Power-on test device for an integrated lamp strip

A power-on test and integrated technology, applied in the direction of measuring devices, instruments, etc., can solve the problem of insufficient test points, etc., and achieve the effect of accurate test results and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

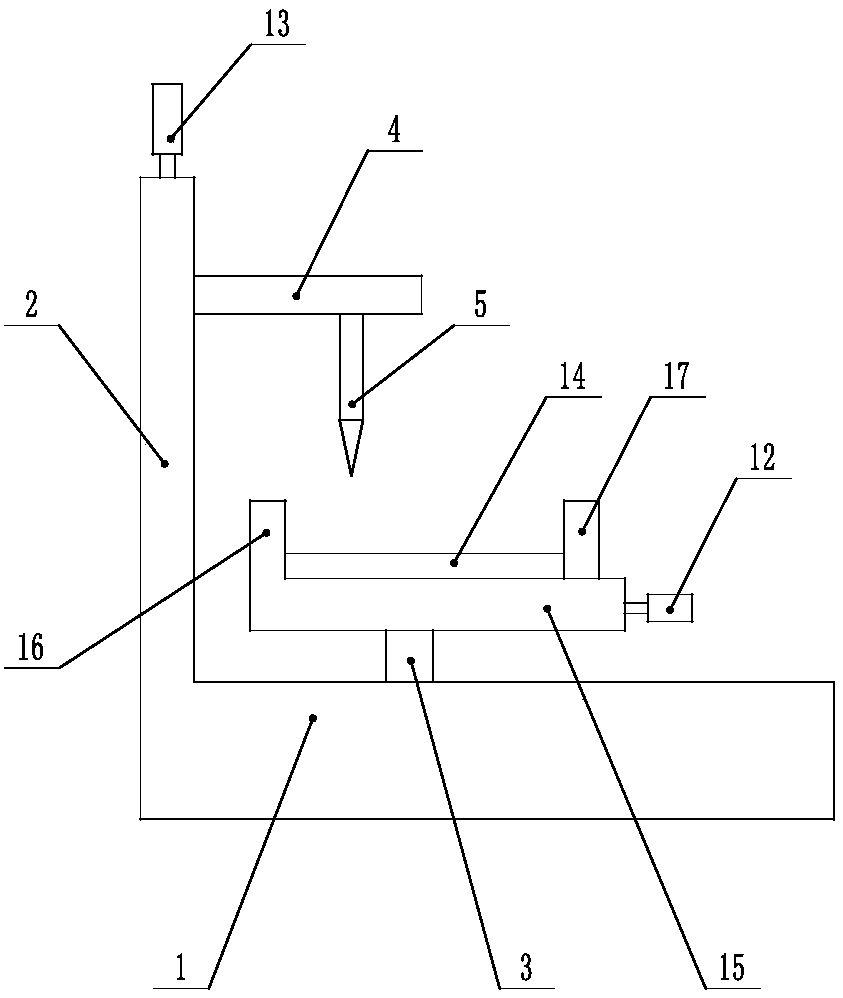

[0024] Such as figure 1 As shown, the electrification test equipment suitable for integrated light strips includes a base 1, a support plate 2 is fixedly arranged on the base 1, a rotating shaft 3 is arranged on the base 1, and a placing plate 15 is arranged on the rotating shaft 3, and the placing plate 15 can The rotating shaft 3 rotates around its axial direction together, and one end of the placing disc 15 is provided with a fixed baffle 16, and the other end is provided with a movable baffle 17, and the movable baffle 17 can move along the surface of the placing disc 15 or be fixed on the placing disc 15; The support plate 2 is provided with a movable mounting plate 4, and the movable mounting plate 4 can move along the support plate 2 or be fixed on the support plate 2; the movable mounting plate 4 is provided with a height detection head 5; the movable mounting plate 4 is provided with a groove, the height detection head 5 is provided with a protrusion, the groove is fi...

Embodiment 2

[0027] This embodiment is based on Embodiment 1 to further illustrate the present invention.

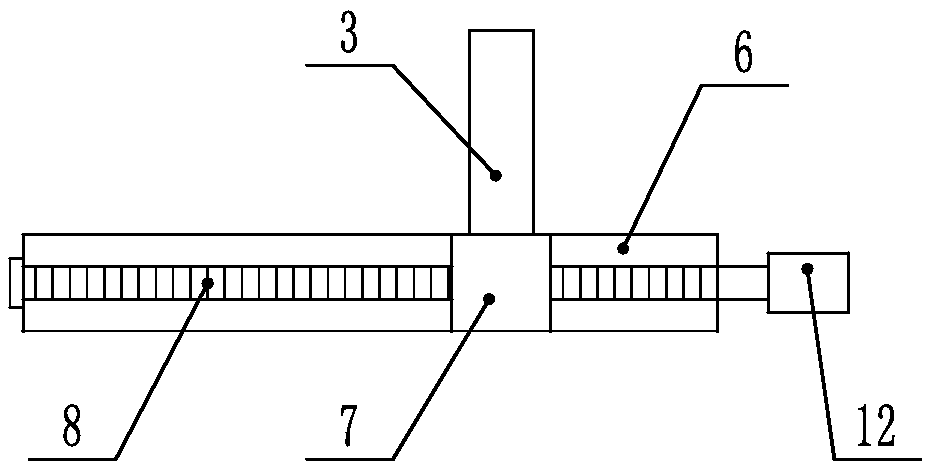

[0028] Such as figure 2 As shown, it is suitable for the electrification test equipment of the integrated light bar. The placement plate 15 is provided with a guide groove-6, and the guide groove-6 is provided with a sliding block-7, and the sliding block-7 is screwed with a screw rod-8. , one end of the screw one 8 is connected with the guide groove one 6, and the other end is located outside the placement plate 15, the screw one 8 can rotate around its own axis direction, so that the sliding block one 7 can move along the axis direction of the screw one 8, and the movable stop The plate 17 is fixed on the sliding block 17, and the position of the sliding block 17 and the movable baffle 17 can be adjusted by turning the screw rod 17, so that it is suitable for patch LED light strips 14 of different specifications and sizes, and the screw rod 18 is located at the One end outside th...

Embodiment 3

[0030] This embodiment is based on Embodiment 1 to further illustrate the present invention.

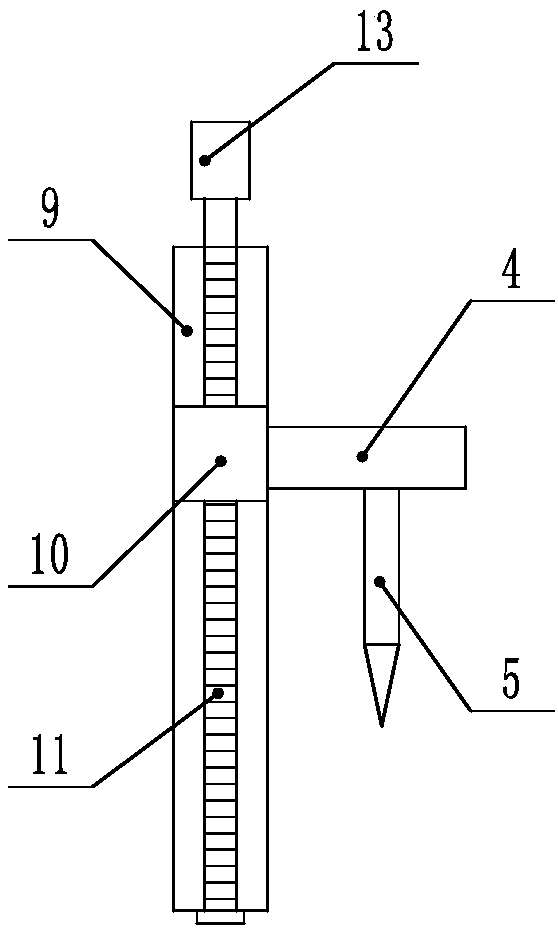

[0031] Such as image 3As shown, it is suitable for the electrification test equipment of the integrated light bar. The support plate 2 is provided with a guide groove 2 9, and the guide groove 2 9 is provided with a sliding block 2 10, and the sliding block 10 is screwed with a screw rod 2 11. One end of the screw 11 is connected to the guide groove 9, and the other end is located outside the support plate 2. The screw 11 can rotate around its own axis to make the sliding block 10 move along the axis of the screw 11. The movable installation The plate 4 is fixed on the sliding block 2 10, and the position of the sliding block 2 and the movable mounting plate can be adjusted by turning the screw 2, so that it is suitable for patch LED light strips of different sizes, and the screw 2 11 is located on the supporting plate 2 One end outside is provided with driving device 2 13, and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com