Pneumatic jaw clutch

A pneumatic clutch and claw-type technology, which is applied to fluid-driven clutches, clutches, non-mechanical-driven clutches, etc., can solve the problems of poor maintainability and complex structure, and achieve the effect of small size, compact structure and reliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

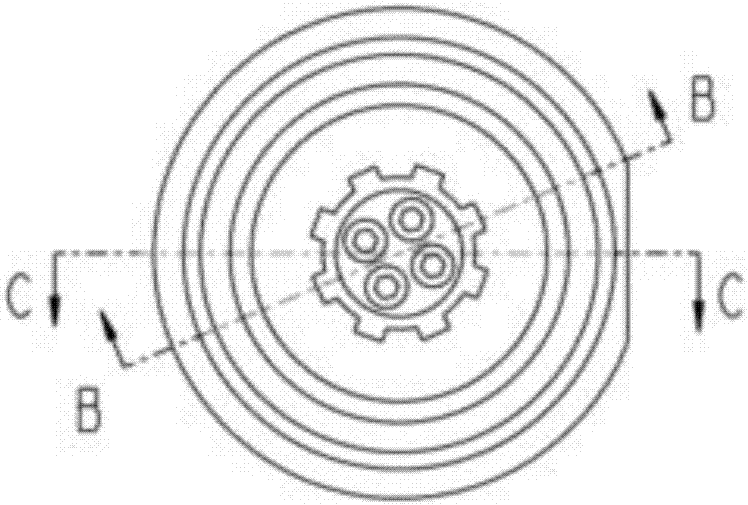

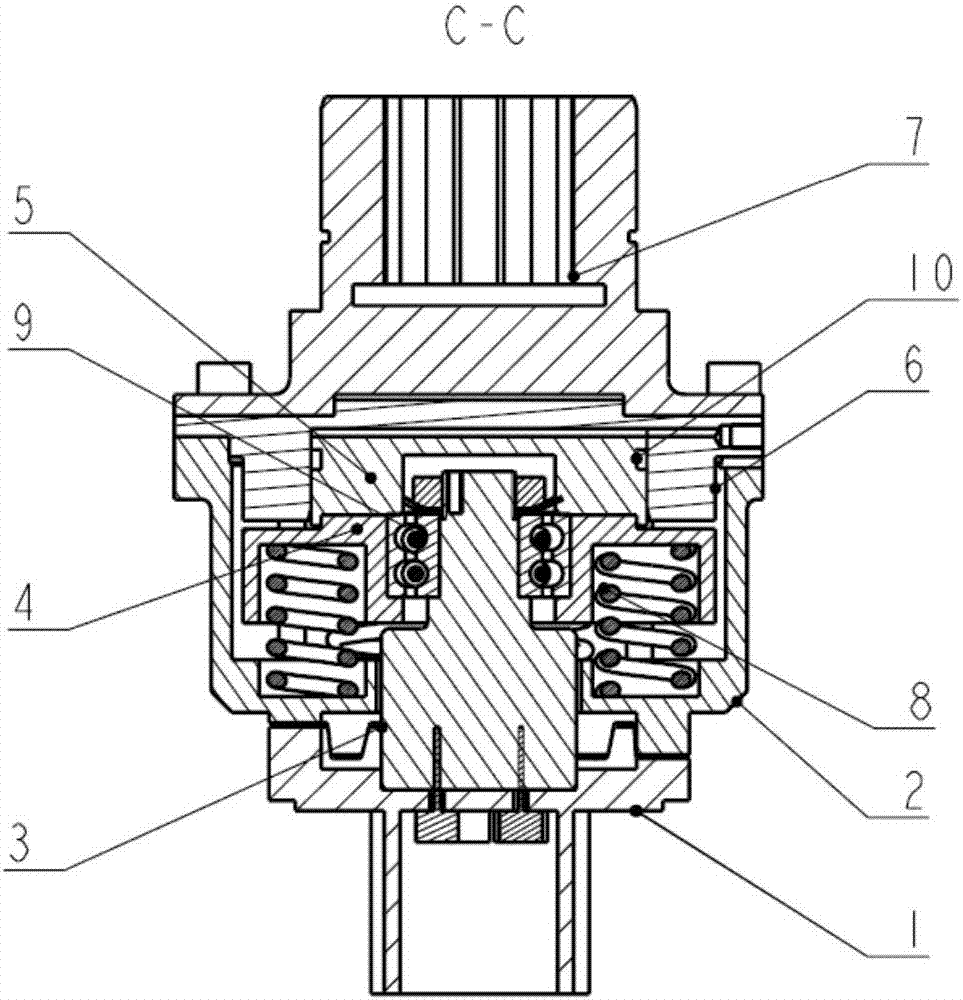

[0027] The jaw type pneumatic clutch provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

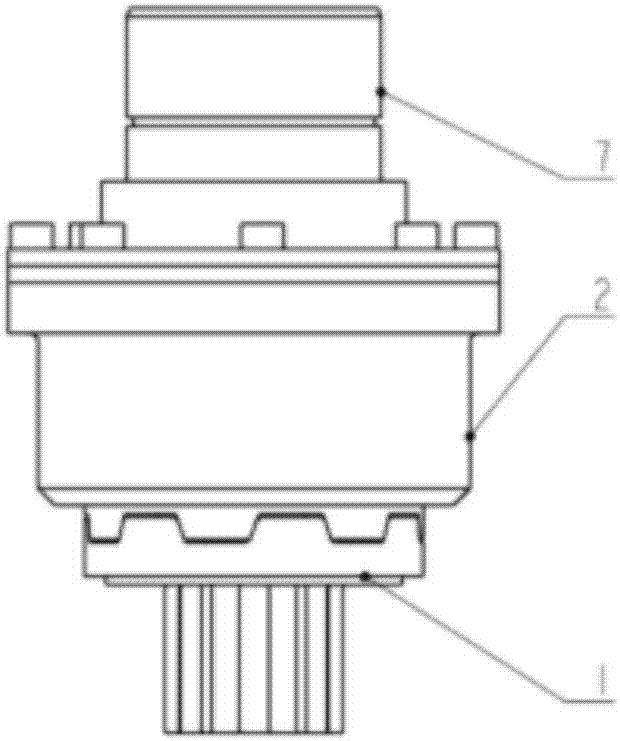

[0028] Such as Figure 1-4 As shown, a jaw type pneumatic clutch includes left half clutch 1, right half clutch 2, rotating shaft 3, spring seat 4, piston 5, cylinder 6, output shaft 7, preload spring 8, double row angular contact bearing 9 , O-ring 10, adjusting screw 11, spring washer 12, anti-rotation screw 13, fastening screw 14, spring washer 2 15, stop washer 16, lock nut 17, fastening screw 2 18;

[0029] Among them: the left half clutch part includes left half clutch 1, rotating shaft 3, double row angular contact ball bearing 9, lock nut 17, brake washer 16, spring seat 4 and piston 5, and the parts are fixedly connected by fastening screws 14;

[0030] The right half clutch part includes the right half clutch 2, the cylinder 6 and the output shaft 7, and the parts are fixedly connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap