Domestic appliance having a cleaning apparatus for heat exchangers

A technology for heat exchangers and household appliances, applied to washing devices, household clothes dryers, applications, etc., can solve the problems of reducing the efficiency of the first heat exchanger 4, and achieve the effect of increasing the effective distance

- Summary

- Abstract

- Description

- Claims

- Application Information

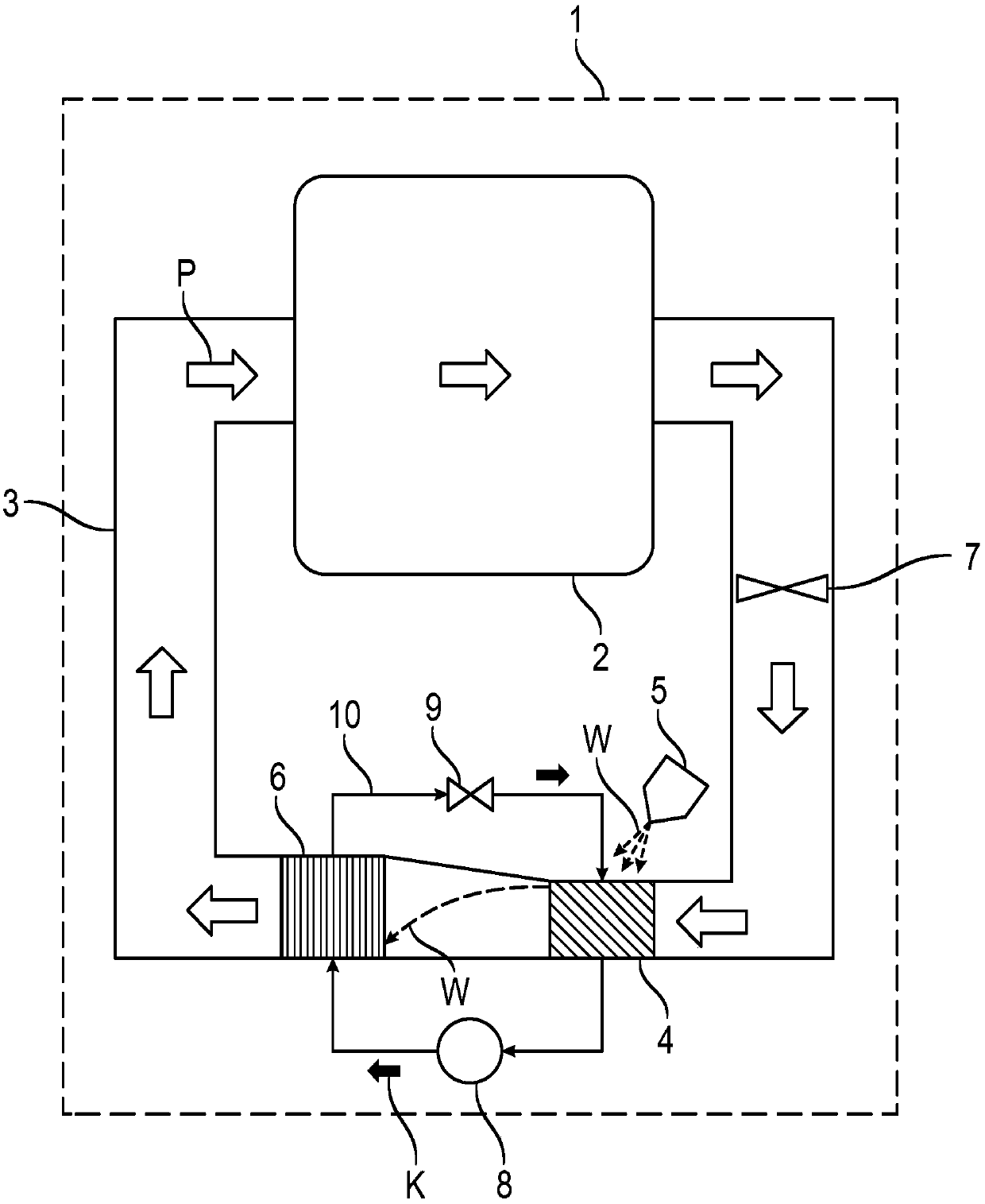

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

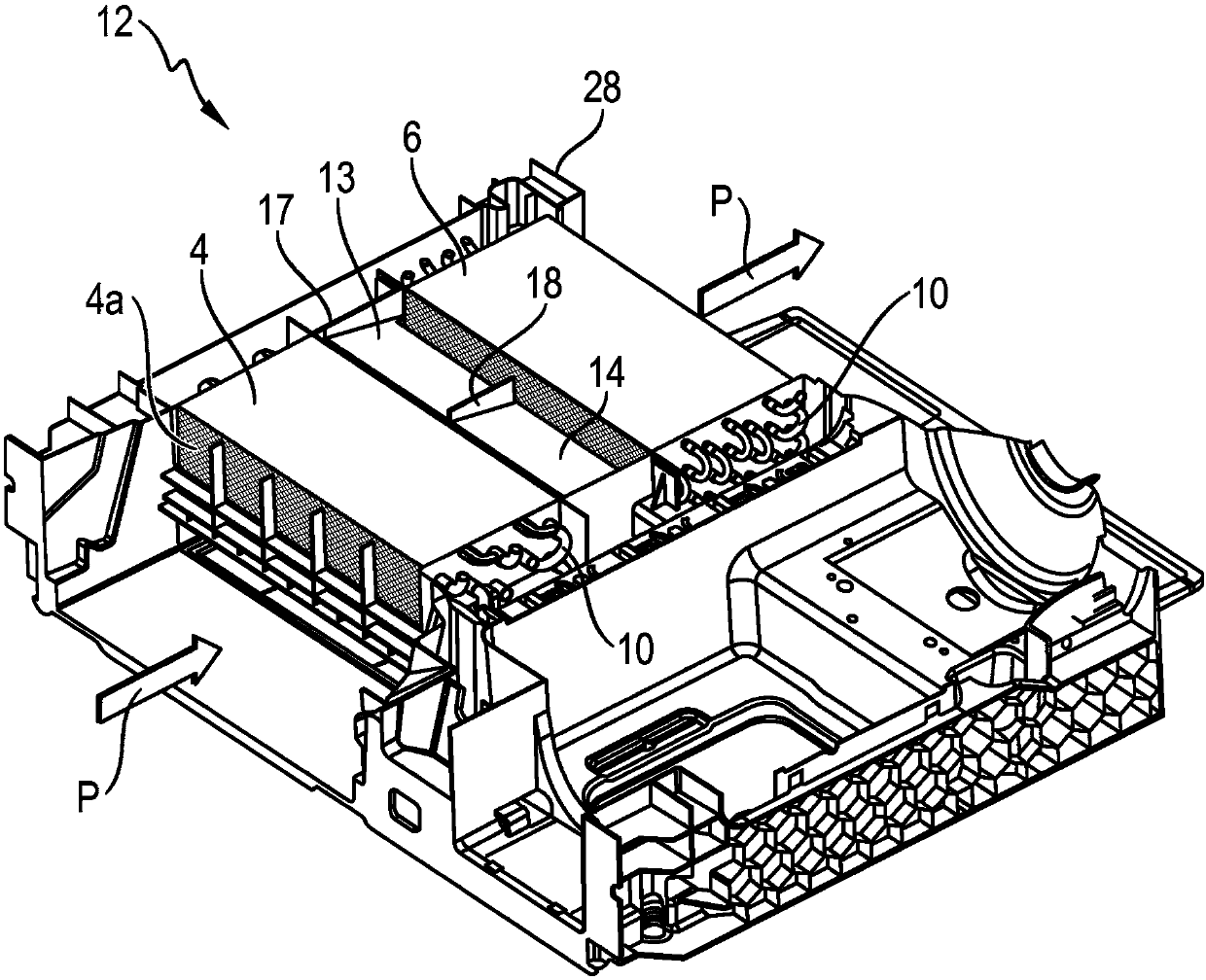

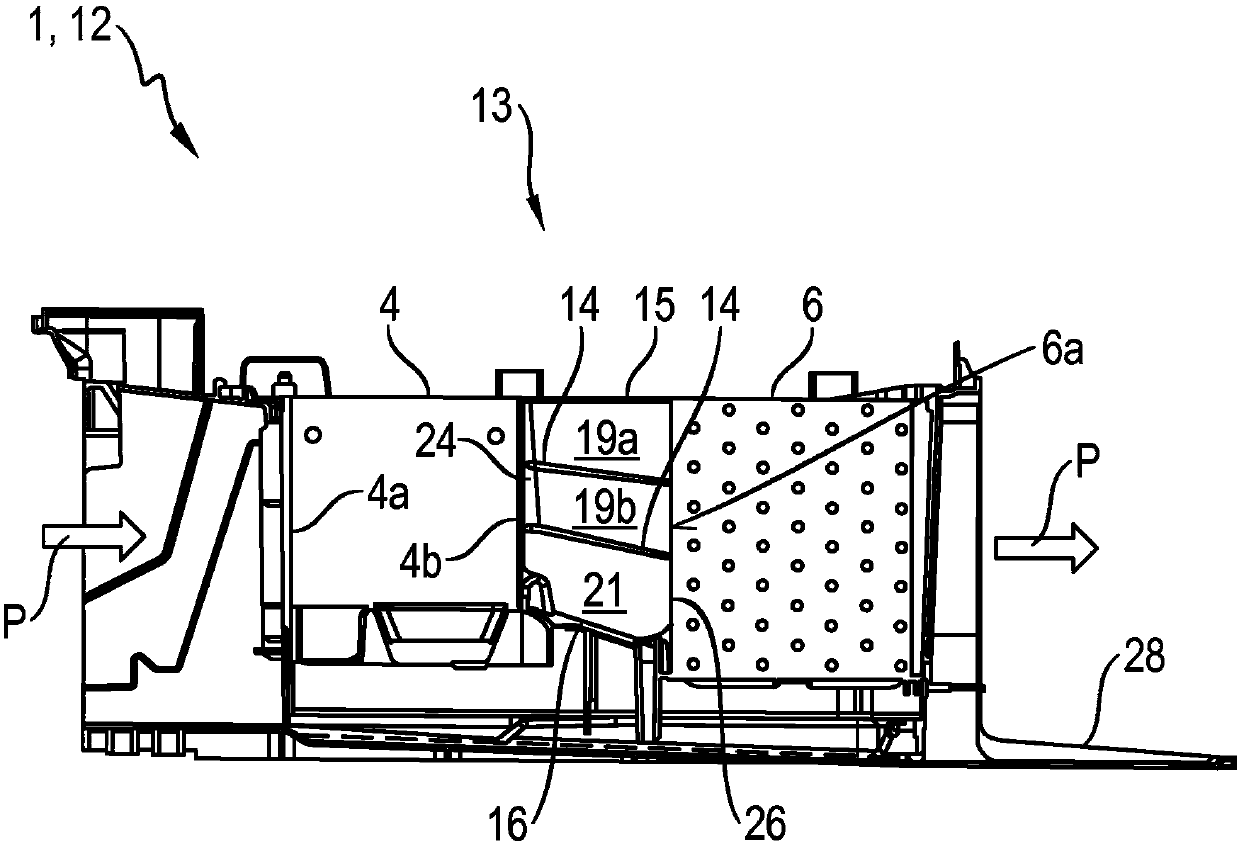

[0053] figure 2 Shown obliquely from above is a partial view of a base unit 12 of a heat pump dryer 1 , which has a first heat exchanger 4 and which is arranged at a distance in the flow direction of the process air P on said base unit 12 . The second heat exchanger 6 behind the first heat exchanger. In this case, a flow-guiding structure 13 is additionally arranged between the two heat exchangers. The associated sectional plane lies in the horizontal plane such that the top cover of the air guiding structure 13 is cut away and is therefore not shown. That is to say, the upper side of the air guiding structure 13 is shown open.

[0054] The first heat exchanger 4 has a square basic shape. Moist process air P enters at its air inlet face 4 a and is cooled and completely condensed there. The process air P then flows through the flow-guiding structure 13 and through the second heat exchanger 6 , where it is heated. The second heat exchanger 6 likewise has a square basic sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com