Cross shaft type electric transmission track-laying vehicle differential traveling device driven by two motors

A dual-motor drive and traveling device technology, applied in the transmission device, vehicle components, non-deflectable wheel steering, etc., can solve the problems of complex structure, high maintenance cost and high cost of hydraulic system, and achieve simple control, simple structure, and layout reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

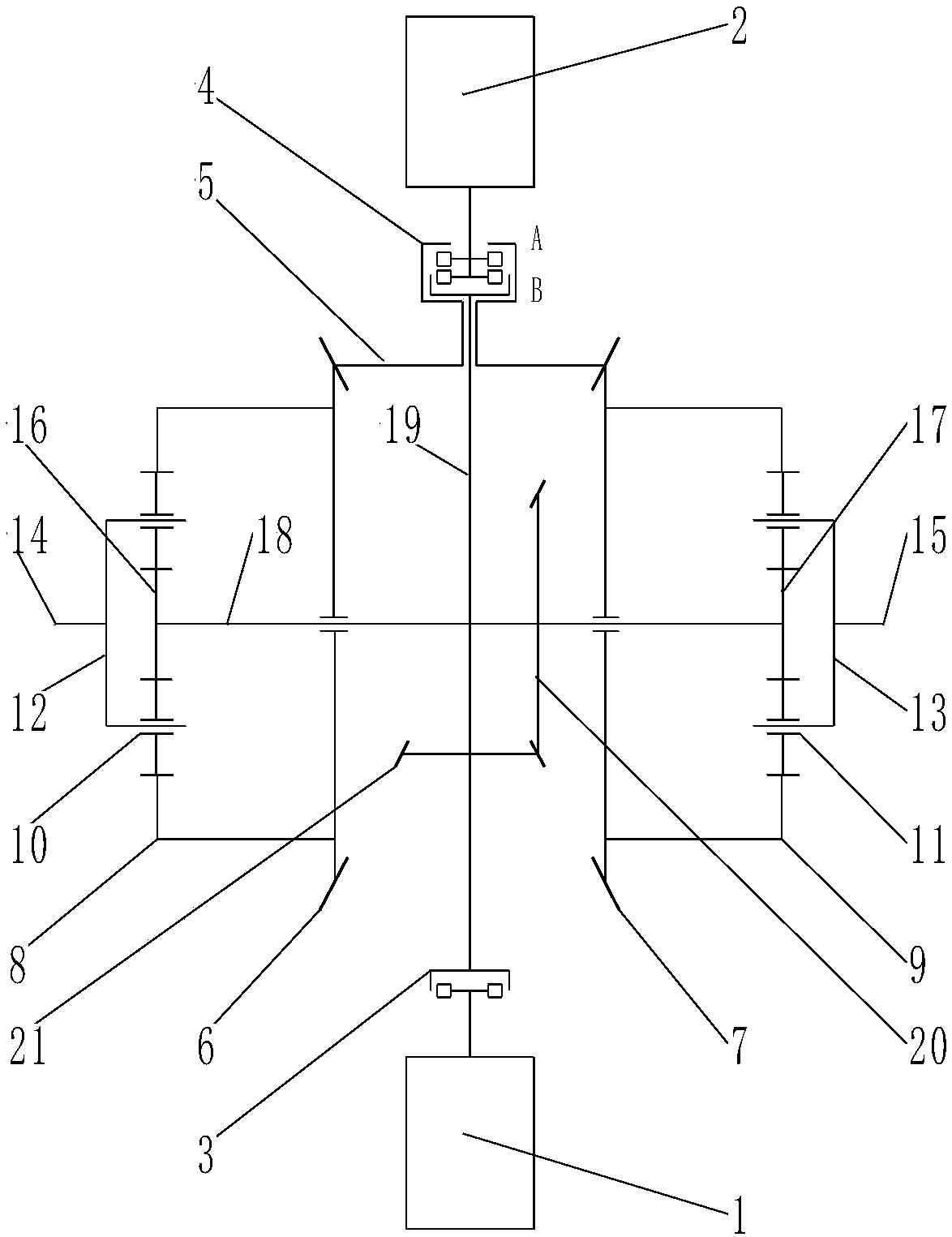

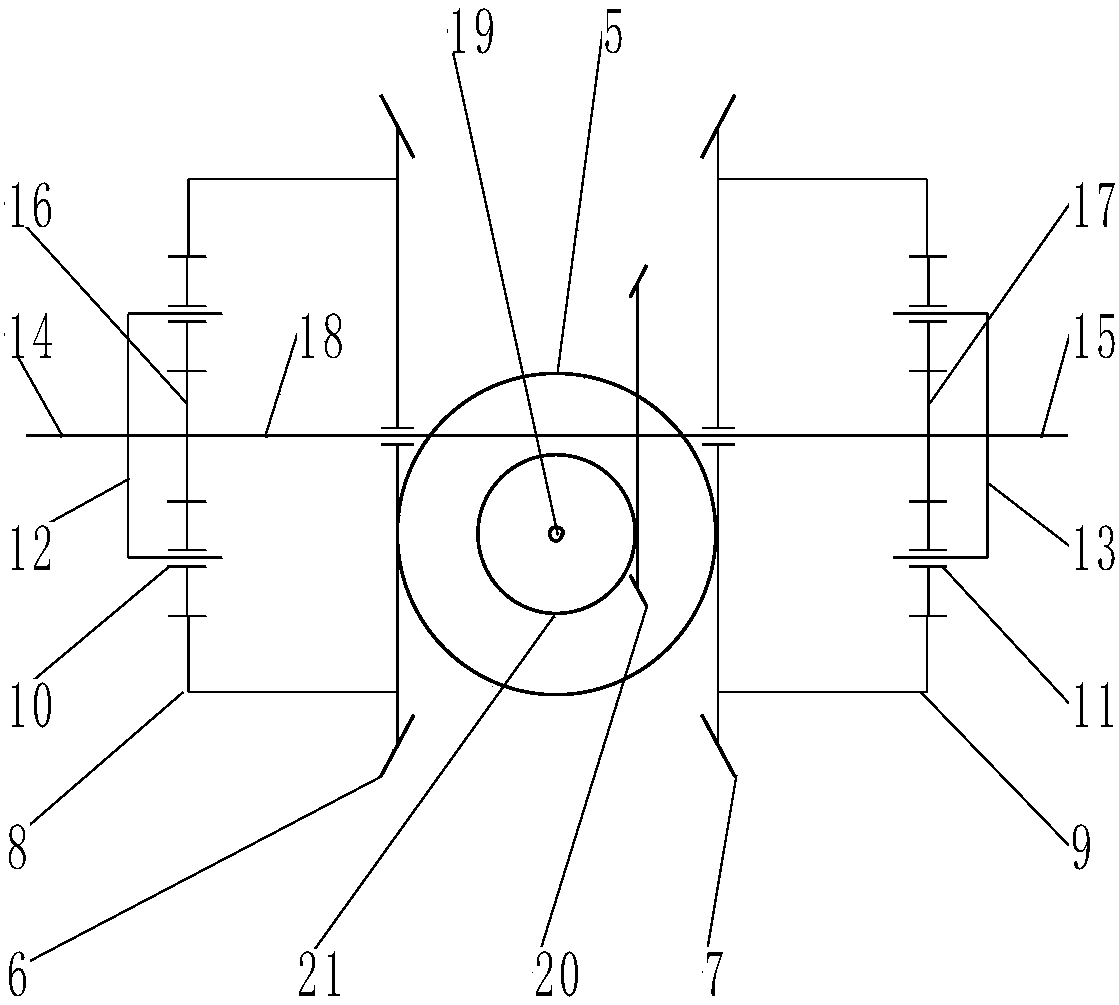

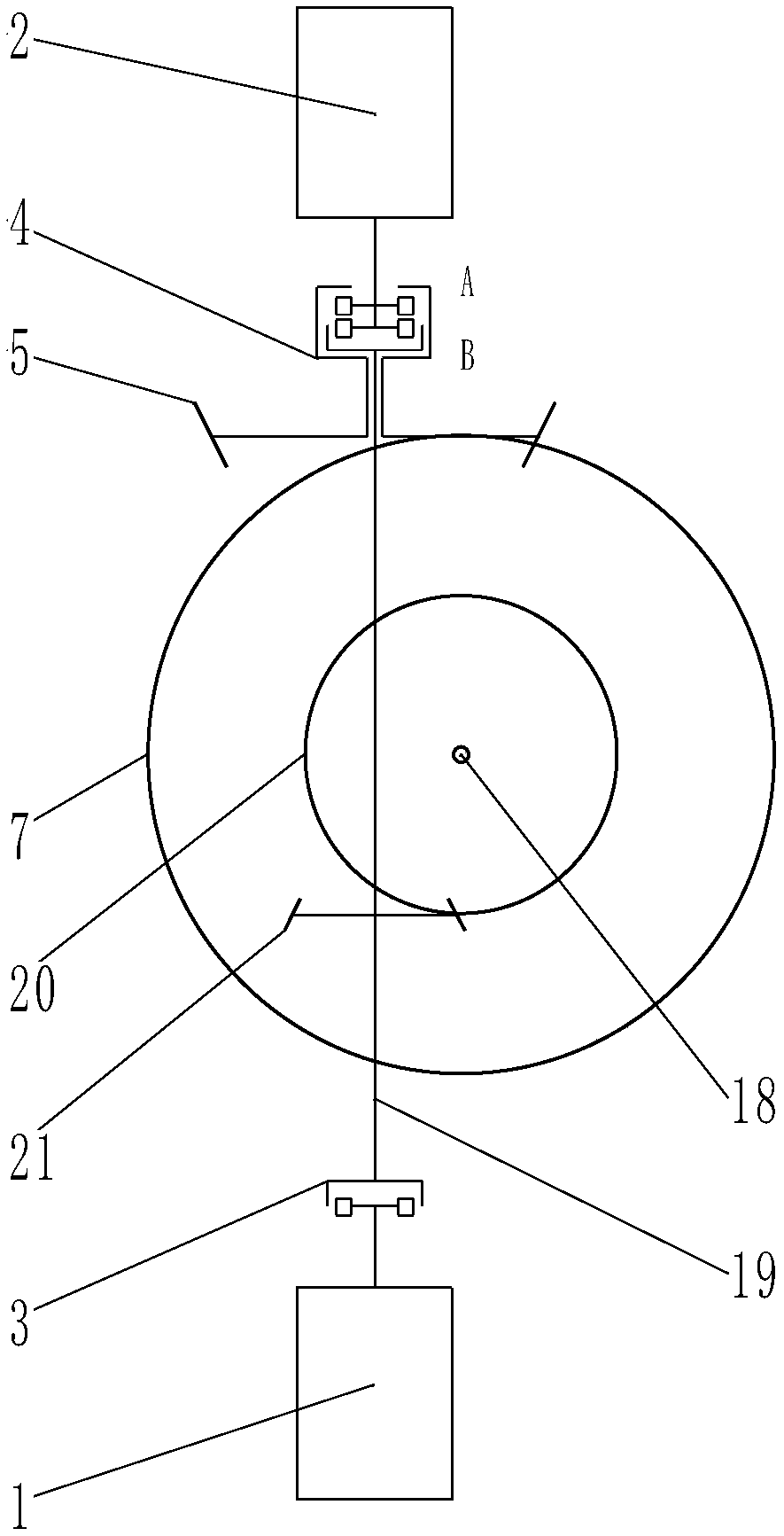

[0021] The running states of tracked vehicles are divided into straight line running, turning in situ and turning. In the present invention, according to the control to the clutch connection state, the above three running states of tracked vehicles can be realized. Different driving speeds and turning radii of tracked vehicles can be realized through the control.

[0022] Referring to Table 1, O is for clutch connection, and X is for clutch disconnection.

[0023] When the one-way clutch 3 was connected, and the two-way clutch 4A end and the B end were all in the disconnected state, the driving bevel gear 5 must be fixed, and now the tracked vehicle was a straight-line running state driven by a single motor (drive motor 1). The power is generated by the drive motor 1 and transmitted to the sun gear I16 and sun gear II17 through the main transmission device. At this time, the ring gear I8 and the ring gear II9 are in a fixed state, so the power passes through the planetary carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com