A method for press-fitting a gun frame balancer

A technology of balancer and gun holder, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of poor assembly quality, cumbersome operation, low assembly efficiency, etc., to reduce tooling, simple operation, and improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

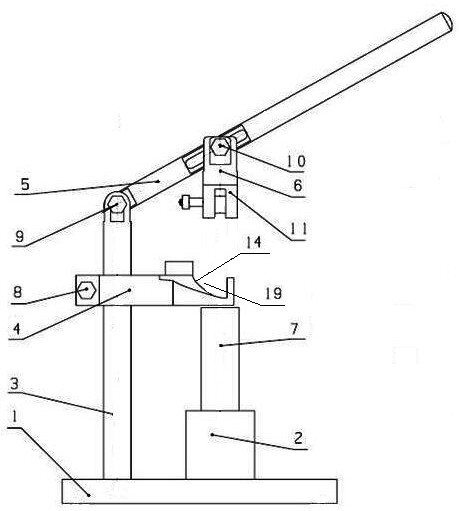

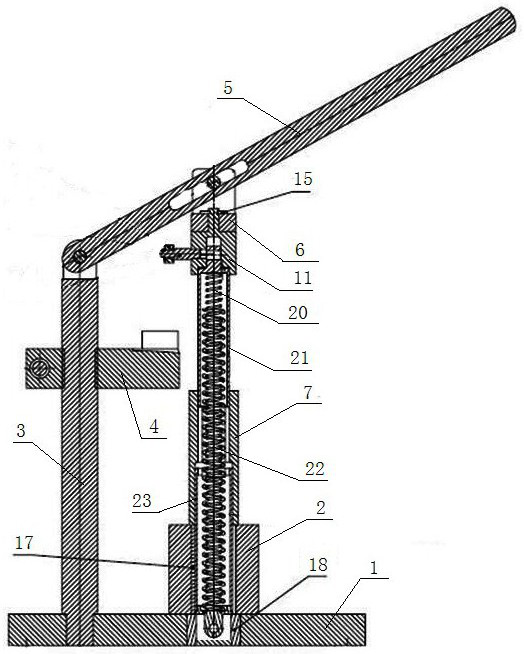

[0037] see Figure 1-Figure 3 , a method for press-fitting a gun frame balancer, comprising the following steps:

[0038] a. First put the balancer outer tube 23 into the outer tube fixing seat 2 of the gun frame balancer press-fitting machine, tighten the set screws, and then put the inner balance spring 20 and balance spring 22 into the inner hole of the balancer outer tube 23 , then insert the guide tube 7 into the balancer outer tube 23;

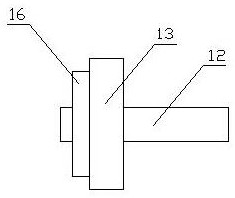

[0039] b. Then put the inner tube 21 of the balancer into the guide cylinder 7, put on the inner balance spring 20 and the balance spring 22, put the inner tube sleeve 11 on the upper end of the inner tube 21 of the balancer, adjust the direction of the roller shaft 12, press down and The pressure rod 5 connected to the inner sleeve 11, the inner sleeve 11 drives the inner tube 21 of the balancer to move axially in the guide cylinder 7;

[0040] c. Continue to press down the inner sleeve 11. When the roller 13 on the inner sleeve 11 re...

Embodiment 2

[0044] see Figure 1-Figure 3 , a method for press-fitting a gun frame balancer, comprising the following steps:

[0045] a. First put the balancer outer tube 23 into the outer tube fixing seat 2 of the gun frame balancer press-fitting machine, tighten the set screws, and then put the inner balance spring 20 and balance spring 22 into the inner hole of the balancer outer tube 23 , then insert the guide tube 7 into the balancer outer tube 23;

[0046] b. Then put the inner tube 21 of the balancer into the guide cylinder 7, put on the inner balance spring 20 and the balance spring 22, put the inner tube sleeve 11 on the upper end of the inner tube 21 of the balancer, adjust the direction of the roller shaft 12, press down and The pressure rod 5 connected to the inner sleeve 11, the inner sleeve 11 drives the inner tube 21 of the balancer to move axially in the guide cylinder 7;

[0047] c. Continue to press down the inner sleeve 11. When the roller 13 on the inner sleeve 11 re...

Embodiment 3

[0052] see Figure 1-Figure 3 , a method for press-fitting a gun frame balancer, comprising the following steps:

[0053] a. First put the balancer outer tube 23 into the outer tube fixing seat 2 of the gun frame balancer press-fitting machine, tighten the set screws, and then put the inner balance spring 20 and balance spring 22 into the inner hole of the balancer outer tube 23 , then insert the guide tube 7 into the balancer outer tube 23;

[0054] b. Then put the inner tube 21 of the balancer into the guide cylinder 7, put on the inner balance spring 20 and the balance spring 22, put the inner tube sleeve 11 on the upper end of the inner tube 21 of the balancer, adjust the direction of the roller shaft 12, press down and The pressure rod 5 connected to the inner sleeve 11, the inner sleeve 11 drives the inner tube 21 of the balancer to move axially in the guide cylinder 7;

[0055] c. Continue to press down the inner sleeve 11. When the roller 13 on the inner sleeve 11 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com