Three-way impact-resisting support for high-temperature pipeline system

A high-temperature tube, shock-resistant technology, applied in the directions of pipe supports, pipes/pipe joints/pipes, springs/shock absorbers, etc. Capability, low cost, effect of improving stability and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

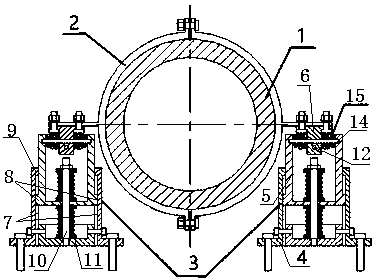

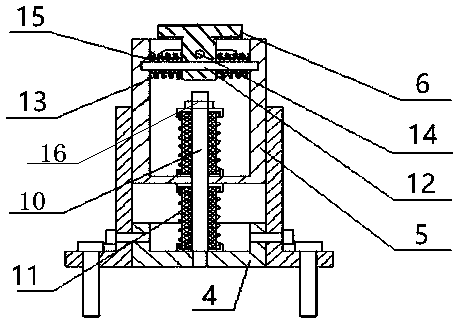

[0016] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

[0017] Such as figure 1 , figure 2 As shown, the device in this embodiment includes: pipe clamp 2 and two three-way impact-resistant brackets 3; 2 is snapped on the outer periphery of the pipe 1 of the high-temperature pipeline system; the three-way impact-resistant bracket 3 includes: the hollow base 4 with the opening facing upwards, the hollow sleeve 5 and the slider 6 with the opening facing upwards; the base 4 and the sleeve 5 pass through A pair of Z-direction chute pairs 7 arranged symmetrically on the inner wall of the base 4 and vertically perpendicular to the extension direction of the high-temperature pipeline system pipes and a pair of Z-direction protrusions 8 arranged on the sleeve form a sliding connection. 4 There is a limit part A9 at the opening to prevent the base 4 and the sleeve 5 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com