Printer and inkjet printing method thereof

An inkjet printing and printer technology, applied in printing devices, printing, etc., can solve problems that affect the quality of printed products, cannot effectively suck ink mist and foreign objects in a timely manner, and achieve the effect of improving the quality of printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

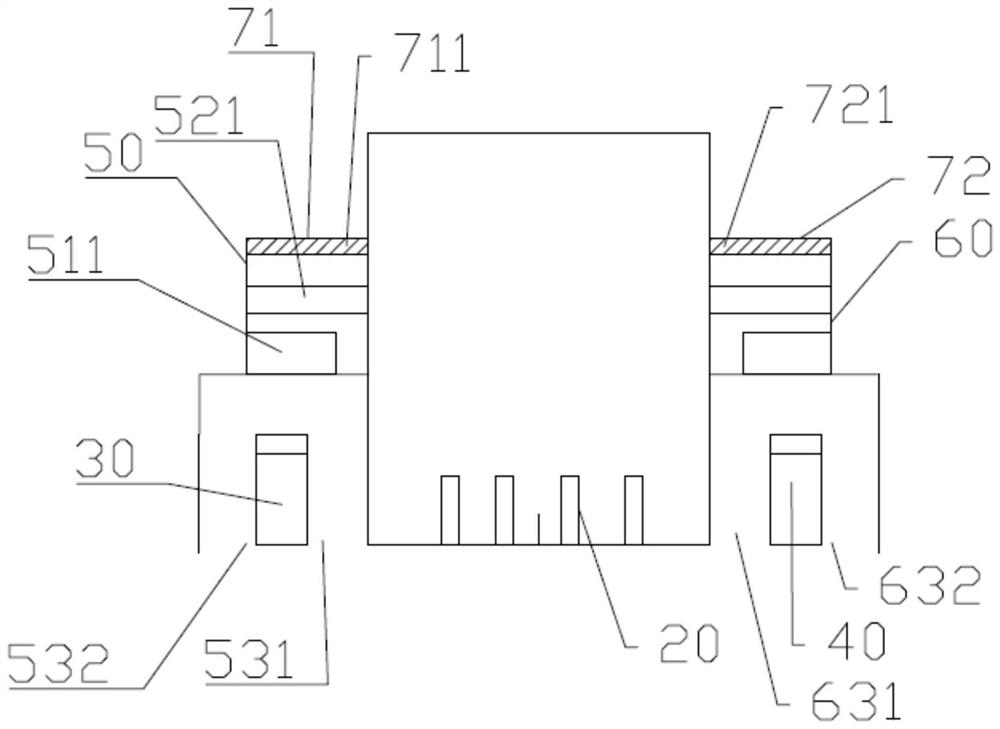

[0029] see figure 1 , the present invention discloses a printer, including a support assembly (not shown in the figure), a spray head 20, a first curing light source 30 and a first foreign matter removal assembly 50, the support assembly is used to support the printing medium to be printed, the The spray head 20 is located above the support assembly; the first foreign matter removal assembly 50 is connected to the spray head 20; the first foreign matter removal assembly 50 includes a first vent 531, a second vent 532, the first A curing light source 30 is located between the first vent 531 and the second vent 532 , and the first vent 531 is located between the first curing light 30 and the nozzle 20 . In inkjet printing, the first foreign matter removal component 50 sucks the ink mist through the first vent 531, and then the first curing light source 30 solidifies the ink. After the ink is cured, the first foreign matter removal component 50 passes through the second vent 532,...

Embodiment 2

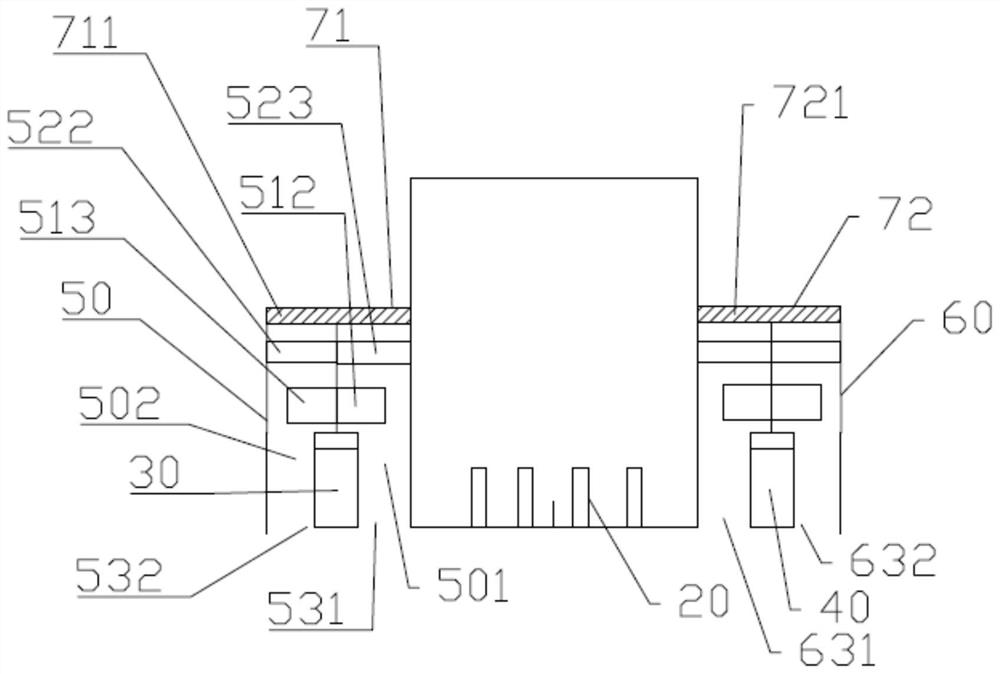

[0058] see figure 2 , the structure of this embodiment is similar to that of Embodiment 1, the difference is that: the first foreign matter removal assembly 50 also includes a first cavity 501 and a second cavity 502, and the first cavity 501 and the second cavity The bodies 502 are isolated from each other, the first vent 531 is located below the first cavity 501 , and the second vent 532 is located below the second cavity 502 . After the print head 20 prints, the first foreign matter removal assembly 50 sucks the ink mist through the first vent 531, and then the first curing light source 30 solidifies the ink on the printing medium and the ink mist in the air above the printing medium, and the air above the printing medium After the solidified ink mist forms foreign matter that floats in the air or falls on the printing medium, the first foreign matter removal assembly 50 sucks the foreign matter in the air and on the printing medium through the second vent 532 . In additi...

Embodiment 3

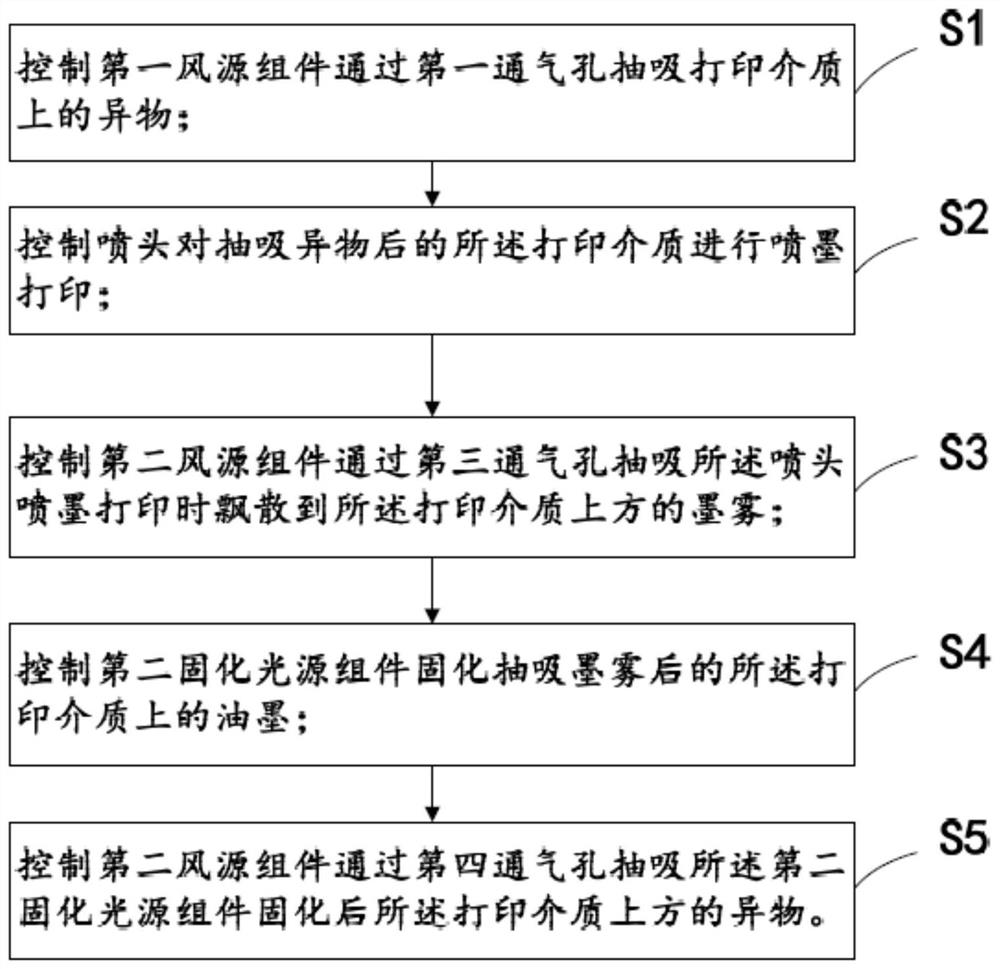

[0080] see image 3 and Figure 4 As shown, the present invention also discloses the inkjet printing method of the printer of the above-mentioned embodiment 1, which includes the following steps:

[0081] S1. Control the first foreign matter removal assembly 50 to suck the foreign matter on the printing medium through the first air hole 531;

[0082] The controller controls the force with which the first foreign object removing assembly 50 sucks foreign objects through the first ventilation hole 531 , and the suction force when sucking foreign objects is optimal so that the printing medium will not be detached from the supporting assembly.

[0083] In a preferred embodiment of the present invention, the power of the first foreign object removal assembly 50 to suck foreign objects through the first vent hole 531 is controlled by the main board of the printer.

[0084] S2. Control the nozzle 20 to perform inkjet printing on the printing medium after the foreign matter is sucke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com