Tail end denitrification process device and denitrification method for Lake biogas digester

A process device and biogas digester technology, which is applied in chemical instruments and methods, climate change adaptation, water/sludge/sewage treatment, etc., can solve the problems of large resin consumption, low denitrification efficiency, and high operating costs, and improve the inferiority , expand the capacity, reduce the effect of civil works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

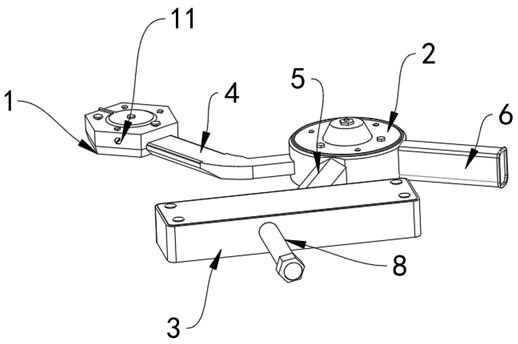

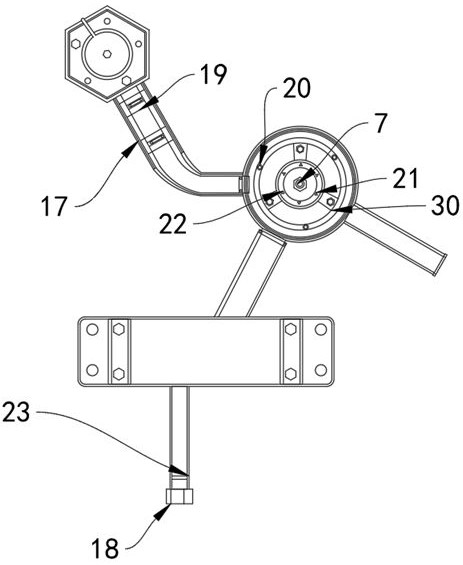

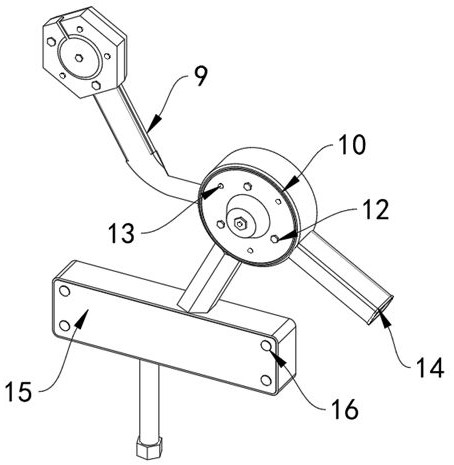

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0032] see Figure 1-5 , an embodiment provided by the present invention: a terminal denitrification process device of a covered lagoon biogas digester, comprising a covered lagoon biogas digester 1, a premixing tank 2 is installed on one side of the covered lagoon biogas digester 1, and a part of the premixed tank 2 A maturing tank 3 is arranged on the side, and an aeration device 31 is arranged at one end of the premixing tank 2, and a PLC remote controller 27 is installed at one end of the aerating device 31, and a premixing tank discharge pipe 5 is arranged at one side of the curing tank 3.

[0033] Further, a pressure gauge 11 is installed on the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com