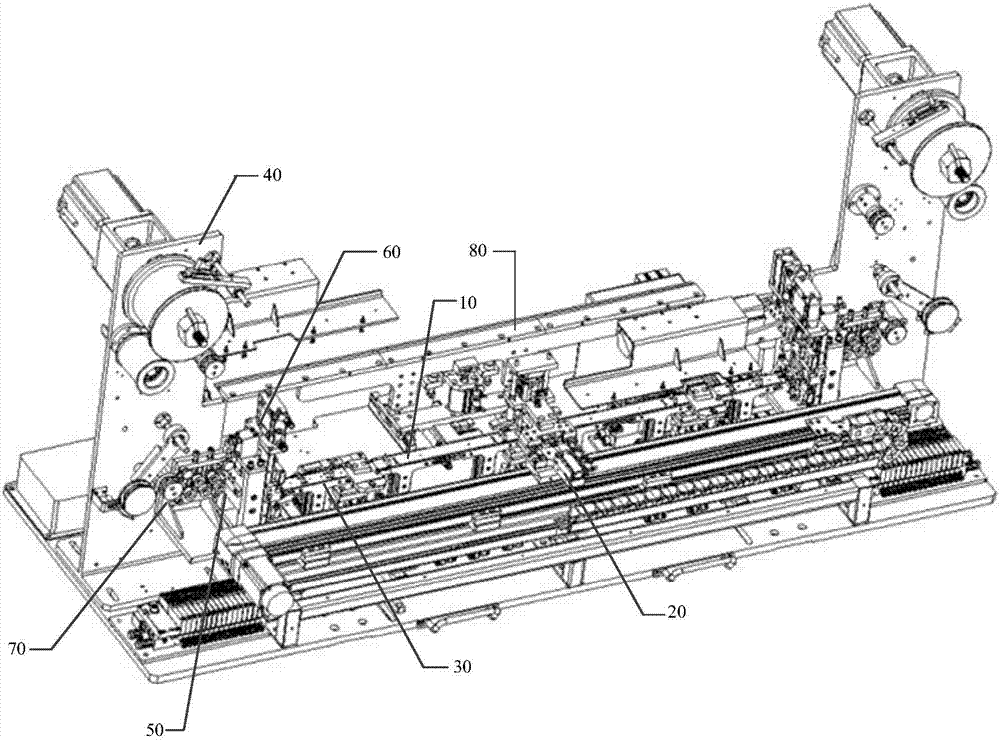

Shaping device for bus bars

A technology for shaping devices and bus bars, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve problems such as low efficiency and bus bar damage, and achieve the effect of improving the production process and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

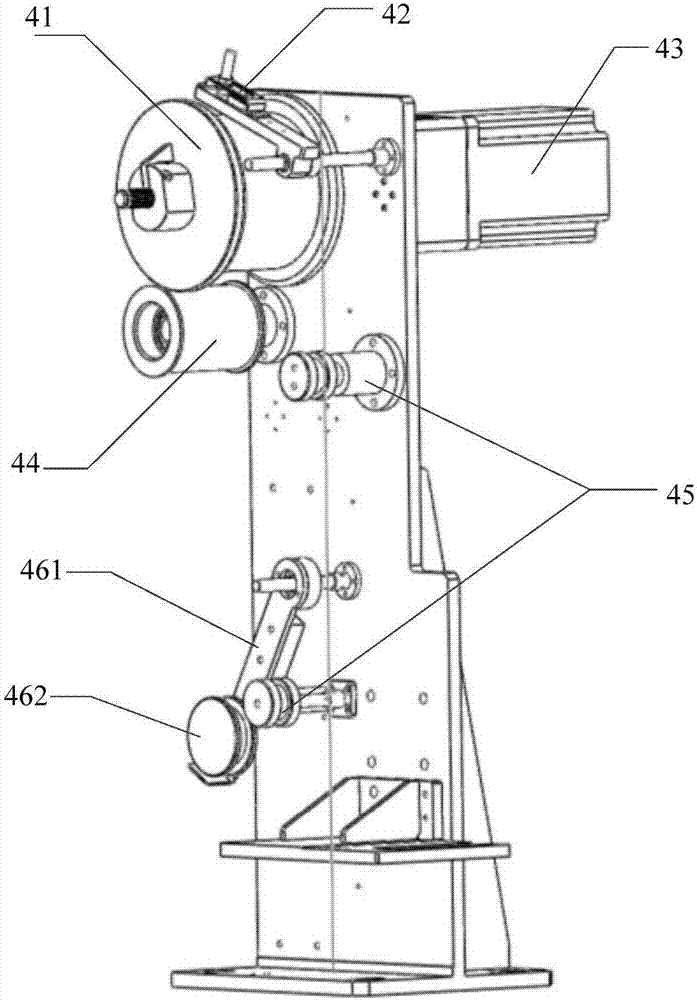

Method used

Image

Examples

Embodiment Construction

[0039] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the following exemplary examples do not represent all implementations consistent with the present invention. Rather, they are merely examples of apparatuses and methods consistent with aspects of the invention as recited in the appended claims.

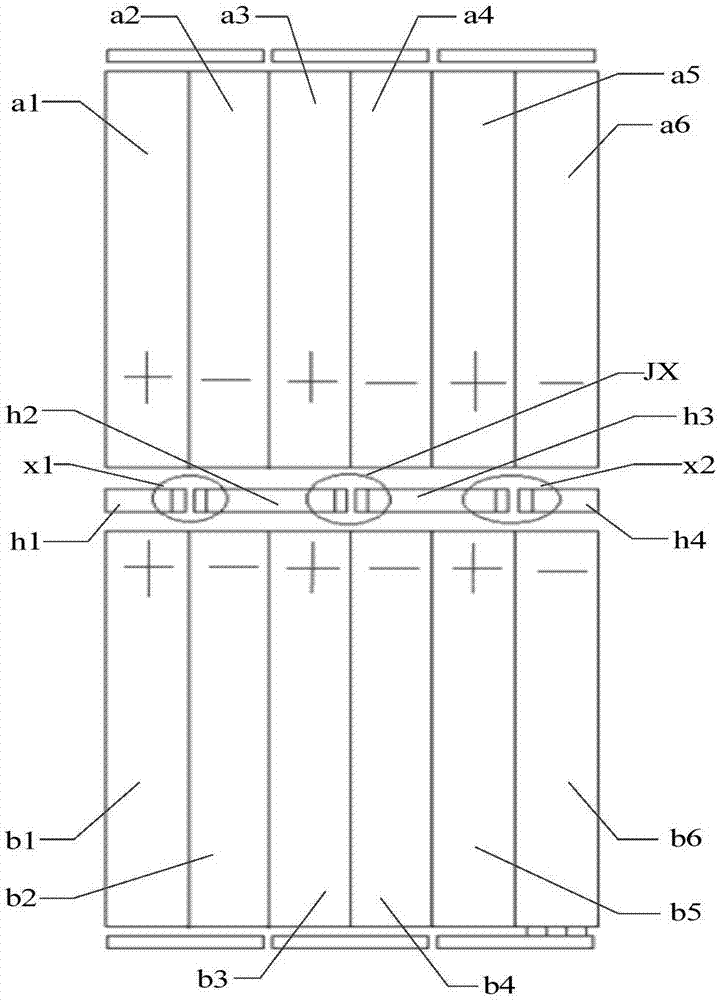

[0040]In the process of producing solar cell modules, there is a welding process of using bus bars to weld two adjacent battery strings. In this process, since the bus bars need to be connected into the junction box, the ends of the bus bars The bus bar is bent into a bulge, and the non-end area of the bus bar needs to be welded with the exposed solder strip at the end of the battery string, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com