Energy measurement and calibration system for large-scale laser devices

An energy measurement and laser device technology, applied in the field of energy measurement and calibration systems, can solve the problems of low calibration linearity and photoelectric equivalence, lower device operating efficiency, high process requirements, etc., achieve air convection and small changes in ambient temperature, Reduce the possibility of interference and calibrate the effect of high linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

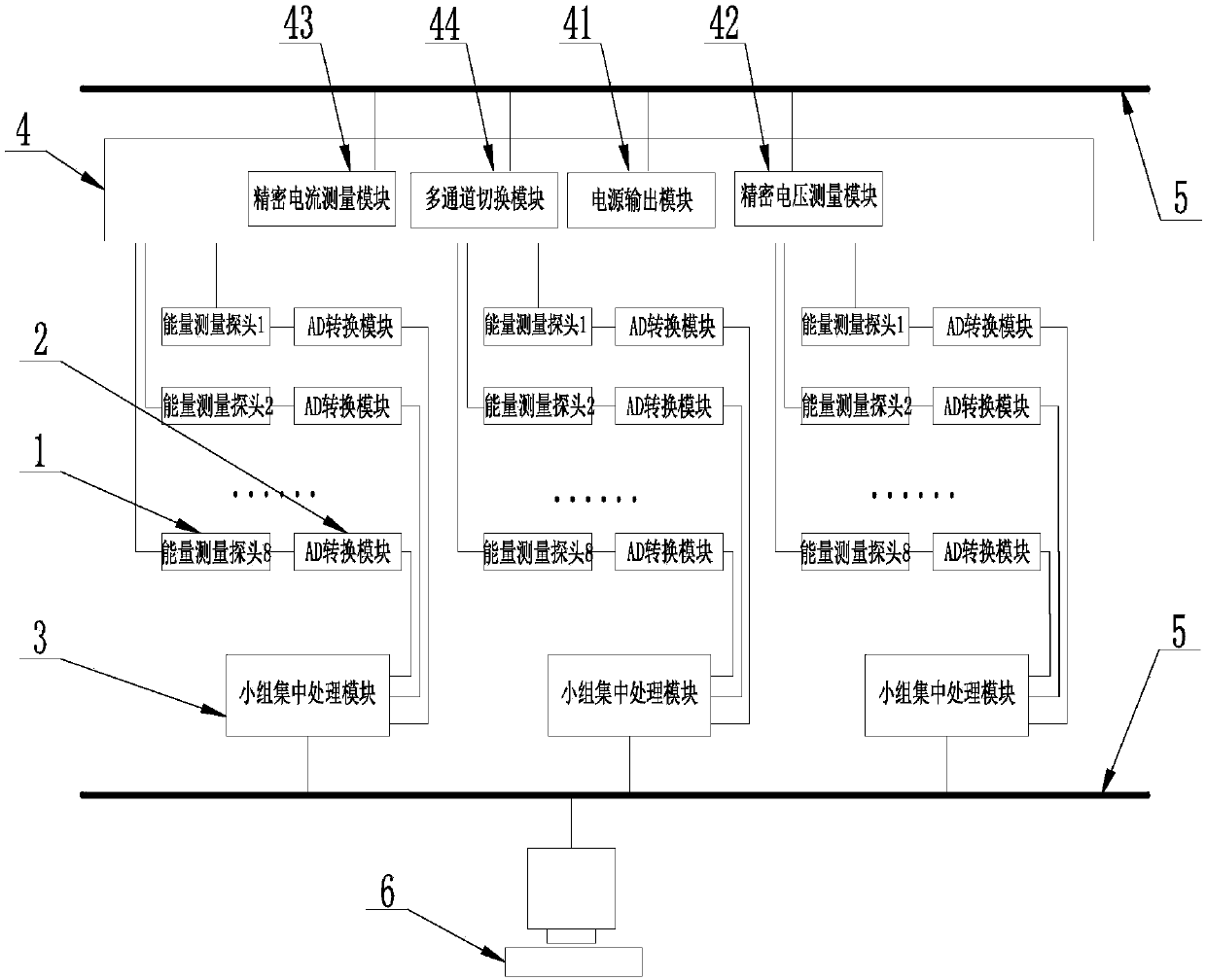

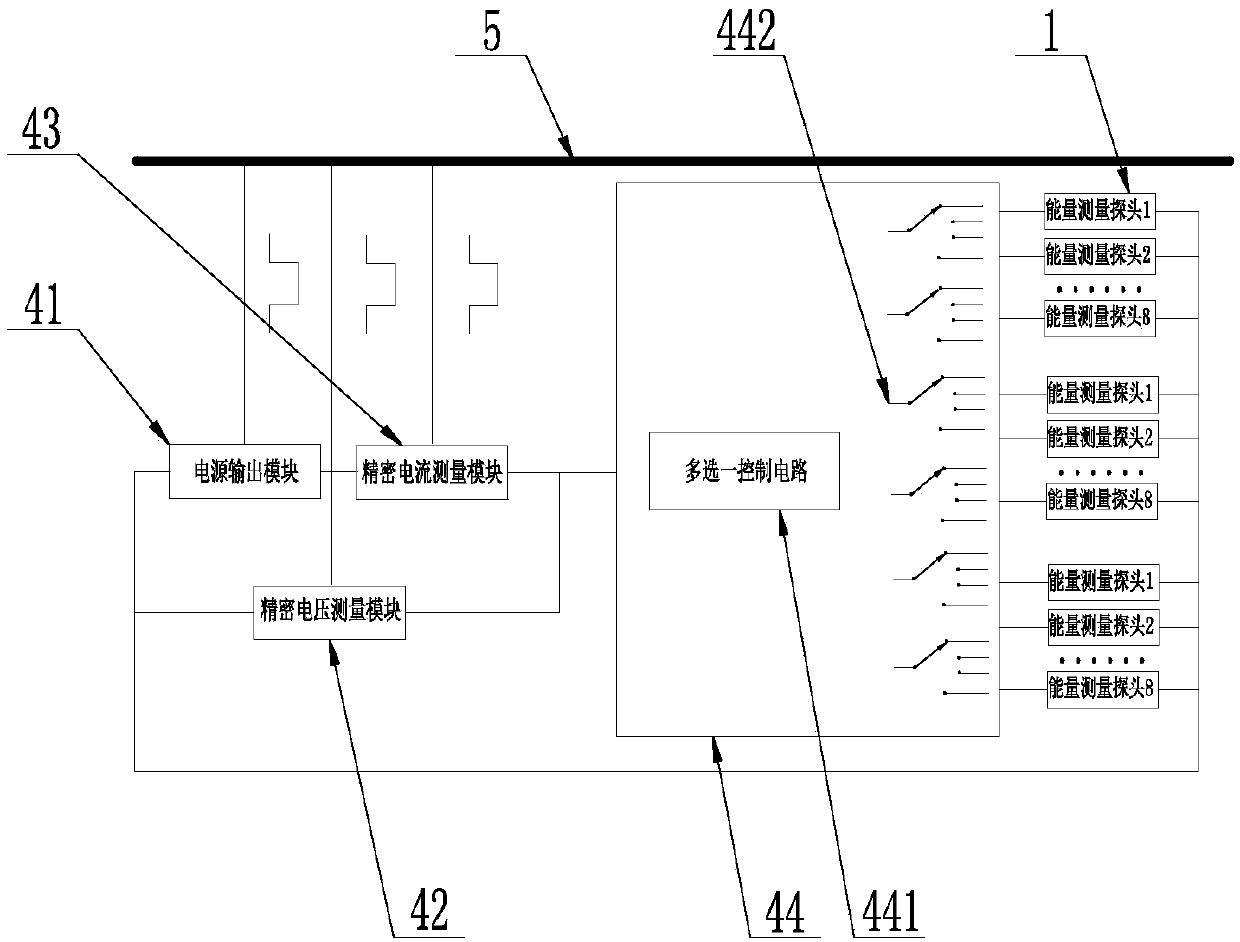

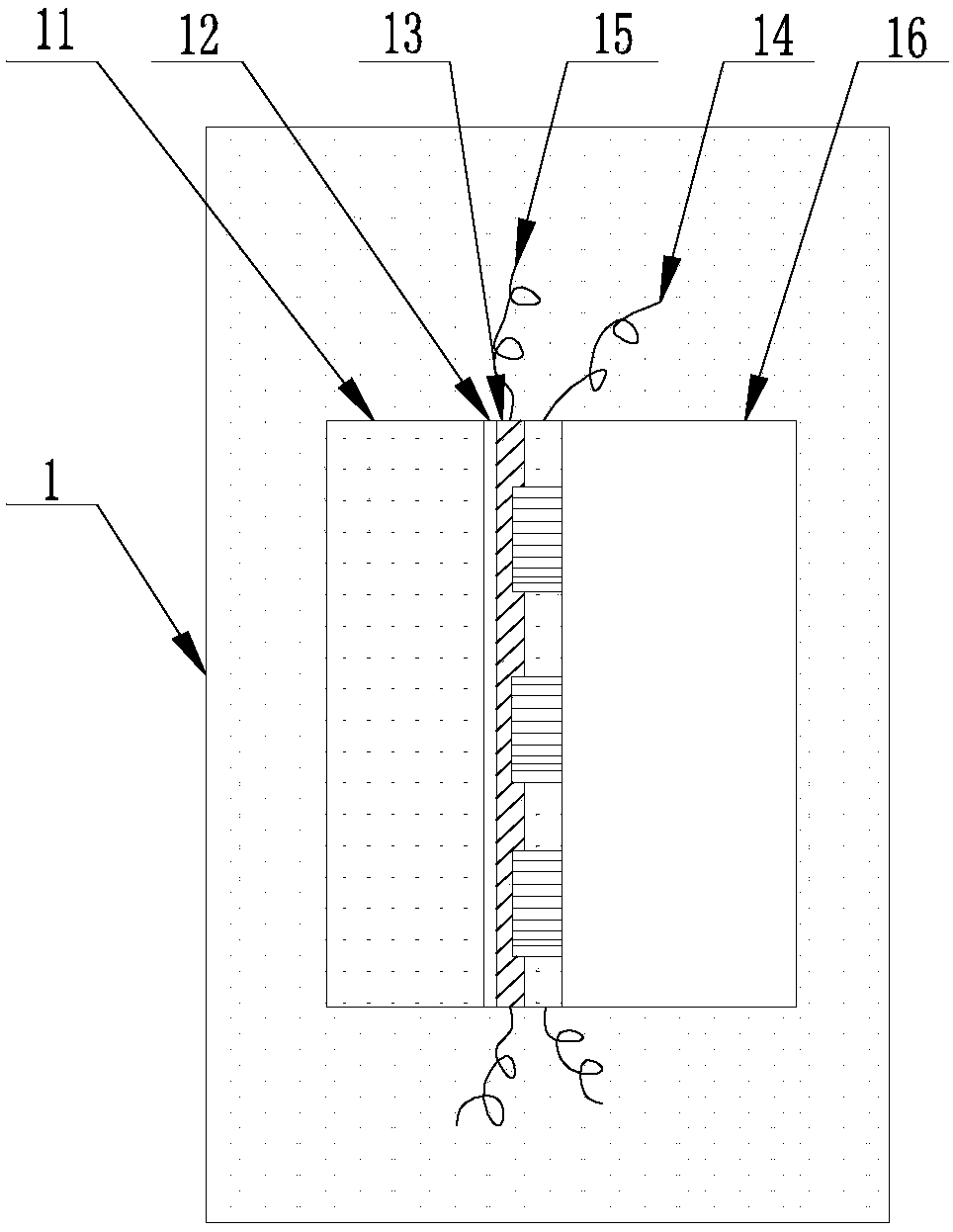

[0027] Such as figure 1 As shown, an energy measurement and calibration system for a large laser device includes an energy measurement probe 1, an AD conversion module 2, a group centralized processing module 3, an energy electrical calibration component 4, a backbone network 5, and an energy measurement and calibration control platform 6. The data transmission interface of the energy measurement probe 1 is sequentially connected to the AD conversion module 2, the group centralized processing module 3, and the backbone network 5. The electrical calibration interface of the energy measurement probe 1 is connected to the backbone network 5 through the energy electrical calibration component 4 The energy measurement and calibration control platform 6 is connected to the backbone network, and the group centralized processing module 3 is used to implement the system's requirements for hierarchical and grouping control, and is responsible for transmitting all data to the energy measure...

Embodiment 2

[0038] Such as Figure 5 As shown, the same parts of this embodiment and the first embodiment will not be repeated, the difference is:

[0039] The thin-foil return resistor 15 is arranged in a matrix array alternately with the sensor 14. This arrangement can achieve the same technical effect as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com