Universal automobile front end anti-collision beam

An anti-collision beam, general-purpose technology, applied in bumpers and other directions, can solve problems such as poor versatility, and achieve the effects of simple design, good use effect, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

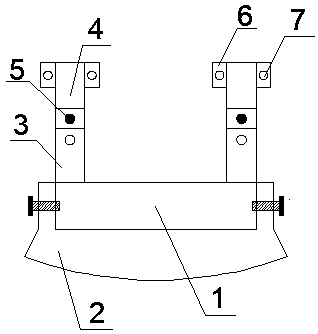

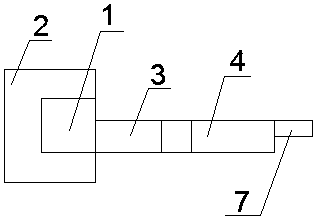

[0011] Such as figure 1 , 2 It is a structural schematic diagram of the present invention, a general-purpose automobile front-end anti-collision beam, including a main beam 1 and a rubber buffer layer 2, the rubber buffer layer 2 surrounds the entire front end of the main beam 1, and the rubber buffer layer 2 is fixed on the main beam 1 by bolts On both sides, the square tube one 3 is welded symmetrically on both sides of the rear end of the main beam 1, and the square tube two 4 is sleeved in the square tube one 3, and the square tube one 3 and the square tube two 4 are all provided with adjustment holes 5, and the adjustment holes 5 place bolts to connect the square tube one 3 and the square tube two 4, weld the fixed steel sheet 6 on both sides of the end of the square tube two 4, and the fixed steel sheet 6 is provided with a fixing hole 7.

[0012] This device is connected by two square tubes, the first square tube 3 is fixed, the second square tube 4 can be adjusted, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com