Testing device for universal circuit breaker

A testing device and circuit breaker technology, applied in circuit breaker testing and other directions, can solve problems such as wiring errors, waste, and low production efficiency, and achieve the effects of ensuring stability, simple operation, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

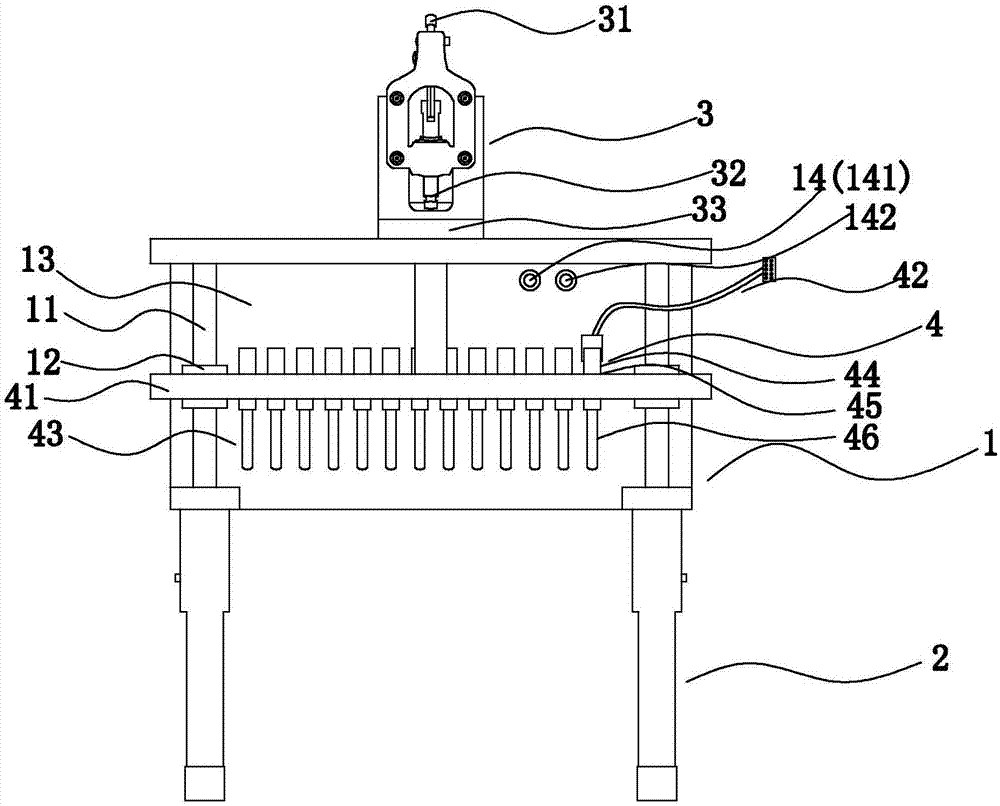

[0048] Refer to attached Figure 1-7 As shown, a test device for a universal circuit breaker includes a main body 1 on which a fixing mechanism 2 , a driving mechanism 3 and an operating mechanism 4 are arranged.

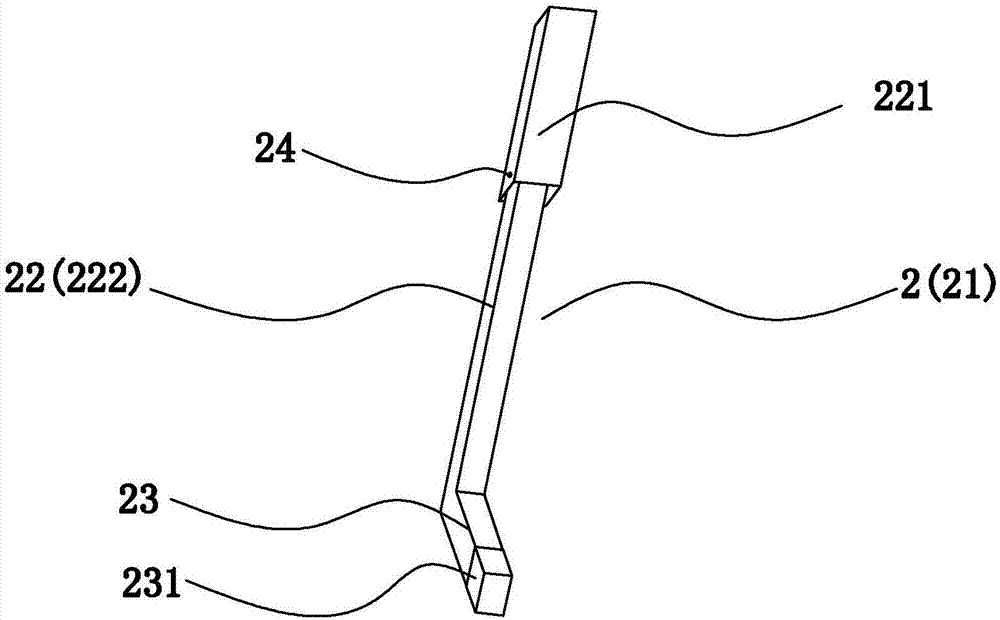

[0049] The fixing mechanism 2 includes a fixing bracket 21. The fixing bracket 21 includes a telescopic piece 22, a fixing part 23 and a fixing piece 24. The telescopic piece 22 includes a connecting pipe I 221 and a connecting pipe II 222. The connecting pipe I 221 is connected to the main body 1, and the connecting pipe II 222 is connected to the fixing part. 23 connection, the connecting pipe II 222 and the fixed part 23 have a "7-shaped" structure, so that the fixed part 23 is closely attached to the universal circuit breaker housing; For fixing, the connecting pipe I221 and the connecting pipe II222 can also be engaged by clamping. The connecting pipe II222 is provided with elastic protrusions, and the connecting pipe I221 is provided with adjustment through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com