Smoke pipe filtering device with automatic ash cleaning function

An automatic dust removal and filtration device technology, which is applied in the direction of dispersed particle filtration, transportation and packaging, and separation of dispersed particles, can solve the problems of low filter usage rate, weak dust removal function, etc., to save dust time, The effect of ingenious structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

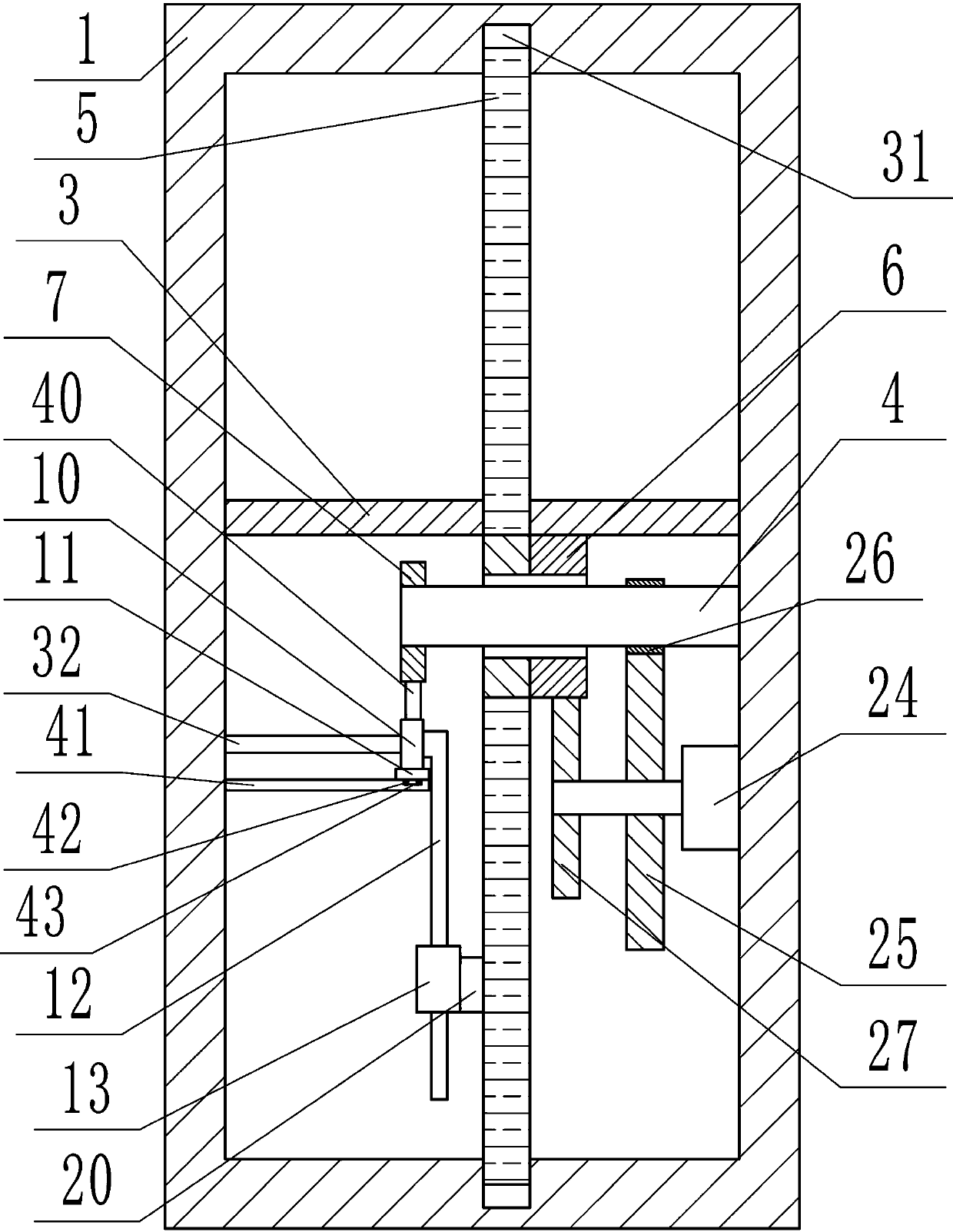

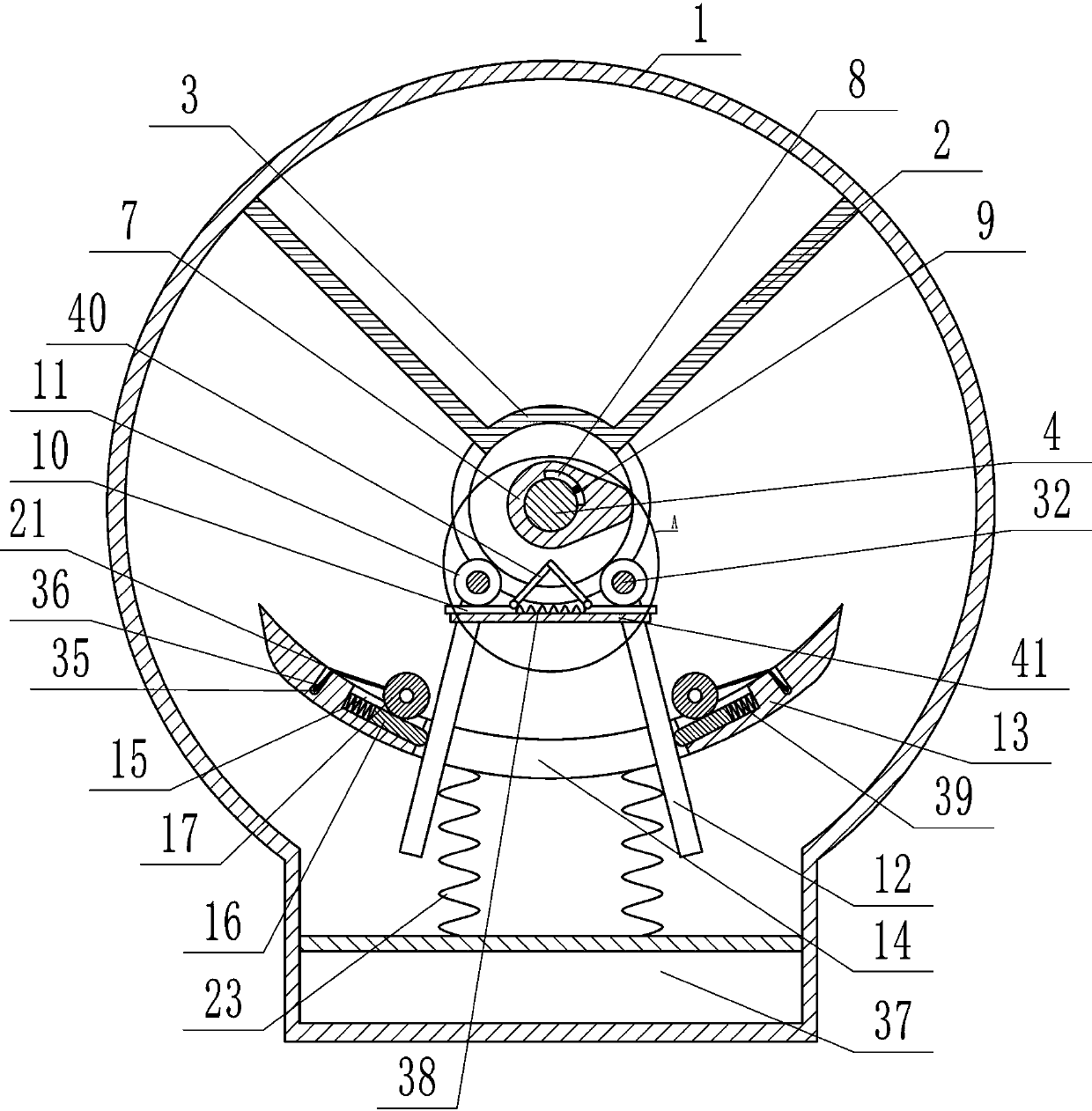

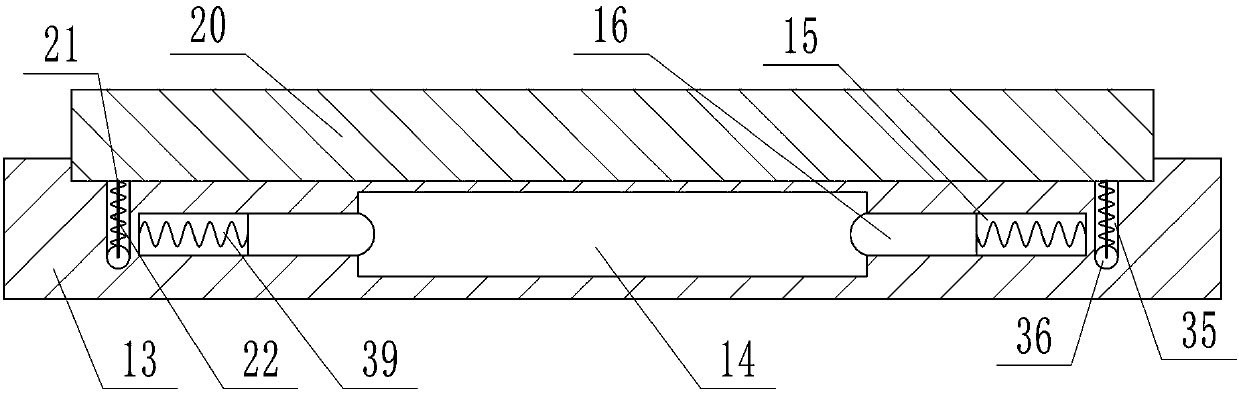

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Depend on Figure 1 to Figure 9 Provided, the present invention includes a cylinder 1 placed horizontally and closed at both ends, two partitions 2 facing the center of the cylinder 1 are installed at intervals on the inner wall of the cylinder 1, and the two partitions 2 are close to the center of the cylinder 1. One end is connected by an arc-shaped plate 3, the partition plate 2, the arc-shaped plate 3 and the inner wall of the cylinder 1 form a closed fan-shaped channel, the fan-shaped channel runs through the left and right ends of the cylinder 1, and a rotatable core is installed in the center of the cylinder 1 Shaft 4, a rotatable filter disc 5 is installed on the inner wall of the cylinder 1, a part of the filter disc 5 is placed in the fan-shaped channel, the filter disc 5 is not in contact with the mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com