A kind of microbial oil displacement agent and preparation method thereof

A technology for microbial oil flooding and coconut oil is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve problems such as restricting popularization and application, achieve high economic benefits, strong reliability, and improve crude oil recovery. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

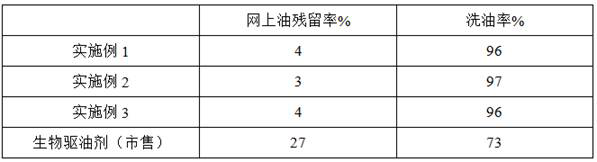

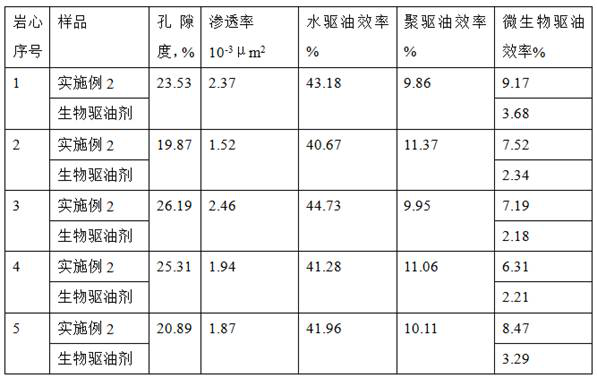

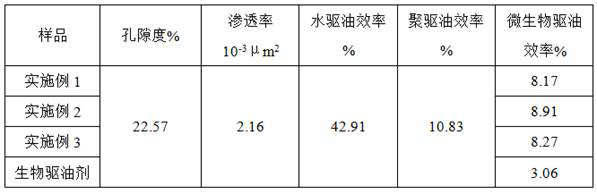

Examples

Embodiment 1

[0046] 50kg of coconut oil, 30kg of starch, NaNO 3 6kg, K 2 HPO 4 2kg, KH 2 PO 4 2.5kg, NaCl 1.5kg, MgSO 4 0.5 kg, K 2 SO 4 0.08 kg and 950 kg of deionized water were placed in a fermenter, the temperature was raised to 33 °C and continuously stirred, the pH of the solution was adjusted to 7.2 with a 3% NaOH solution by mass, and the solution was sterilized at 115 °C for 20 min.

[0047] Cool to 28°C, add 10kg of Bacillus amyloliquefaciens bacterial liquid to the fermenter, then add 80kg of lauryl aminopropionic acid, and ferment at constant temperature for 7 days. That is, the desired microbial oil-displacing agent is obtained.

Embodiment 2

[0049] 60kg of coconut oil, 40kg of starch, NaNO 3 7kg, K 2 HPO 4 2.3kg, KH 2 PO 4 2.0kg, NaCl 1.3kg, MgSO 4 0.4kg, K 2 SO 4 0.06kg and 900kg of deionized water were placed in a fermenter, heated to 40°C and continuously stirred, the pH of the solution was adjusted to 7.2 with 3% NaOH solution by mass, and sterilized at 115°C for 20min.

[0050] Cool to 40° C., add 20 kg of Bacillus amyloliquefaciens bacterial liquid to the fermentation tank, add 90 kg of lauryl aminopropionic acid, and ferment at constant temperature for 6 days. That is, the desired microbial oil-displacing agent is obtained.

Embodiment 3

[0052] 80kg of coconut oil, 50kg of starch, NaNO 3 8kg, K 2 HPO 4 2.5kg, KH 2 PO 4 1.5kg, NaCl 1kg, MgSO 4 0.3kg, K 2 SO 4 0.05kg and 800kg of deionized water were placed in a fermenter, heated to 55°C and continuously stirred, the pH of the solution was adjusted to 7.2 with 3% NaOH solution by mass, and sterilized at 115°C for 20min.

[0053] Cool to 55°C, add 40kg of Bacillus amyloliquefaciens bacterial liquid to the fermentation tank, then add 100kg of lauryl aminopropionic acid, and ferment at constant temperature for 5 days. That is, the desired microbial oil-displacing agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com