Fertilization equipment for rotary tillage

A device and carrier technology, which is applied in the field of rotary tillage and fertilization equipment, can solve the problems of fertilizer exposure to air and waste, and achieve the effects of good fertilization effect, prevention of loss and waste, and prevention of outward loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

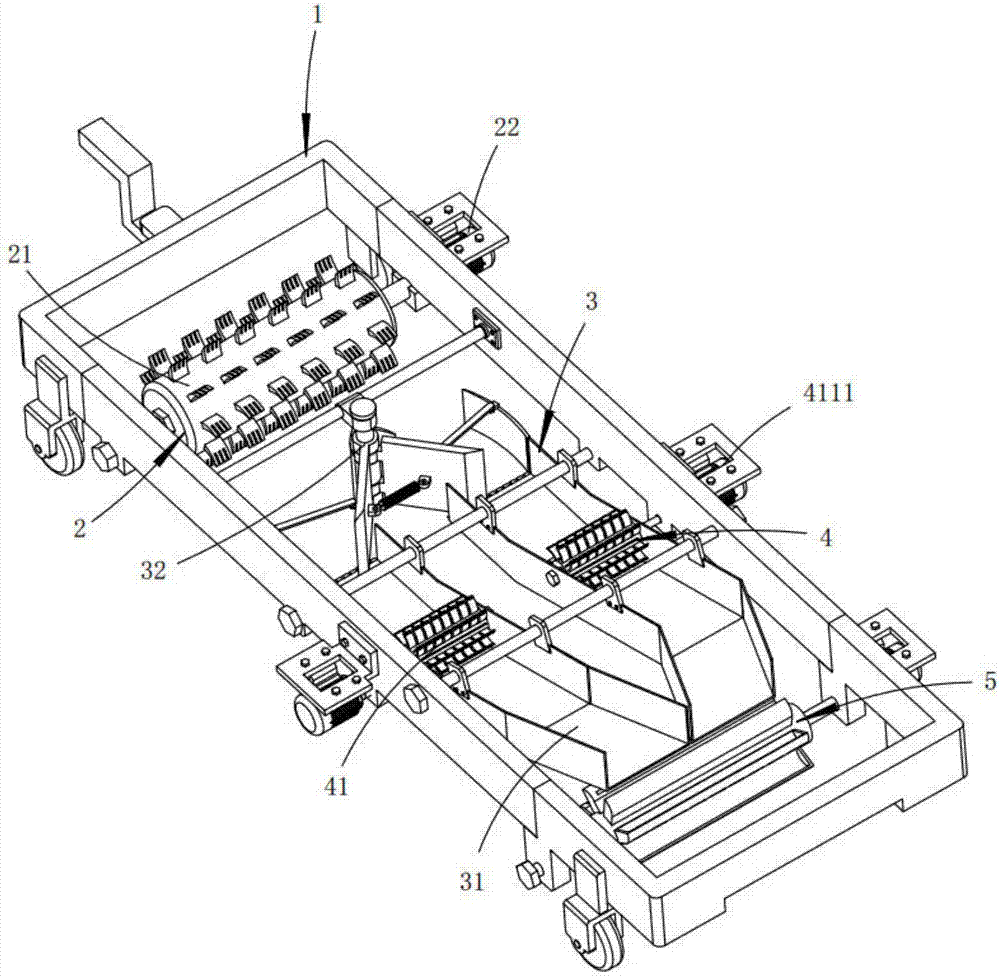

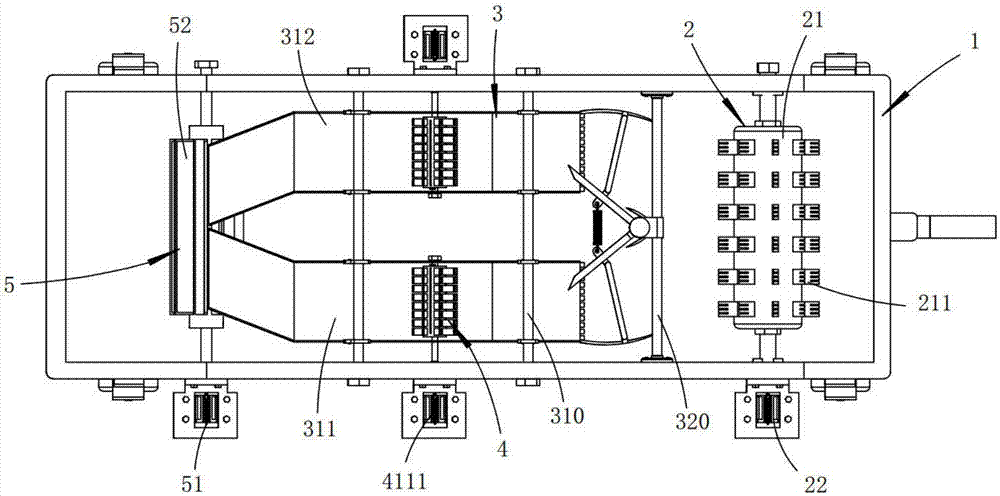

[0061] Such as figure 1 and figure 2 Shown, a kind of rotary tillage fertilization equipment, comprises walking carrier 1, also comprises:

[0062] A soil loosening device 2, which is installed at the front section of the walking carrier 1, and performs loose soil work on the land;

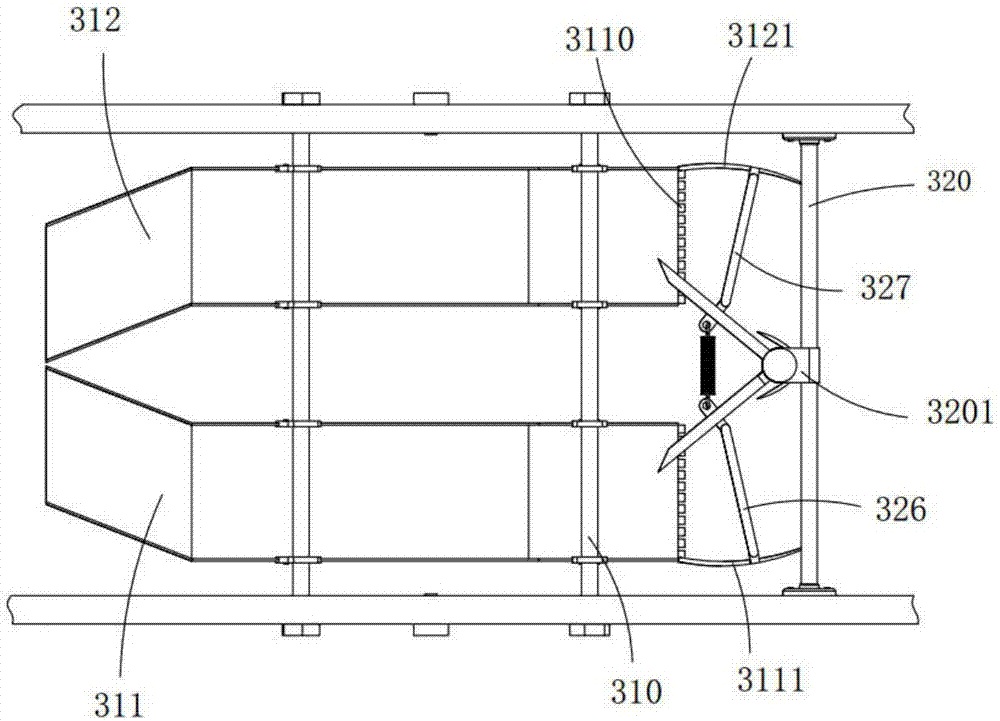

[0063] Soil transfer part 3, described soil transfer part 3 is installed on described walking carrier 1, and it is positioned at the rear of described soil loosening device 2, and it diverts the loose soil that loose soil device 2 produces to both sides and flows to post-transfer;

[0064] The fertilization part 4, the fertilization part 4 is installed on the walking carrier 1, and is located above the soil transfer part 3, which includes a soil shifting device 41 for assisting soil transfer and a soil shifting device 41 interlocked with the Fertilization device 42;

[0065] A soil covering device 5, the soil covering device 5 is installed at the rear part of the walking carrier 1, and is use...

Embodiment approach

[0067] As a preferred embodiment, the loosening device 2 includes:

[0068] The soil loosening part 21, the soil loosening part 21 is horizontally rotated and installed on the walking carrier 1, and a number of loosening rake teeth 211 are arranged around the outer peripheral surface at equal distances along the axial direction;

[0069] The first power part 22, the first power part 22 is fixedly arranged on the traveling carrier 1, and drives the soil loosening part 21 to perform soil loosening work.

[0070] What needs to be explained here is that in this embodiment, it is preferable to set the front ends of the loosening rake teeth 211 in a bifurcated shape. Through this setting, the bulkiness of the soil can be further improved when performing loosening work, which is more conducive to Subsequent fertilizer absorption.

[0071] It should be further explained that, in this embodiment, when the soil loosening member 21 rotates, its tangential movement direction with the gro...

Embodiment 2

[0097] Such as Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0098] As a preferred embodiment, the inside of the barrel body 521 is also provided with a water storage cavity 5211, and several water inlets 5212 are provided at both ends of the barrel body 521 at equal distances along the circumference. A water inlet 5213 is sleeved, and the water inlet 5213 is fixedly connected with the walking carrier 1, and a water port 5210 is opened at the upper end thereof;

[0099] A number of water outlets 5221 communicating with the water storage cavity 5211 are opened in the bottom side wall of the soil carrying member 522 along its length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com