Quick connecting structure for prefabricated pier and slab

A quick connection and prefabricated concrete technology, which is applied to pavements, roads, and pavement details paved with prefabricated blocks, can solve the problems of many temporary facilities, difficult construction, and many damaged steel bars, and achieve the elimination of many temporary facilities, The effect of reducing the workload on site and reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] In order to meet the development requirements of standardization, systematization, modularization, and assembly in the industrial construction of green highways, a prefabricated pier and slab quick connection structure is designed.

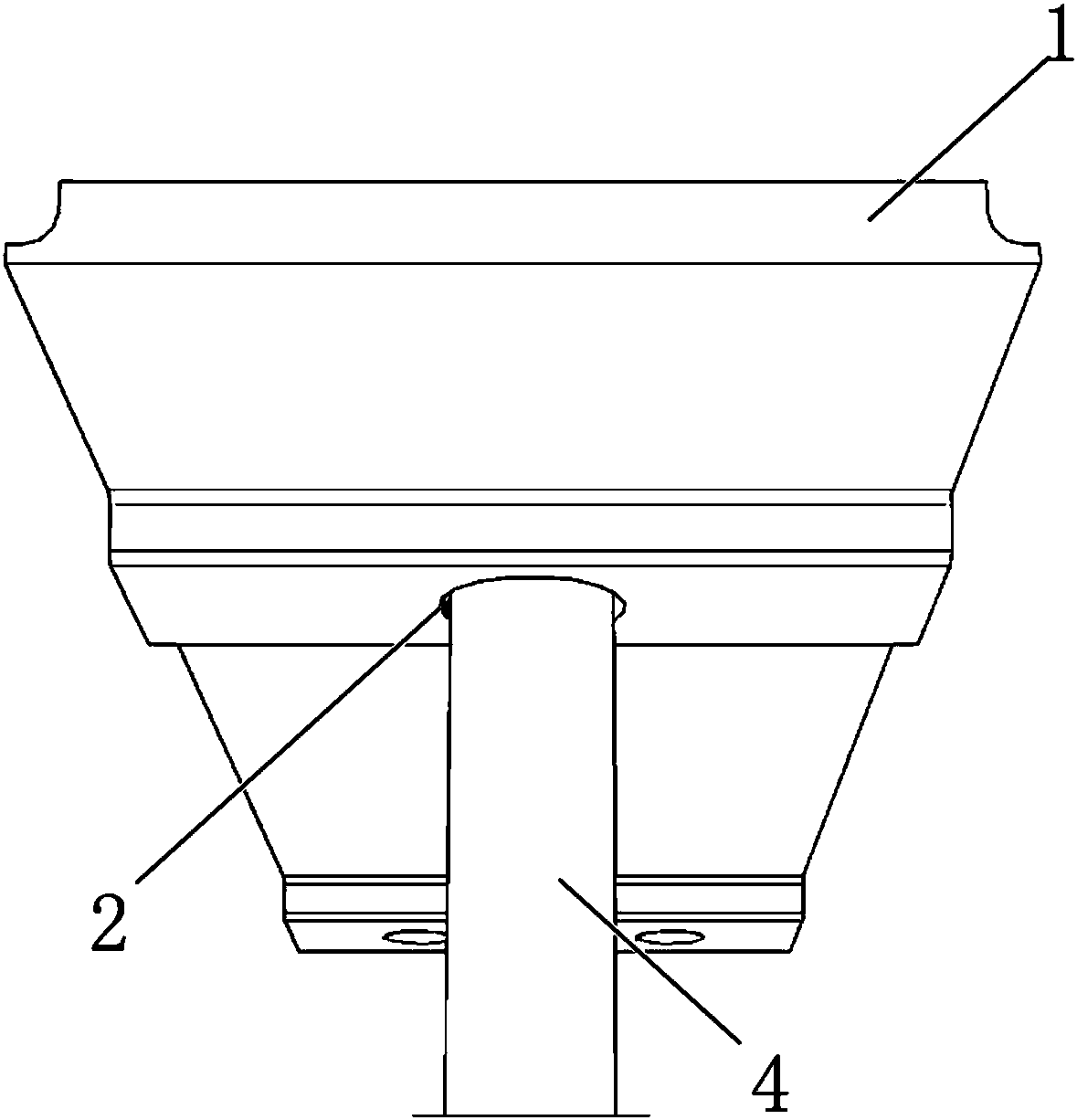

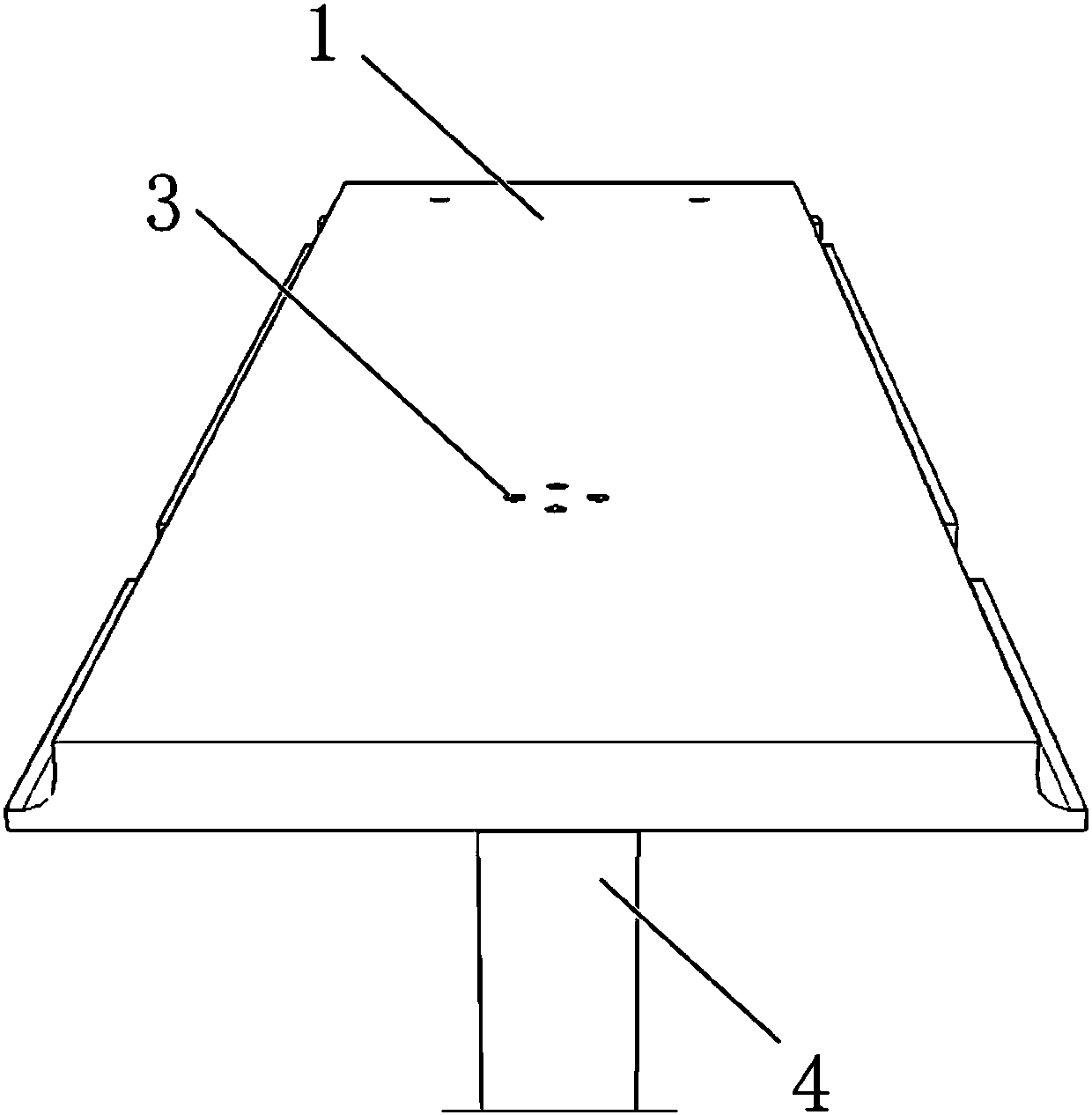

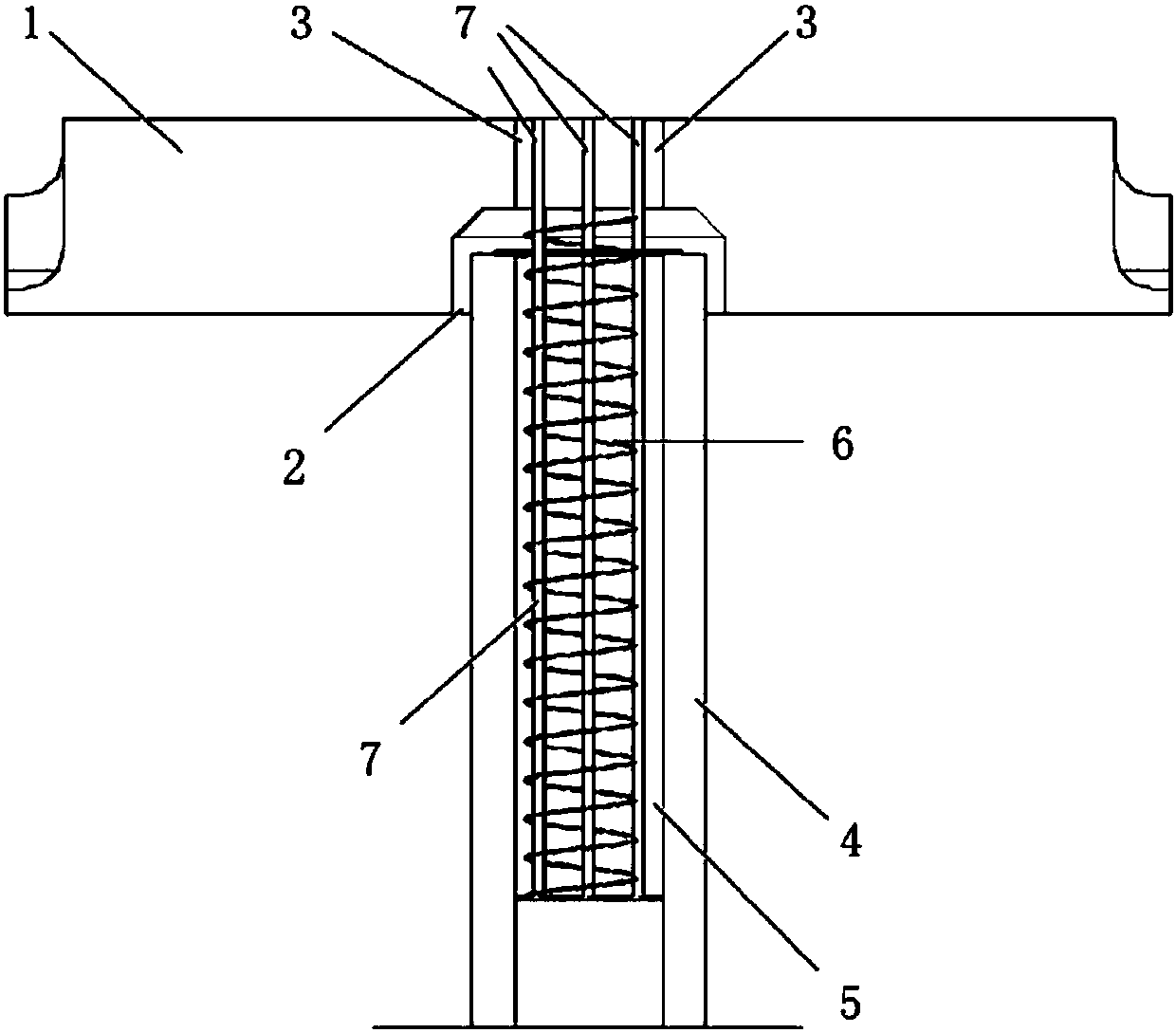

[0024] A prefabricated pier and plate quick connection structure, such as Figure 1-4 As shown, it includes a precast concrete beam slab 1 and a precast concrete pier 4. The bottom of the precast concrete beam slab 1 is provided with an embedding groove 2, and the top of the precast concrete beam slab 1 is provided with a vertical communication hole 3. The communication hole 3 and the The embedding grooves 2 are connected, and the precast concrete pier 4 is provided with a pier top cavity 5, and a vertical anchoring reinforcement 7 is arranged in the pier top cavity 5, and an anchoring reinforcement skeleton 6 is arranged around the anchoring reinforcement 7, and the precast concrete pier 2 When assembling, the embedding groove 2 is embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com