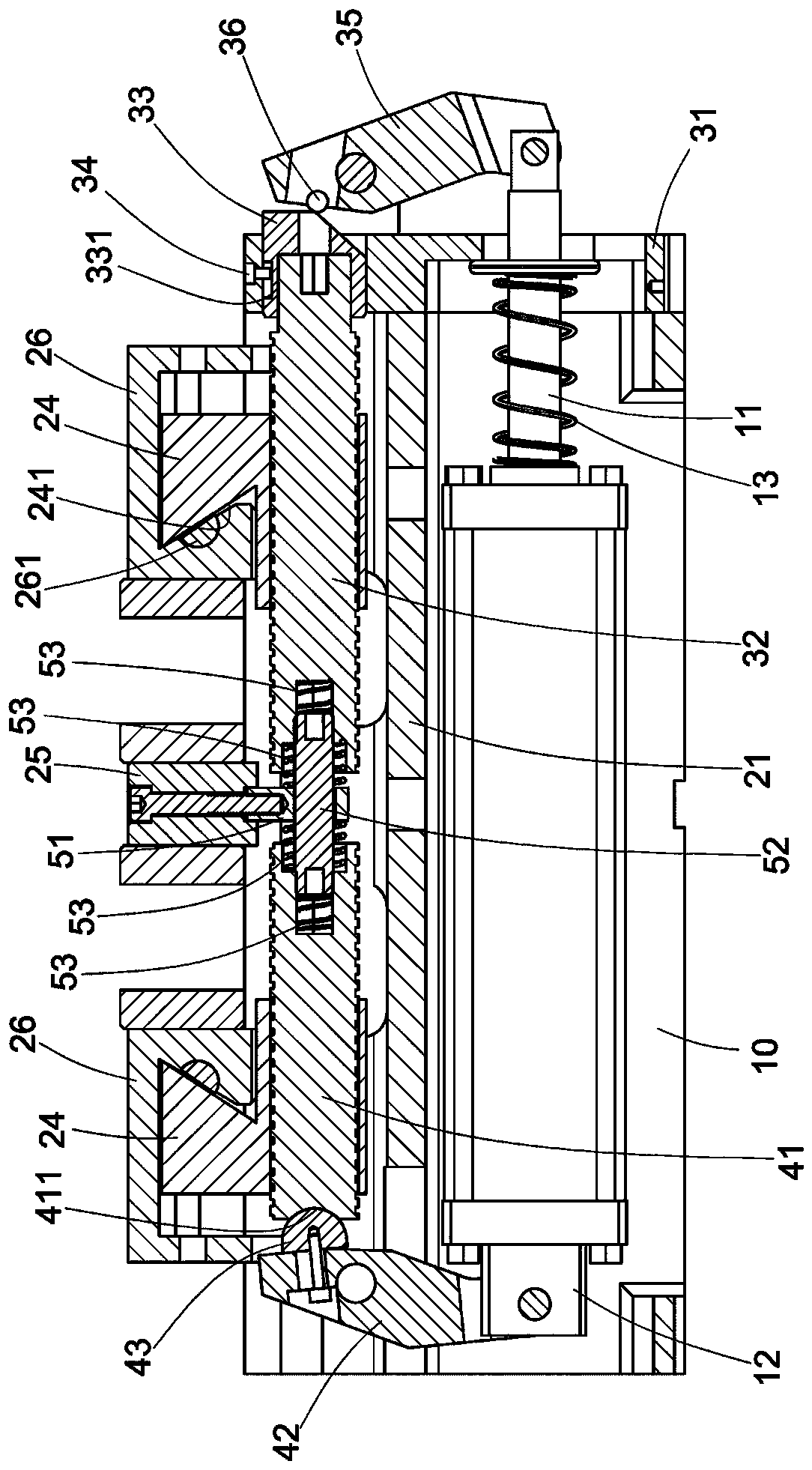

[0048] First, please refer to Figure 1 to Figure 5 As shown, the present invention is a floating air pressure angle fixed double clamp vise structure, which includes:

[0049] A pressure cylinder 10, the pressure cylinder 10 has a first push rod 11 and a second push rod 12;

[0050] A vise unit 2, the vise unit 2 has a body 20, a partition wall 21 is arranged laterally near the middle of the body 20, and the bottom surface of the partition wall 21 has an accommodating space 22 for the pressure cylinder 10 , and the relative setting position of the inner edge surface of the top surface of the partition wall 21 is provided with a guide rail 23 respectively. A fixed jaw 25 is fixed at the central position of the top surface of the body 20, and a movable jaw 26 with a pressing bar 261 is respectively installed on the two sides of the top surface of the main body 20 located at the fixed jaw 25, so that each pressing bar 261 is respectively pressed by the pressing inclined surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com