Switching tool for different types of double-joint bearing chuck

A kind of joint bearing and double joint technology, which is applied in the testing of measuring devices, instruments, mechanical parts, etc., can solve the problems of increasing operator mistakes, heavy chuck weight, etc., and achieves convenient operation, improved efficiency, and high clamping accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

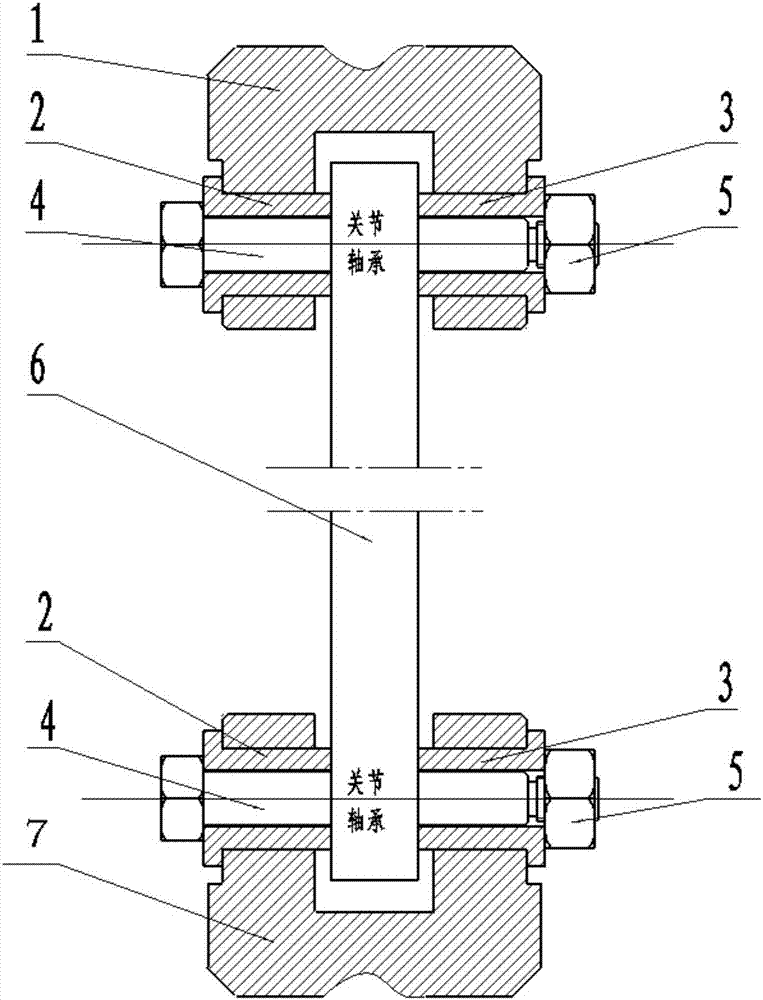

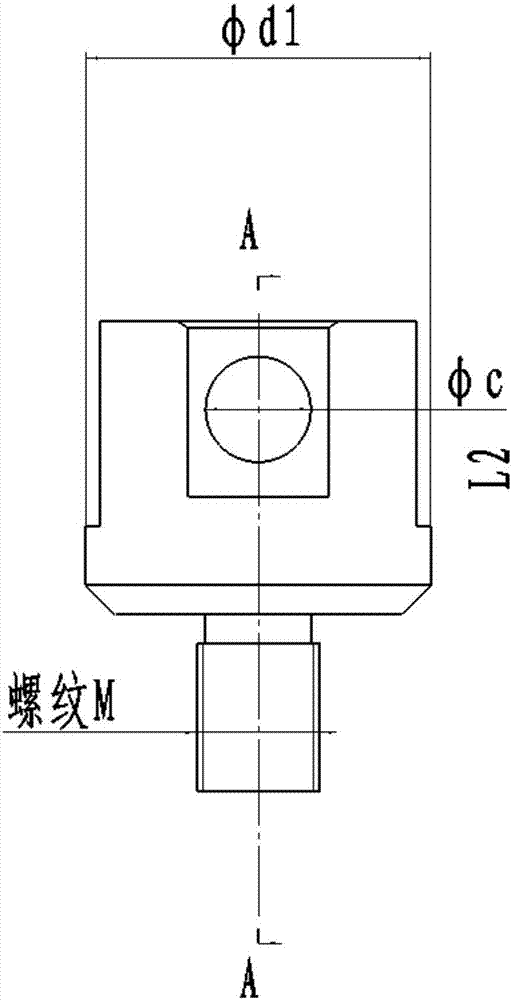

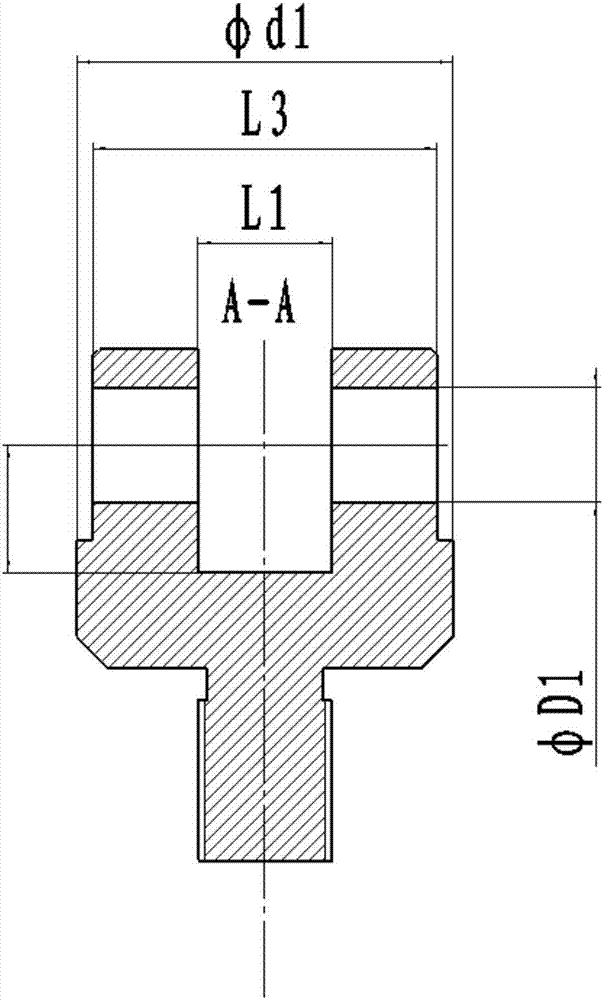

[0014] refer to Figure 1-Figure 3 . In the embodiments described below, a different type of double joint bearing chuck switching tool includes a fixing mechanism connected to a test bench. The fixing mechanism is divided into an upper chuck 1 and a lower chuck 7, the upper chuck 1 and the lower chuck 7 are symmetrical and do not replace modules; both the upper chuck 1 and the lower chuck 7 have only cross holes, and the tested The joint bearings at both ends of the device 6 are concentrically connected between the upper chuck 1 and the lower chuck 7 through the left center shaft sleeve as a replaceable module, and the inner hole of the joint bearing is inserted into the transverse through hole of the upper chuck 1 and the lower chuck 7 The spindle 4 of the upper left spindle sleeve and the right spindle sleeve 3 is screwed into the screw thread of the spindle 4 by the spindle supporting nut 5 and fixed; When the joint bearings at the end of the booster under test are differ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap