Automatically-alarming cable bridge machining method

A technology of cable bridge and processing method, which is applied in the direction of electrical components, etc., can solve the problems of high cost, achieve the effect of reducing processing cost and the structure of the finished product is simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

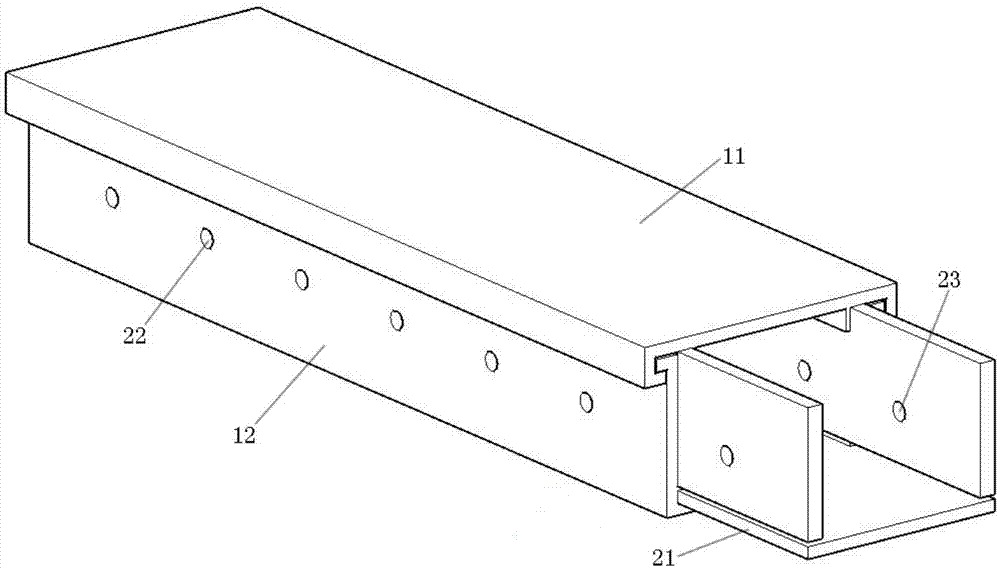

[0020] a structure such as figure 1 The processing method of the shown automatic alarm cable tray; proceed in the following steps:

[0021] ①External opening: Open the outer hole 22 on the two sides of the bottom groove 12 of the cable tray;

[0022] ②Insertion: Insert the fire barrier 21 into the inner wall of the bottom groove 12;

[0023] ③ Inner opening: at the position corresponding to the outer hole 22, drill holes inward, and punch the inner hole 23 on the fireproof partition 21;

[0024] ④Insertion: Insert the temperature sensor or temperature sensitive switch from the outer hole 22 into the inner hole 23 .

[0025] The outer holes 22 are multiple on each side plate of the bottom tank 12 .

[0026] The outer holes 22 are distributed in a straight line.

[0027] The outer holes 22 are uniformly distributed along a strai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap