A cement-sand mixing equipment for road facilities base

A technology for road facilities and mixing equipment, which is applied in the direction of cement mixing devices, clay preparation devices, chemical instruments and methods, etc., and can solve the problems of uneven mixing of sand and cement, and inability to uniformly control the amount of cement mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

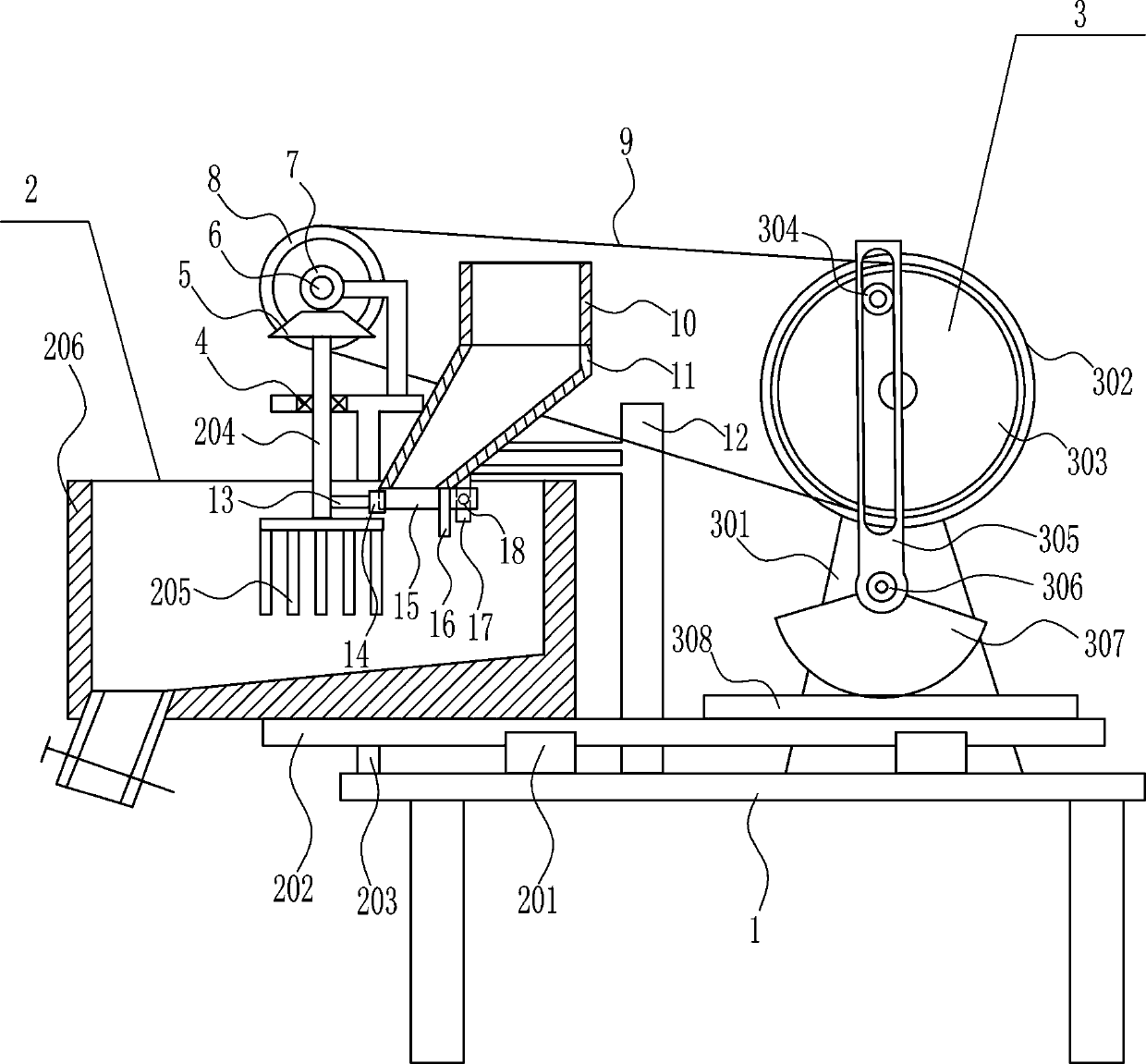

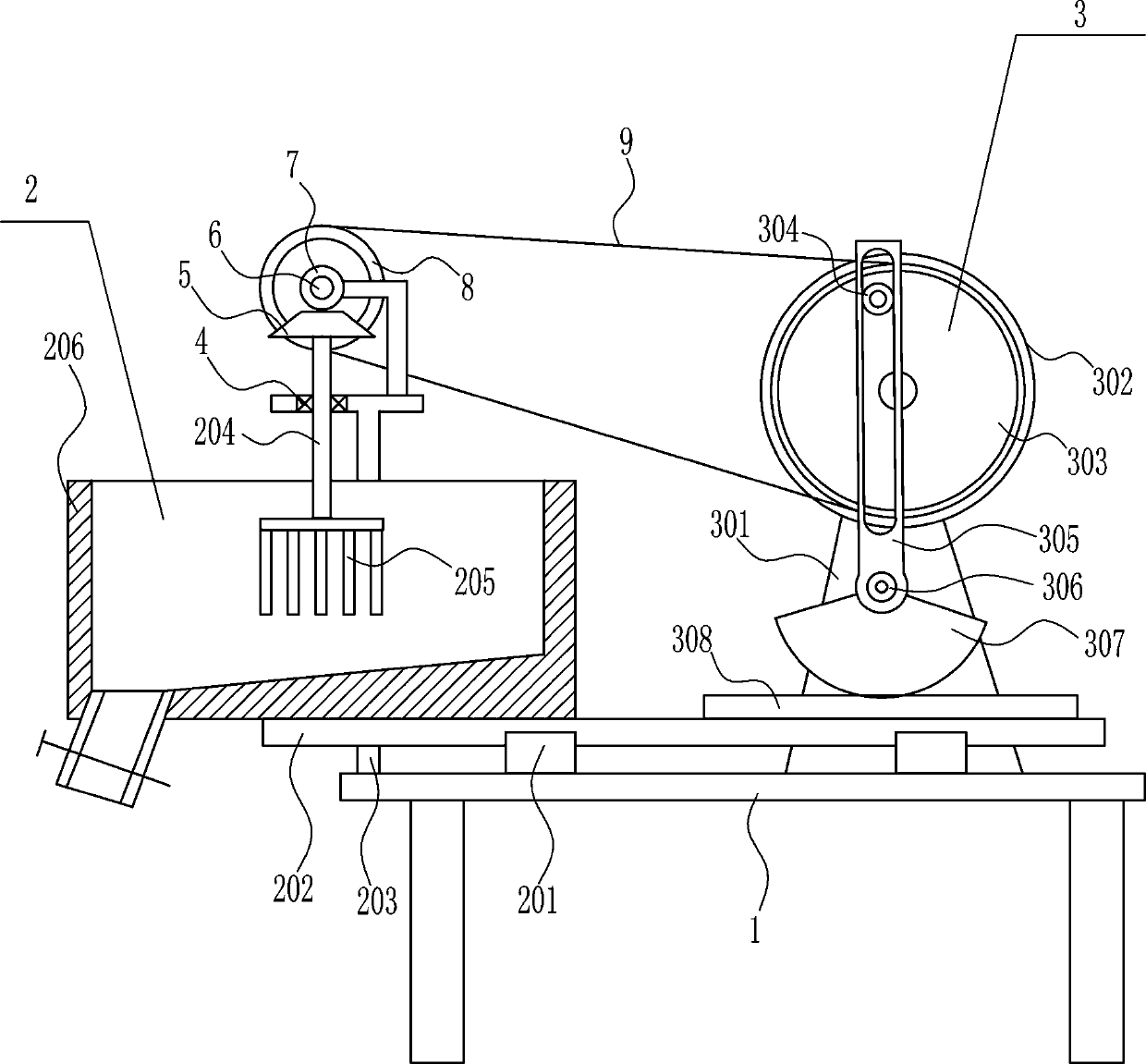

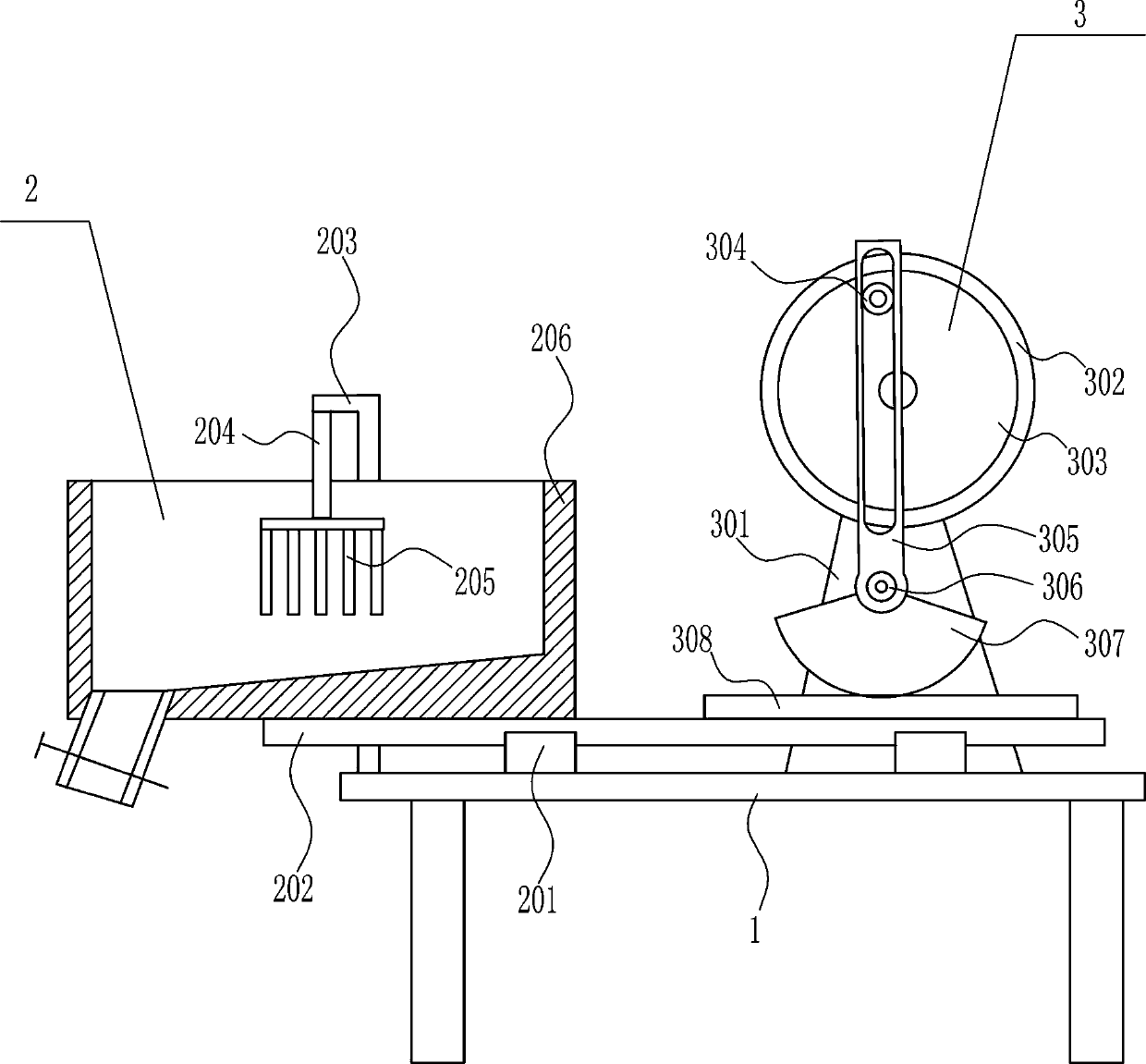

[0032] A cement-sand mixing equipment for the base of road facilities, such as Figure 1-5As shown, it includes an installation platform 1 , a mixing mechanism 2 and a driving mechanism 3 , the mixing mechanism 2 is connected to the top left side of the installation platform 1 , and the driving mechanism 3 is connected to the top right side of the installation platform 1 .

Embodiment 2

[0034] A cement-sand mixing equipment for the base of road facilities, such as Figure 1-5 As shown, it includes an installation platform 1 , a mixing mechanism 2 and a driving mechanism 3 , the mixing mechanism 2 is connected to the top left side of the installation platform 1 , and the driving mechanism 3 is connected to the top right side of the installation platform 1 .

[0035] The mixing mechanism 2 includes a slide block 201, a slide rail 202, a first fixed rod 203, a connecting rod 204, a mixing rod 205 and a mixing box 206. Rail 202, a mixing box 206 is connected to the top left side of the slide rail 202, a first fixed rod 203 is connected to the top left side of the installation table 1, a connecting rod 204 is connected to the upper side of the first fixing rod 203, and a mixing rod is connected to the bottom of the connecting rod 204 205 , the mixing rod 205 is located in the mixing box 206 .

Embodiment 3

[0037] A cement-sand mixing equipment for the base of road facilities, such as Figure 1-5 As shown, it includes an installation platform 1 , a mixing mechanism 2 and a driving mechanism 3 , the mixing mechanism 2 is connected to the top left side of the installation platform 1 , and the driving mechanism 3 is connected to the top right side of the installation platform 1 .

[0038] The mixing mechanism 2 includes a slide block 201, a slide rail 202, a first fixed rod 203, a connecting rod 204, a mixing rod 205 and a mixing box 206. Rail 202, a mixing box 206 is connected to the top left side of the slide rail 202, a first fixed rod 203 is connected to the top left side of the installation table 1, a connecting rod 204 is connected to the upper side of the first fixing rod 203, and a mixing rod is connected to the bottom of the connecting rod 204 205 , the mixing rod 205 is located in the mixing box 206 .

[0039] Drive mechanism 3 comprises mount 301, motor 302, running whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com