A method for controlling a food processing machine

A technology of food processing machine and control method, which is applied in the direction of kitchen utensils, spill prevention, household utensils, etc., and can solve the problems of long pulping time, low pulp temperature, poor pulverization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

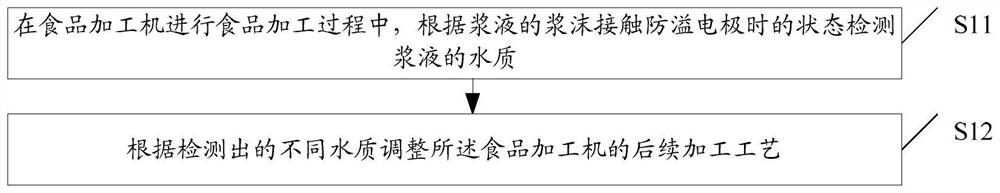

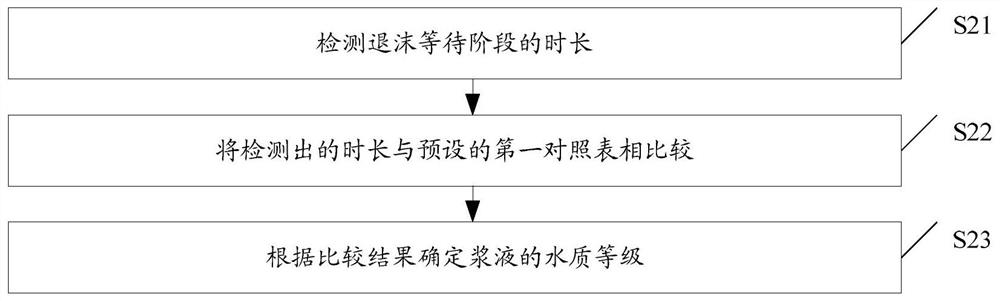

[0052] A method of controlling a food processor comprising an anti-spill electrode such as figure 1 As shown, the method includes S11-S12:

[0053] S11. During the food processing process of the food processing machine, the water quality of the slurry is detected according to the state when the slurry of the slurry touches the anti-overflow electrode.

[0054] In the embodiment of the present invention, it is tested that the water quality with high TDS (Total Dissolved Solids) value has high foam during the pulping process, and the foam is not easy to eliminate. In view of this situation, the common solution at present is to increase the waiting time in the pulping room. This time is often measured according to a large number of experiments, and generally takes a long time, resulting in a longer total pulping cycle. In addition, in most cases, it is only a certain water quality that is difficult to eliminate the foam during the pulping process. If the anti-overflow strategy is ...

Embodiment 2

[0105] On the basis of the first embodiment, this embodiment provides several specific examples of process adjustment according to water quality.

[0106] In the embodiment of the present invention, with regard to the adjustment scheme in the first embodiment, different adjustment strategies can be set according to different food processing stages, and the specific embodiments are taken as examples below to illustrate.

[0107] In the embodiment of the present invention, the whole food processing process can be divided into the following food processing stages in turn: preheating stage (stage 1), preliminary crushing+interval waiting stage (stage 2), formal heating+collision anti-overflow stage (stage 3), defoaming waiting stage (stage 4), concentrated crushing stage (stage 5), boiling stage (stage 6). The adjustment strategies for the follow-up process are described below for different water quality testing stages:

[0108] Situation 1. When the water quality is detected by ...

Embodiment 3

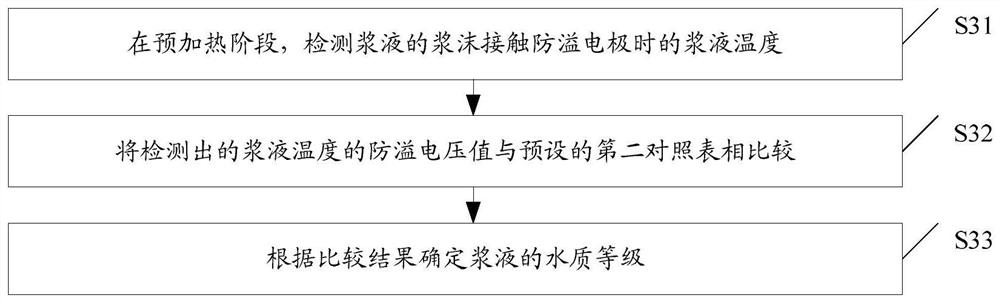

[0156] In this embodiment, on the basis of the above-mentioned embodiment 1 or embodiment 2, the boiling points at different altitudes are compensated.

[0157] Optionally, the method further includes: adjusting the boiling point at the current altitude according to the boiling point at zero altitude; that is, adjusting the preheating and anti-overflow temperature point according to the altitude temperature to eliminate the influence of altitude on the detected temperature.

[0158] In the embodiment of the present invention, the same water has different boiling points at different altitudes, so when detecting the temperature of the anti-overflow in the pre-heating stage, there will be deviations in the measured temperature value due to different altitudes in different regions. In this embodiment, after taking into account the influence of altitude on the boiling point of water, the influence of different altitudes on the boiling point of water is eliminated, and whether the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com