Door frame self-locking splicing structure

A door frame and self-locking technology, applied in the direction of windows/doors, building components, building structures, etc., can solve the problems of poor punching, difficult hole position accuracy, high cost, etc., to avoid processing procedures, simple assembly, and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Figure 6 It is an exploded view of the traditional assembly structure. It can be seen that the door frame 2 and the corner bracket 5 have corresponding screw holes. During the splicing and screwing process, strict alignment of the holes is required, and the screw heads will be exposed.

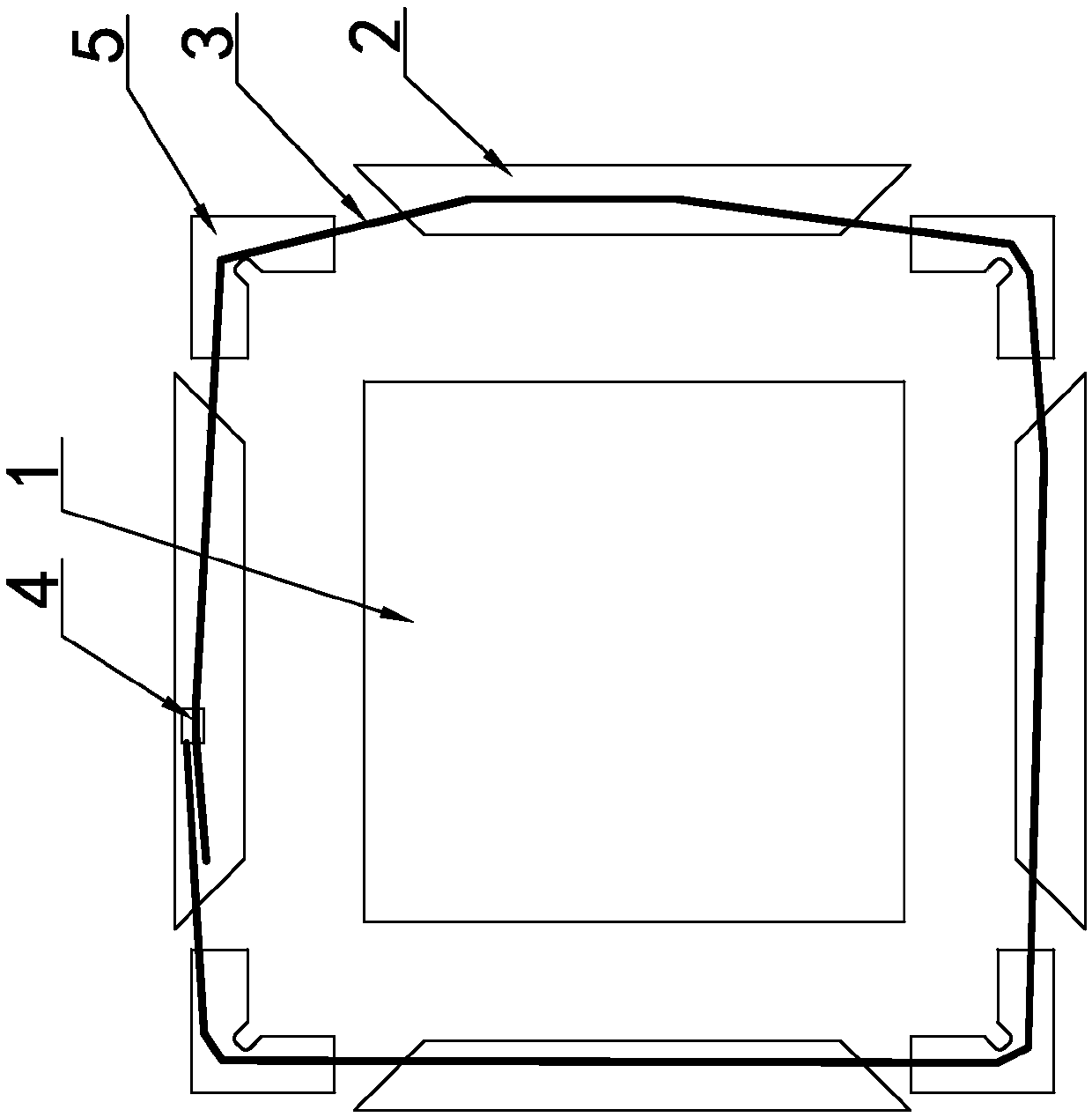

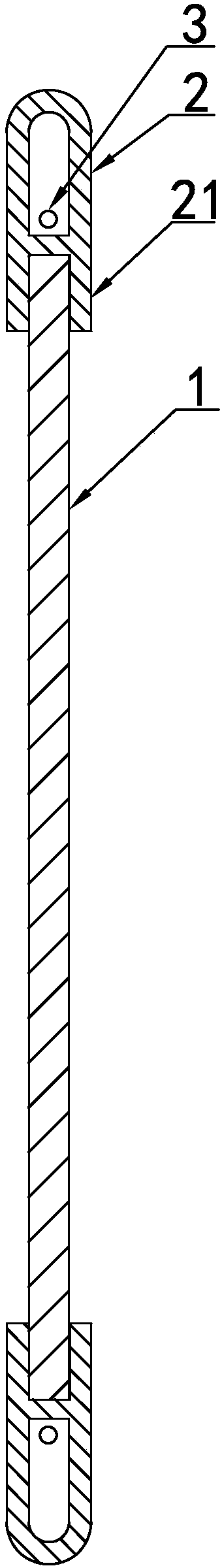

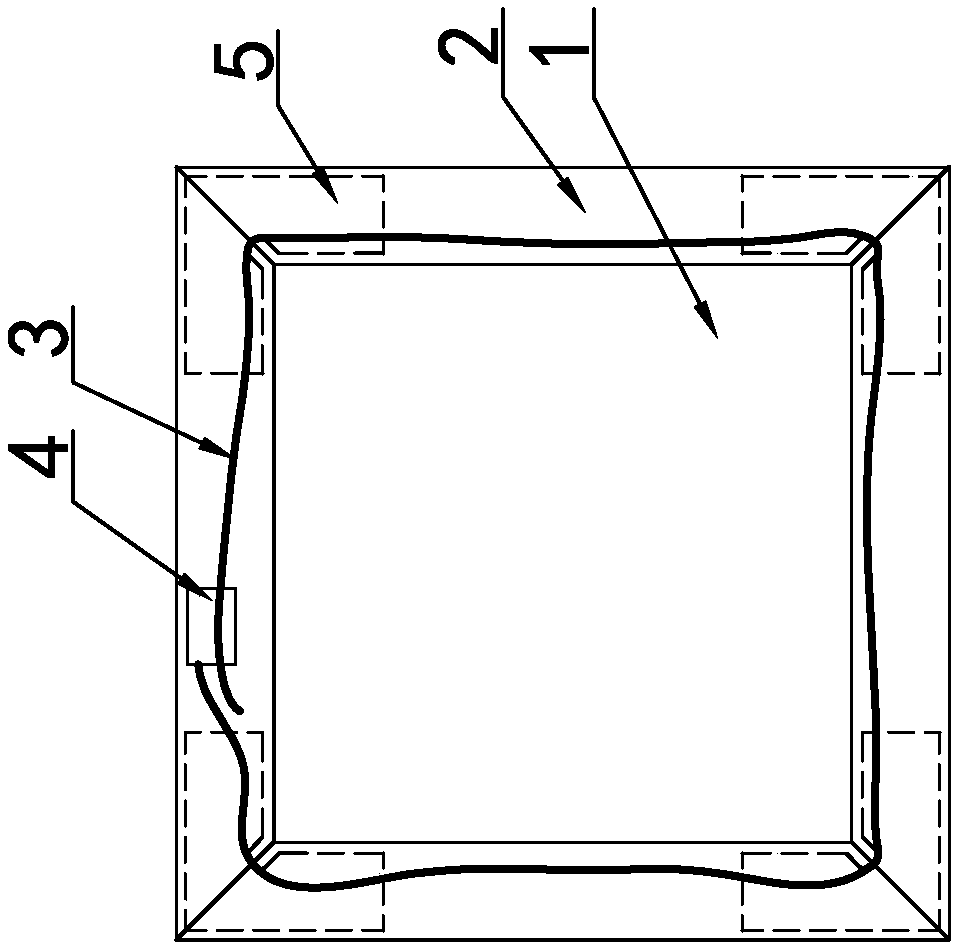

[0020] refer to Figure 1 to Figure 5 , the present invention is a door frame self-locking assembly structure, including a number of door frames 2 for clamping around the door panel 1 and ropes 3 passing through each door frame 2 in sequence, one door frame 2 is provided with a one-way self-locking module 4, one-way The self-locking module 4 includes a fixed end and a one-way sliding end, one end of the rope 3 is connected to the fixed end, and the other end of the rope 3 passes through the one-way sliding end to realize one-way movement.

[0021] The one-way self-locking module 4 enables the rope 3 to shrink gradually. When the rope 3 passes through the door frame 2, the door frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com