Rocker switch

A technology of rocker switches and elastic parts, which is applied to the parts of flip switches/rocker switches, etc., which can solve the problems of reducing the service life of switches, failure to break, and excessive burnout of switches, etc., so as to prolong the service life and ensure reliability. Strong and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

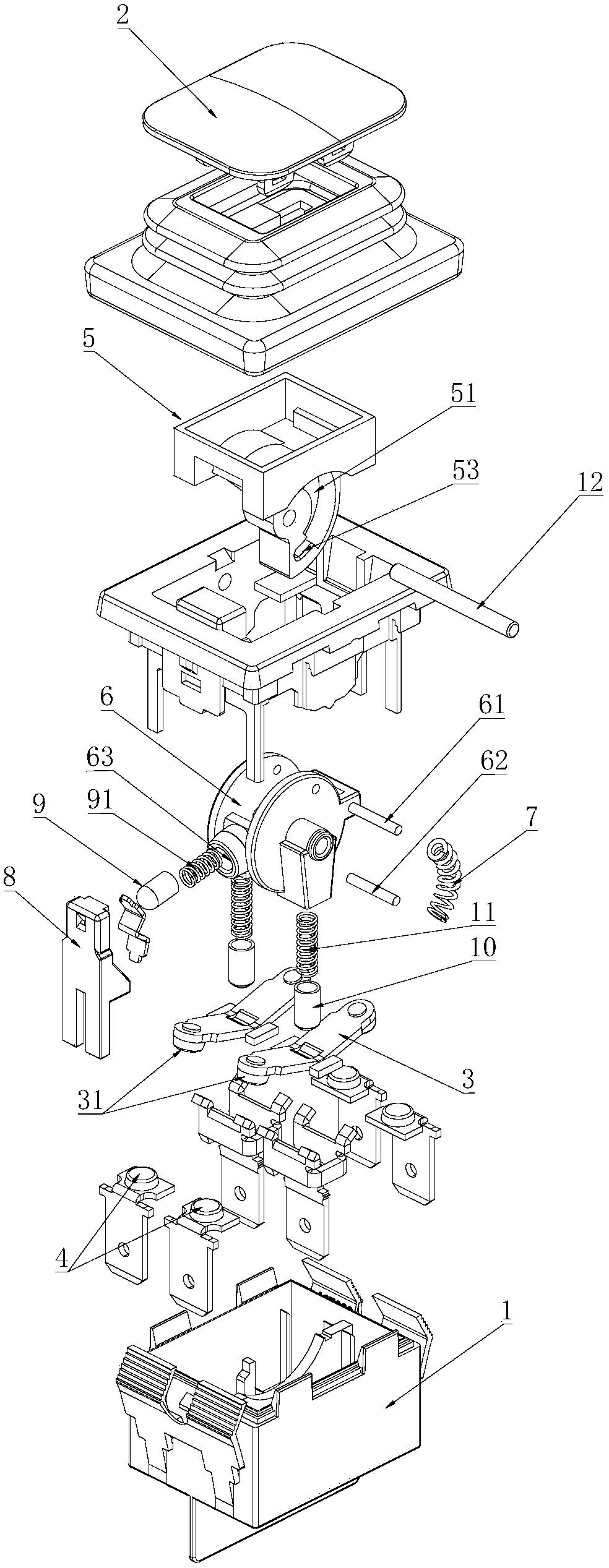

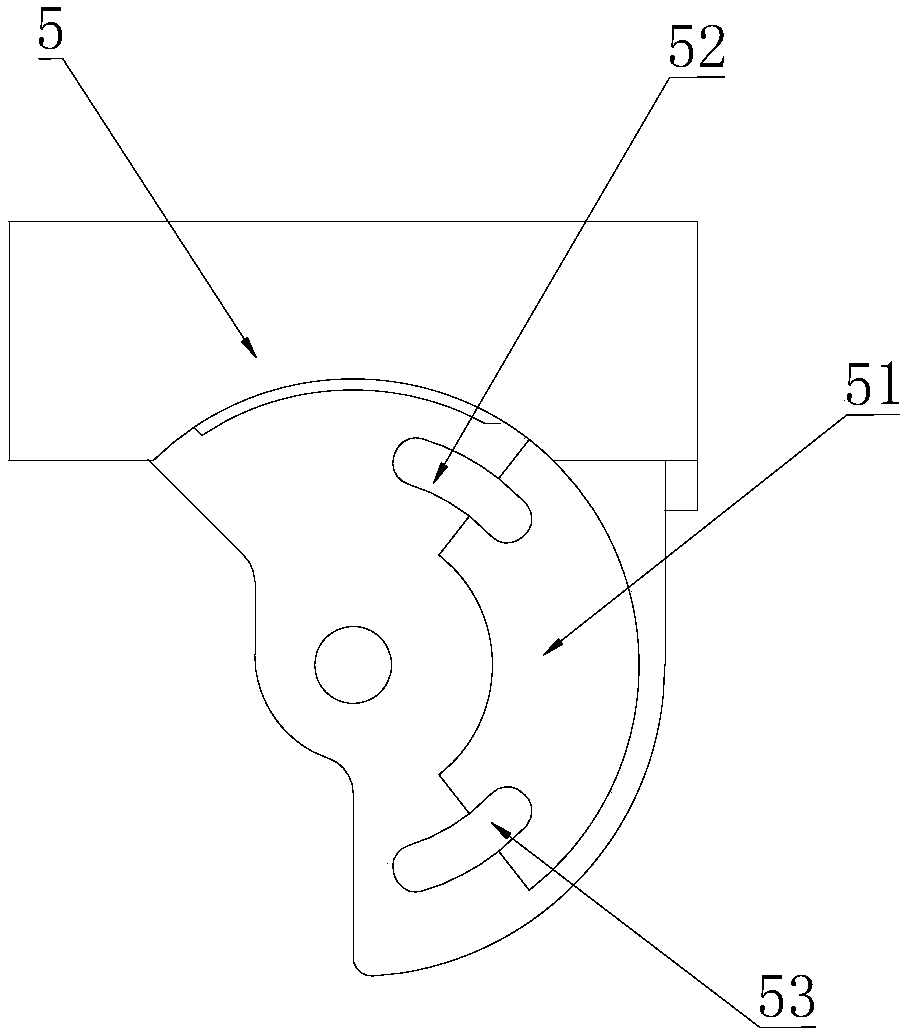

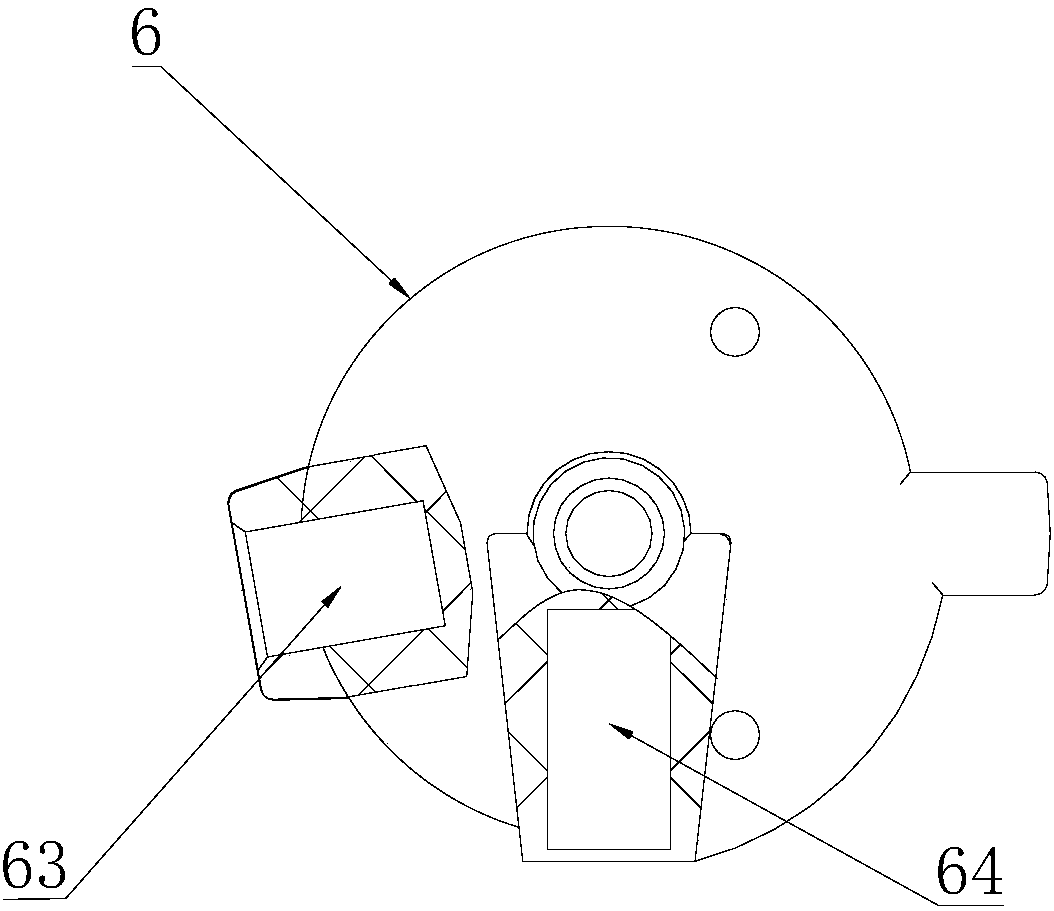

[0039] see figure 1 As shown, a rocker switch provided in this embodiment includes a switch base 1 and a switch cover covering the switch base 1, the button 2 is installed on the switch cover, the moving contact 31, the static contact 4, and the active part 5 , The follower 6 and the drive elastic 7 are installed in the switch base 1. Wherein, the driving elastic member 7 can be a spring, and the compression ratio of the spring can be 10%-90%. see figure 2 As shown, the active member 5 is provided with a driving slot 51 and a driving bar-shaped hole. There are two driving strip holes, respectively the upper driving hole 52 and the lower driving hole 52, the upper driving hole 52 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com