Coal mining area gas extraction method

A gas extraction and mining area technology, which is applied in the technical field of coal and coalbed methane co-mining, can solve the problem of equipping the ground with too many extraction equipment, and achieve the effects of improving coal mine production connection capacity, reducing capital investment, and improving coal mine performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A gas drainage method in a coal mining area, comprising the following steps:

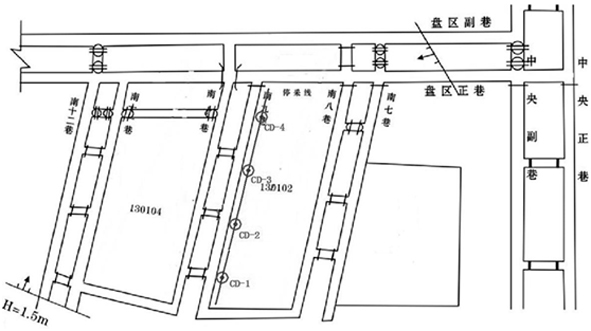

[0021] The first step is to determine the position and number of holes of the ground mining well according to the position and length of the air return lane of the coal mining face;

[0022] In the second step, the wellhead is located between the air return lane and the air inlet lane, close to the side of the air return lane, and 10m away from the air return lane, and the drilling distance between each two wellheads is 400m;

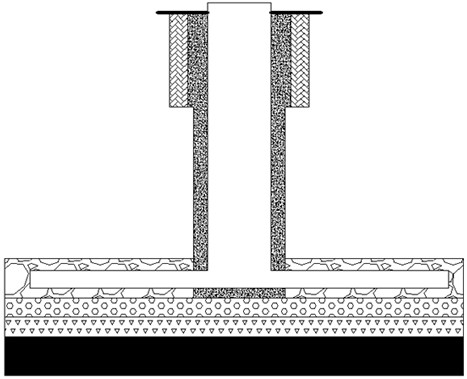

[0023] The third step is to drill the first hole to 10m below the bedrock, and put in the surface casing for cementing, and the cement will return to the ground;

[0024] The fourth step is to drill the second cut to the upper part of the main coal mining face (the specific position is determined according to the mining pressure relief height of the mine), and the technical casing is lowered to complete the second cut cementing, and the cement is returned to the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com