Whole ascending method of dumping machine

A technology for excavating and lifting sections, which is used in earth-moving drilling, earth-moving machines/shovels, movable tracks, etc., can solve the problems of long construction period, inability to meet actual production needs, and large engineering volume, etc. To achieve the effect of reducing the amount of earthwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

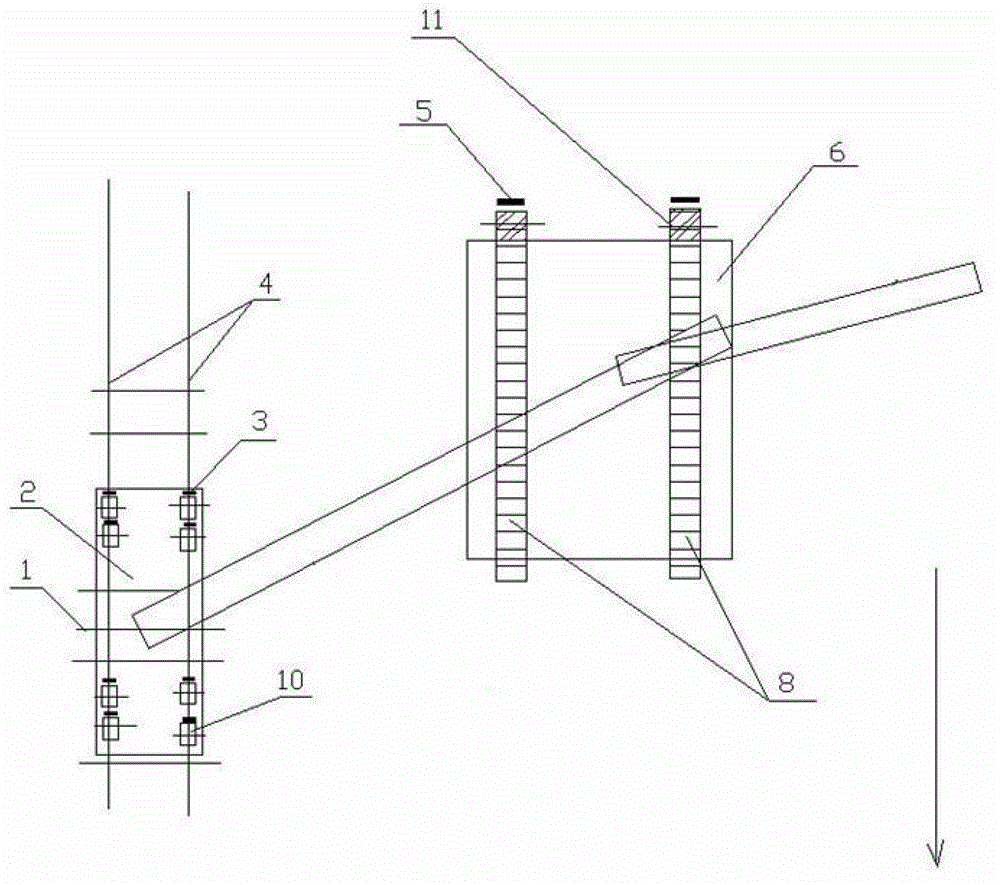

Image

Examples

Embodiment Construction

[0022] The overall lifting method of the bulldozer provided by the embodiment of the present invention includes conducting a feasibility test before the whole bulldozer lift, so as to determine the climbing ability of the bulldozer and the unloading truck, and then determine the walking speed of the bulldozer based on this. The road construction plan and the determination of the construction plan for the unloading vehicle to walk the railway, and finally the construction plan for the lifting section of the earth dumper.

[0023] A. to conduct a feasibility test

[0024] The test environment is determined according to the mine conditions: the iron ore dump site of Shougang Waterworks has a temperature of -25°C to +40°C, an annual average rainfall of 756mm, a daily maximum of 283mm, a maximum wind speed of 16.7m / s, and a maximum snowfall of 16cm. The rock composition is mixed with marble, gneiss, feldspar and quartz stone, the original rock density is 2.71t / m3, the soft rock den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com