Inserting-type strip-shaped buckle plate steel structure and assembling method

A plug-in, steel structure technology, used in building components, building structures, buildings, etc., can solve the problems of low stability, inconvenience, and inability to adapt to the installation of strip gussets of different widths, achieving high stability and splicing. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

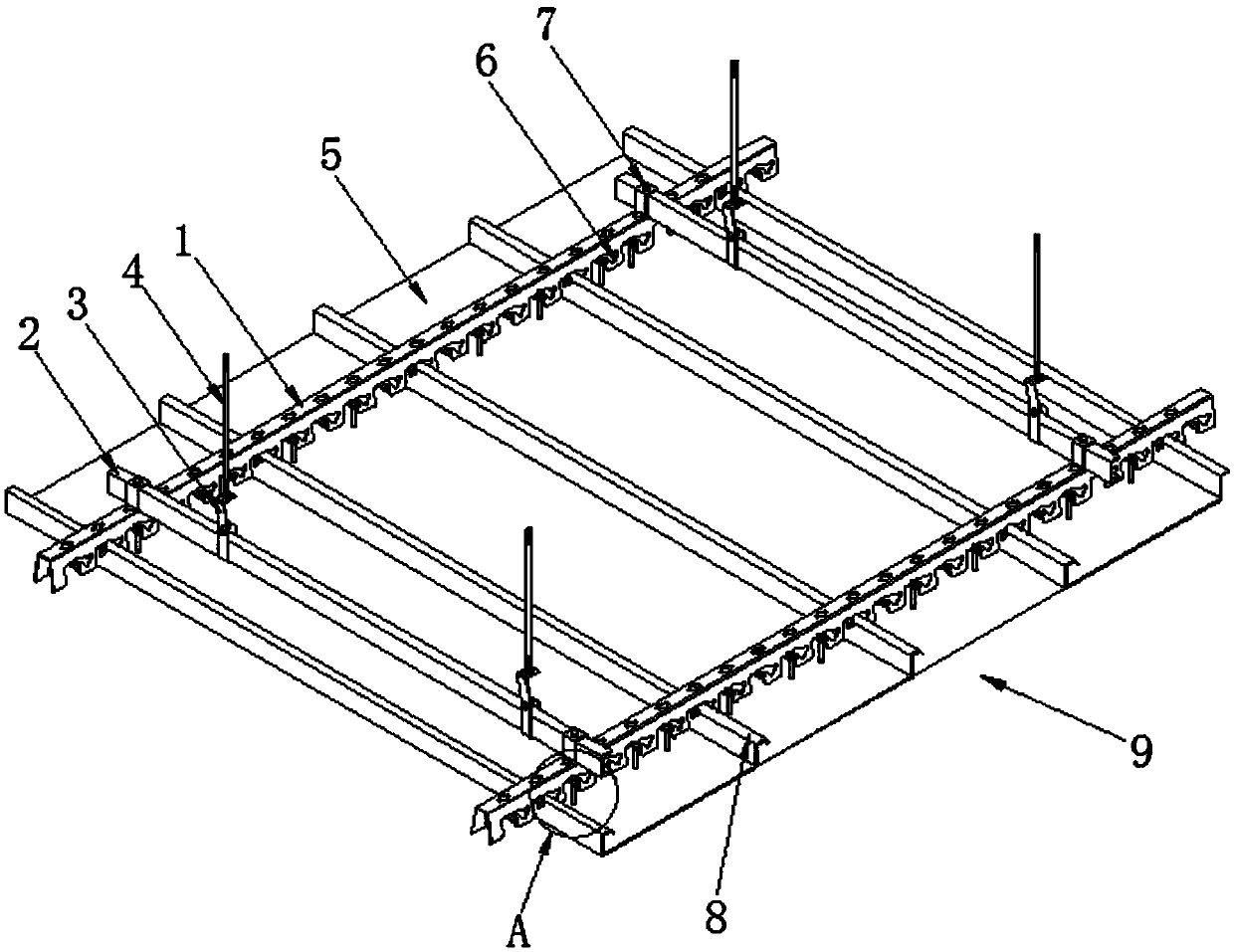

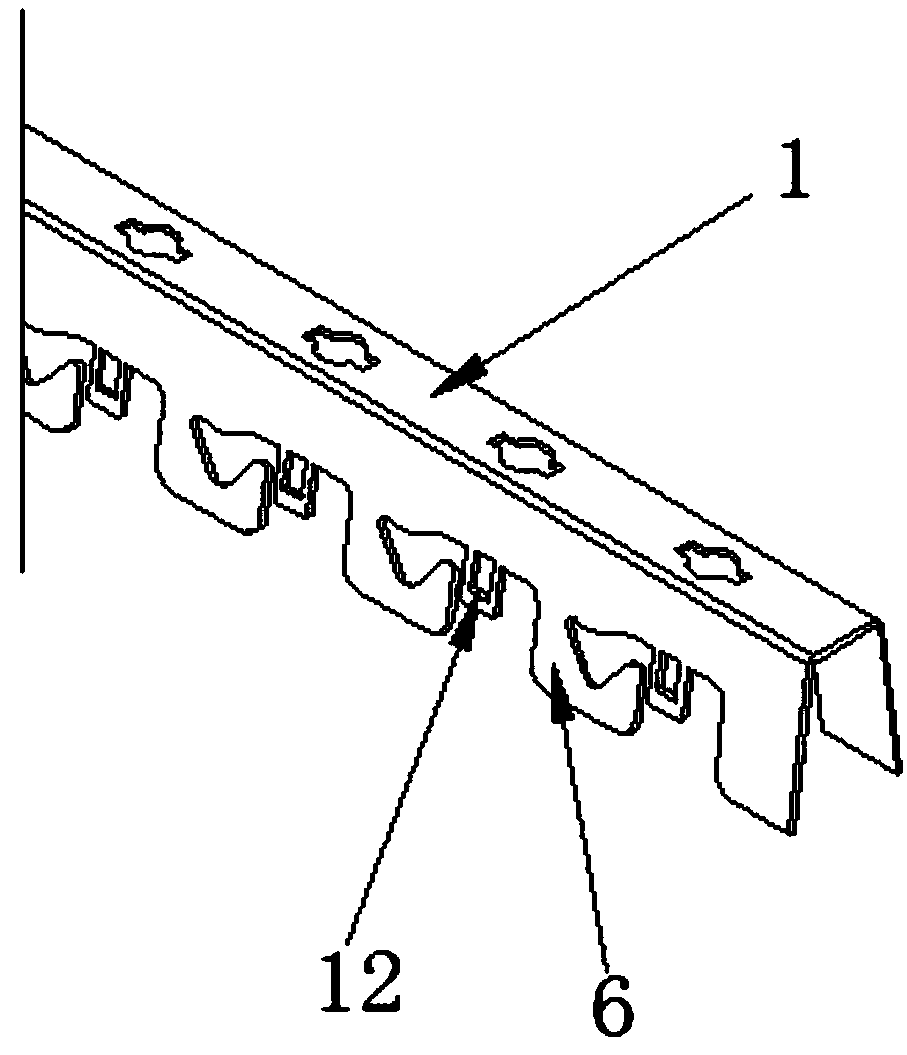

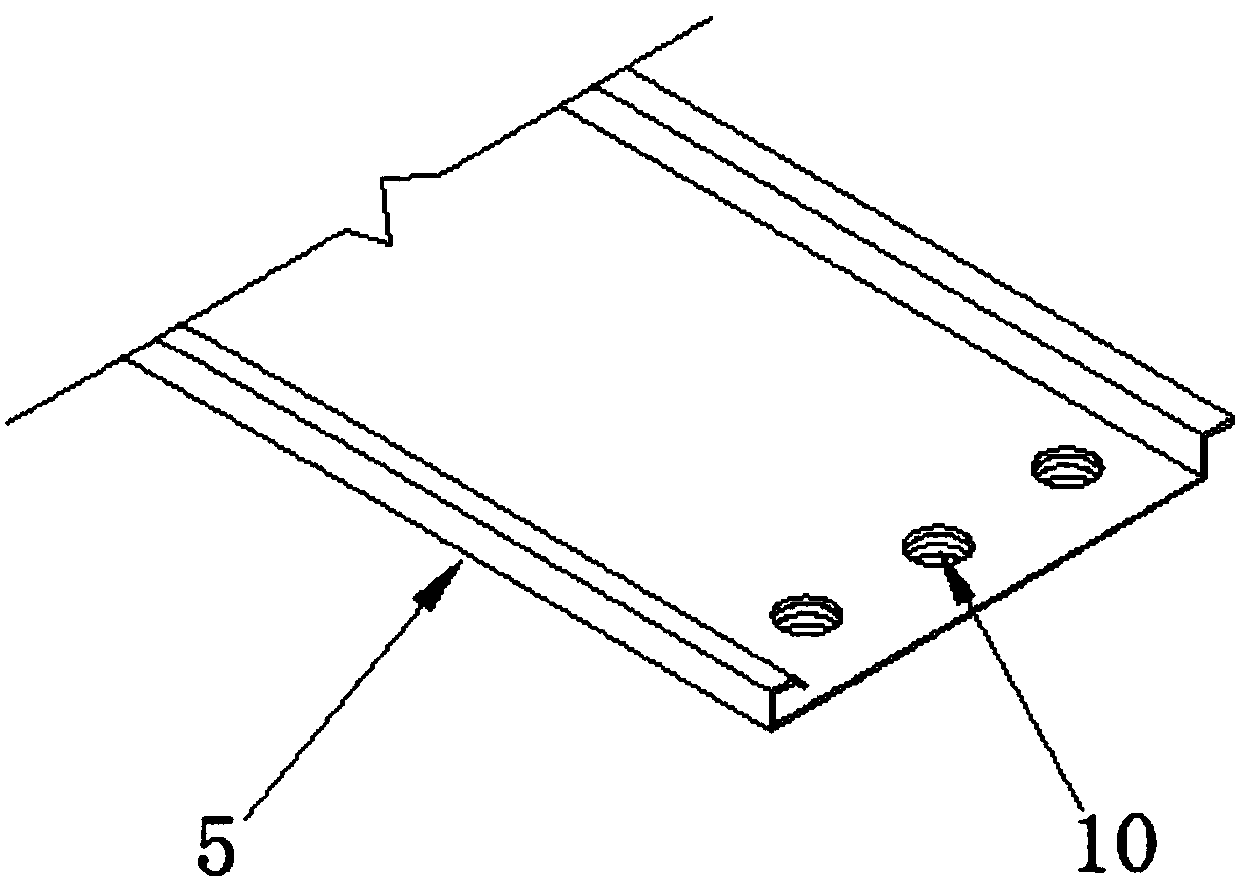

[0028] like Figure 1 to Figure 5 As shown, a plug-in strip gusset steel structure provided by the embodiment of the present invention includes a strip gusset keel 1, a light steel keel 2, a light steel keel hanger 3, a boom 4, a strip gusset 5, Hook 6, bolt 7, edge slat 8, ceiling structure body 9, bar gusset keel connection code 10, threaded slot hole 11, fixing stud 12 and limit ear seat 13, and described ceiling structure body 9 comprises two A strip gusset keel 1, two light steel keels 2 and several strip gussets 5; the strip gusset keel 1 is fixedly connected with the light steel keel 2 by bolts 7; the light steel keel 2 The light steel keel hanger 3 is fixed on the top; the light steel keel hanger 3 is threadedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com