Anti-fogging cleaning device of coal water slurry ultrasonic level gauge

A cleaning device and ultrasonic technology, applied in the field of cleaning, can solve problems such as production, equipment damage, inaccurate detection of buffer tank liquid level, etc., and achieve the effect of ensuring no damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

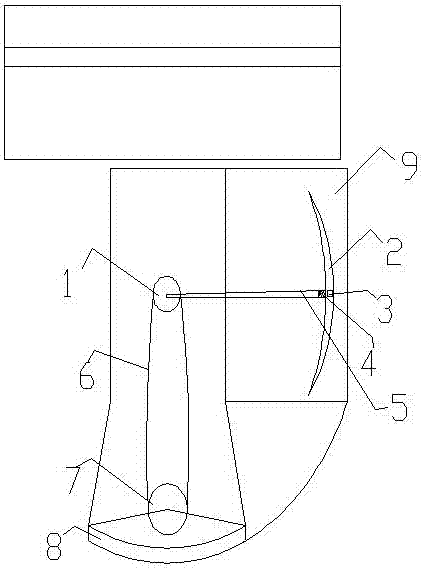

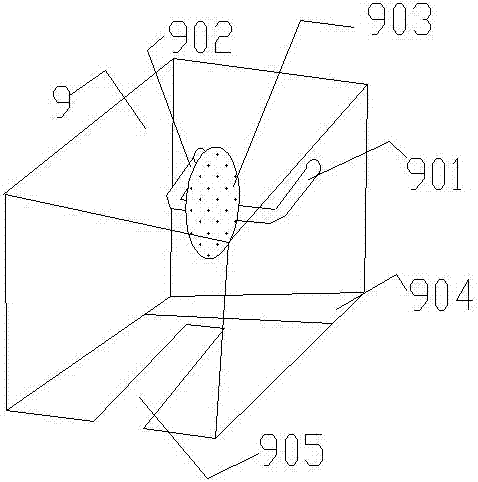

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] An anti-fogging cleaning device for a coal-water slurry ultrasonic liquid level gauge, characterized in that the cleaning device includes: a moving mechanism, a cleaning mechanism, and a sensing mechanism, and the sensing mechanism prevents the coal-water slurry ultrasonic liquid level gauge from fogging The inaccurate information is sent to the moving mechanism and the cleaning mechanism. The moving mechanism pulls out the probe lens of the coal-water slurry ultrasonic liquid level gauge through the rocker to the cleaning mechanism. The cleaning mechanism cleans the probe lens with pure water and gas drying , and then the moving mechanism moves back to the probe of the coal-water slurry ultrasonic level gauge through the rocker. The moving mechanism includes a rotator, a connecting shaft, and a limit bayonet. The rotation angle of the rotator is 90°. The reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com