Die-opening method and driving system for spring die of two-plate injection molding machine

A spring mold and drive system technology, which is applied in the field of mold opening method and drive system of the spring mold of a two-platen injection molding machine, can solve problems such as affecting the quality of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

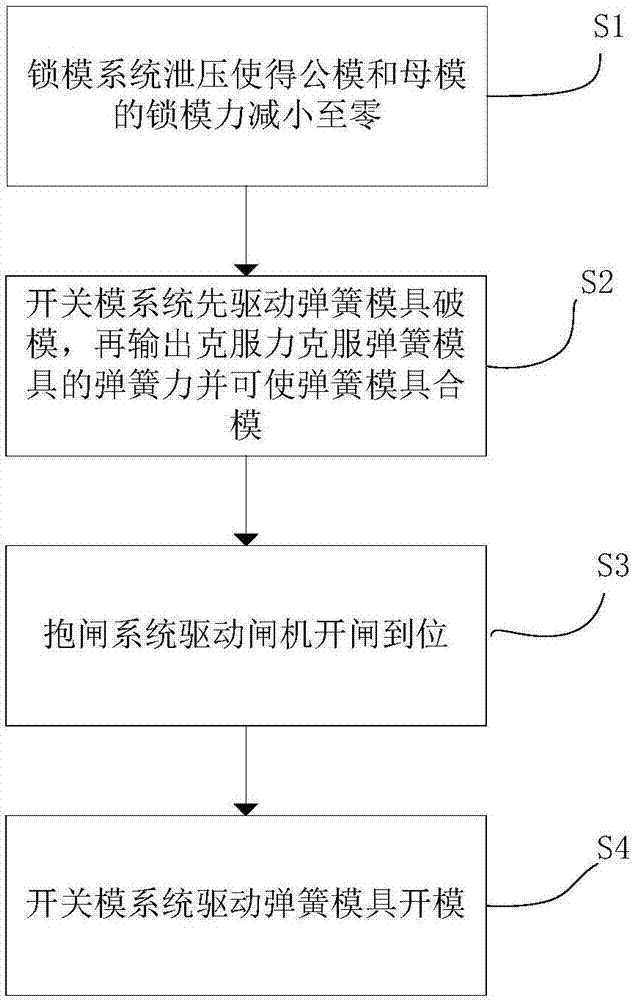

[0033] Please refer to Figure 1-Figure 4 , the mold opening method of the spring mold of the two-plate injection molding machine, which comprises the steps of:

[0034] S1, the clamping system 100 releases the pressure so that the clamping force of the male mold 520 and the female mold 530 is reduced to zero;

[0035] S2, the switch mold system 200 first drives the spring mold 500 to break the mold, and then outputs an overcoming force to overcome the spring force of the spring mold 500 and close the spring mold 500;

[0036] S3, the brake system 300 drives the brake machine 400 to open the brake;

[0037] S4, the switch mold system 200 drives the spring mold 500 to open the mold.

[0038] Specifically, after the clamping system 100 releases the pressure, the spring mold 500 has no clamping force, and the switch mold system 200 drives the spring mold 500 to break the mold. After the mold break is completed, the switch mold system 200 outputs an overcoming force to overcome ...

Embodiment 2

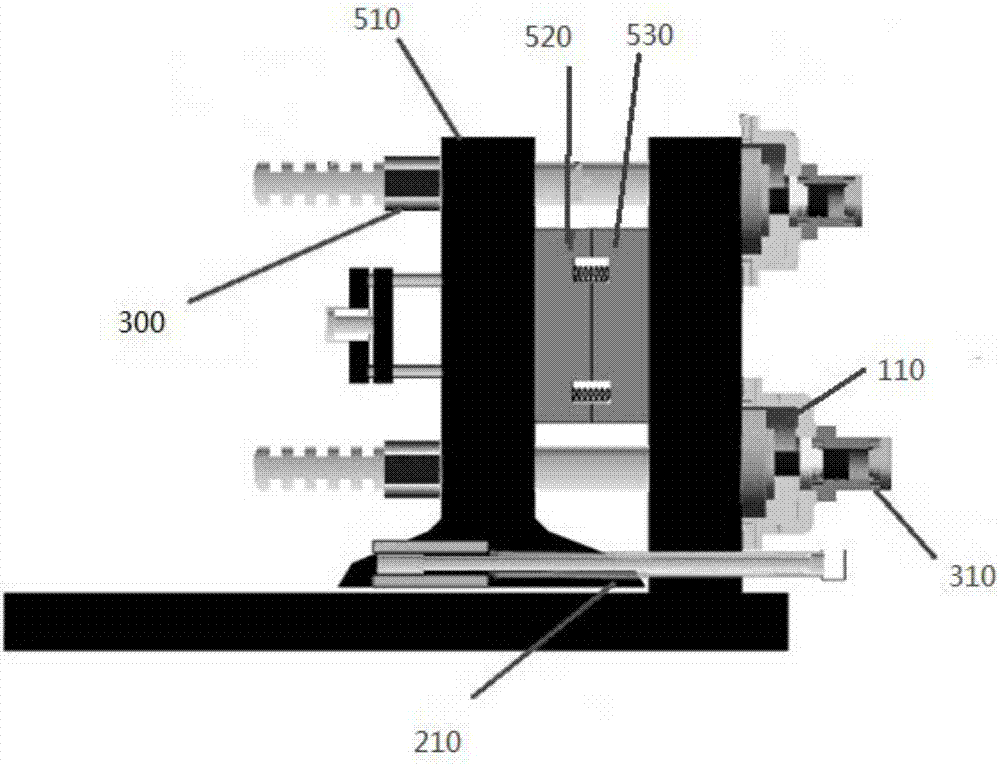

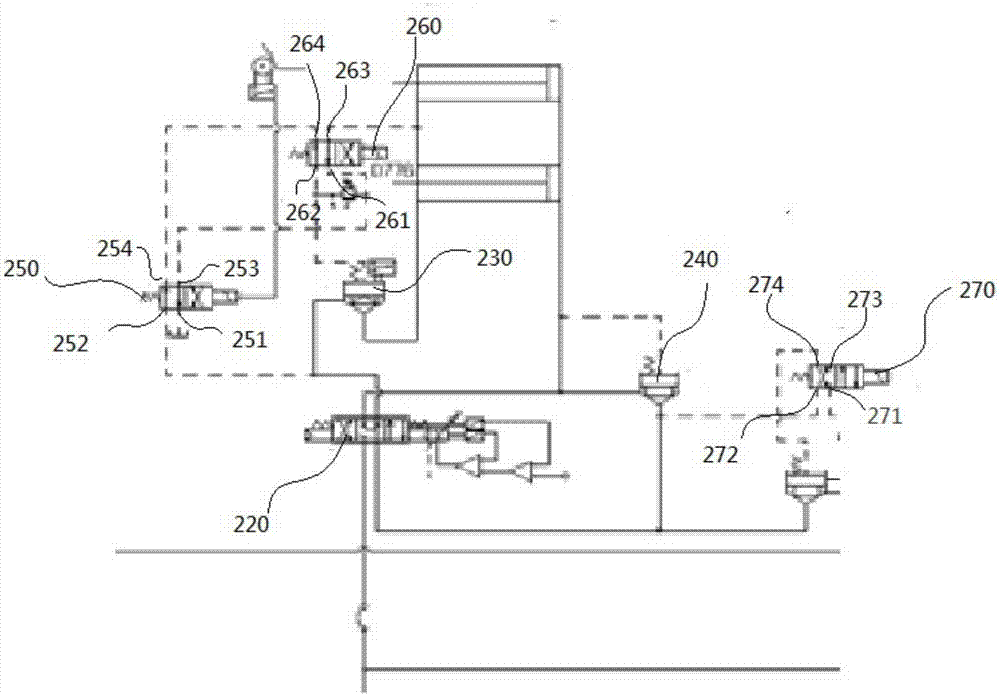

[0049] Such as Figure 1-Figure 4 , the driving system of the spring mold of the two-platen injection molding machine, including:

[0050] The mold clamping system 100 is used to provide mold clamping force for the male mold 520 and the female mold 530;

[0051] The switch mold system 200 is used to drive the spring mold 500 to break the mold, output the overcoming force to overcome the spring force of the spring mold 500 to make the spring mold 500 close the mold; the switch mold system 200 is also used to drive the spring mold 500 to open and close the mold;

[0052] The brake system 300 is used to drive the brake 400 to lock and open the brake. Before the mold is opened, the brake is in the brake state, and the brake 400 is used to lock the spring mold 500 in the mold closing state.

[0053] In this embodiment, the operation sequence of the mold locking system 100 , the mold opening and closing system 200 , and the brake system 300 can be controlled by PLC.

[0054] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com