A test device and test method for anti-corrosion performance

A test method and test device technology, which are applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of lack of molten salt freezing wall protection effect, etc., to prevent environmental pollution and damage to operators, Ensures testing, avoids the effect of high temperature operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

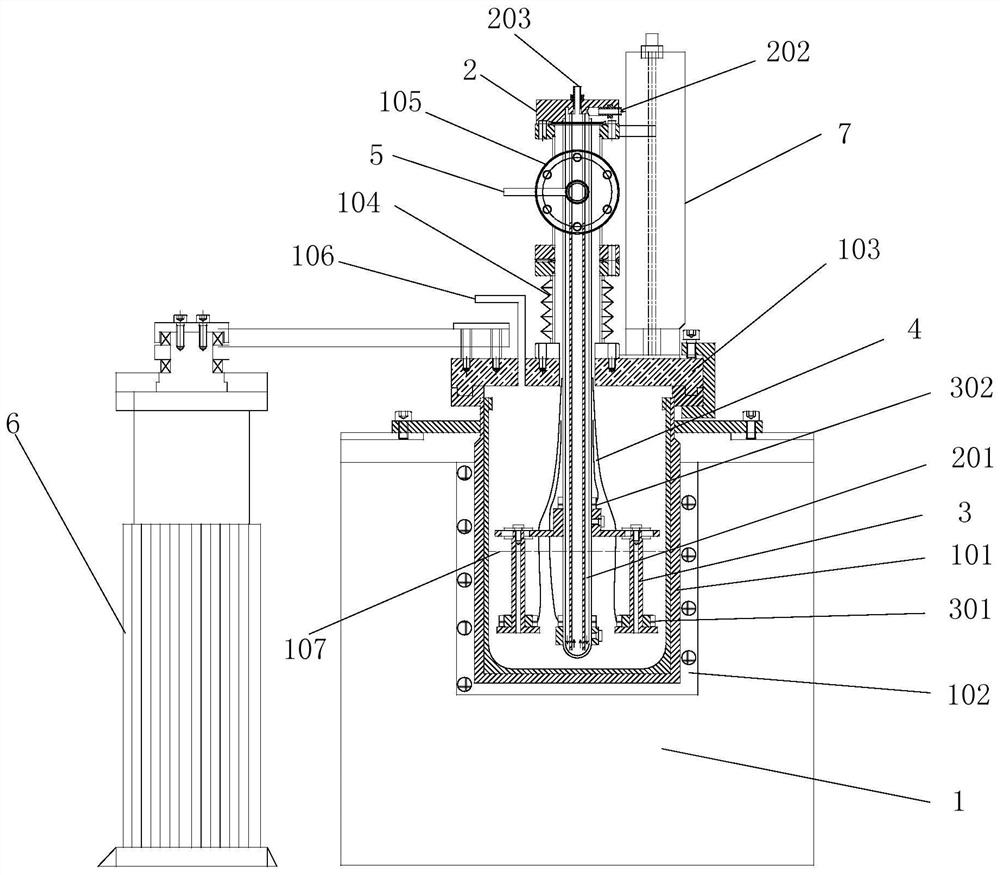

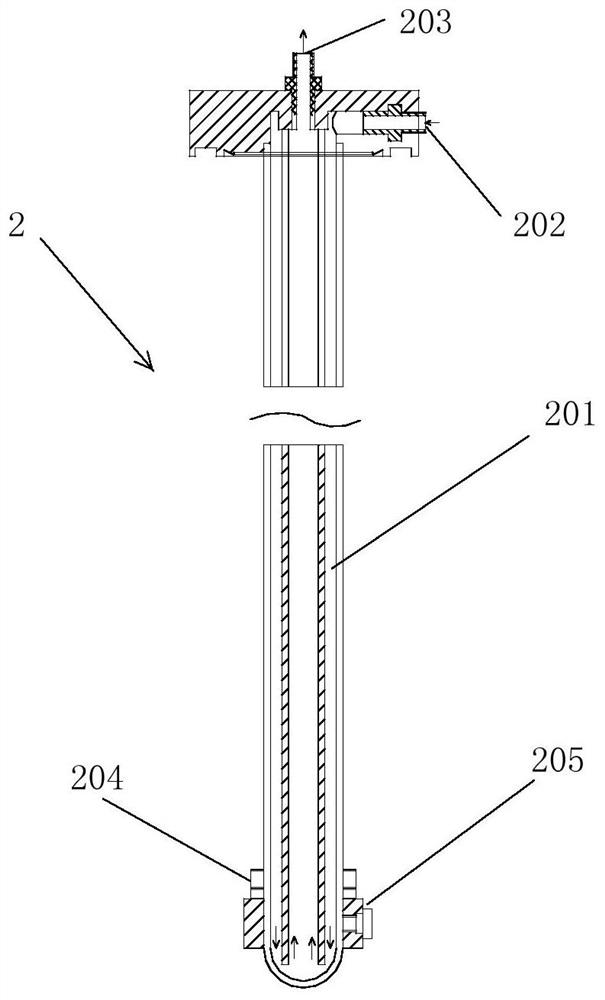

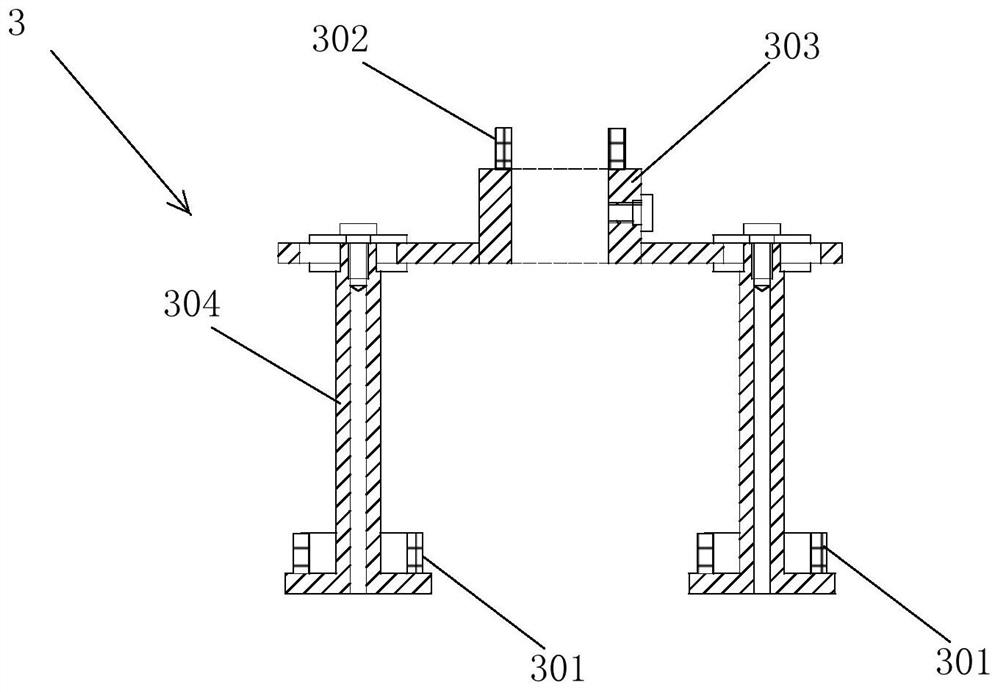

[0070] Such as Figure 1 ~ 7 As shown, the present embodiment provides a test device including a heating tank 1, a cooling rod 2, a four-way connecting head 105, a telescopic bellows 104, a bottom ventilator 5, a thermocouple A bundle 4, a sample holder 3 and a first sample fixing ring 205, the heater 1 comprising an kettle body 101 and a clavocker 103, and an inner surface of the kettle body 101 also has a heater. 102. The cooling rod 2 is perpendicular to the center of the lane 103 and rejuble into the kettle body 101, which divides the cooling rod 2 into an upper and lower segments, said The top of the cooling rod 2 is also provided with a cooling rod rising drop 7 for overall up and lower the cooling rod 2 and its respective members; there is an air outlet 106 on the lace 103. And an kettle lift 6, the capping lifter 6 is used to perform overall up and down of the glue cover 103 and their respective members.

[0071] The four-way connecting head 105 has four channels, the upper...

Embodiment 2

[0082] In this example, a specific embodiment of the anti-corrosion performance test is performed using the test apparatus of Example 1. The molten salt used is a FLINAK melt salt, and the test method includes the following steps:

[0083] S1, open the kettle lifter 6 up to the upper lid 103, and 4 kg 46.5-11.5-42 mol% LIF-NAF-KF solid salt (melting point 454 ° C) is loaded into the heater 1;

[0084] S2, mount the telescopic bellows 104, the four-way connecting head 105, and the cooling rod 2 are mounted on the kettle cover 103, and the cooling rod rises 7 rises to the highest bit, the sample bracket 3 and test samples are installed, and the test sample material is SS316L. Stainless steel, adjust the temperature of the thermocouple to each sample surface;

[0085] S3, the lava lifter 6 is lowered and the kettle body 101 is mounted, and the heater 102 is opened to 550 ° C and heat the solid salt, and the liquid height is about 100 mm;

[0086] S4, the cooling rod floor down reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com