Wire harness fixing support

A wire harness fixing and support rod technology, which is applied in the direction of electric circuits or fluid pipelines, transportation and packaging, vehicle parts, etc., can solve the problems of potential safety hazards, thick wire harnesses, and poor bending of wire harnesses, so as to avoid contact wear and protect wire harnesses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

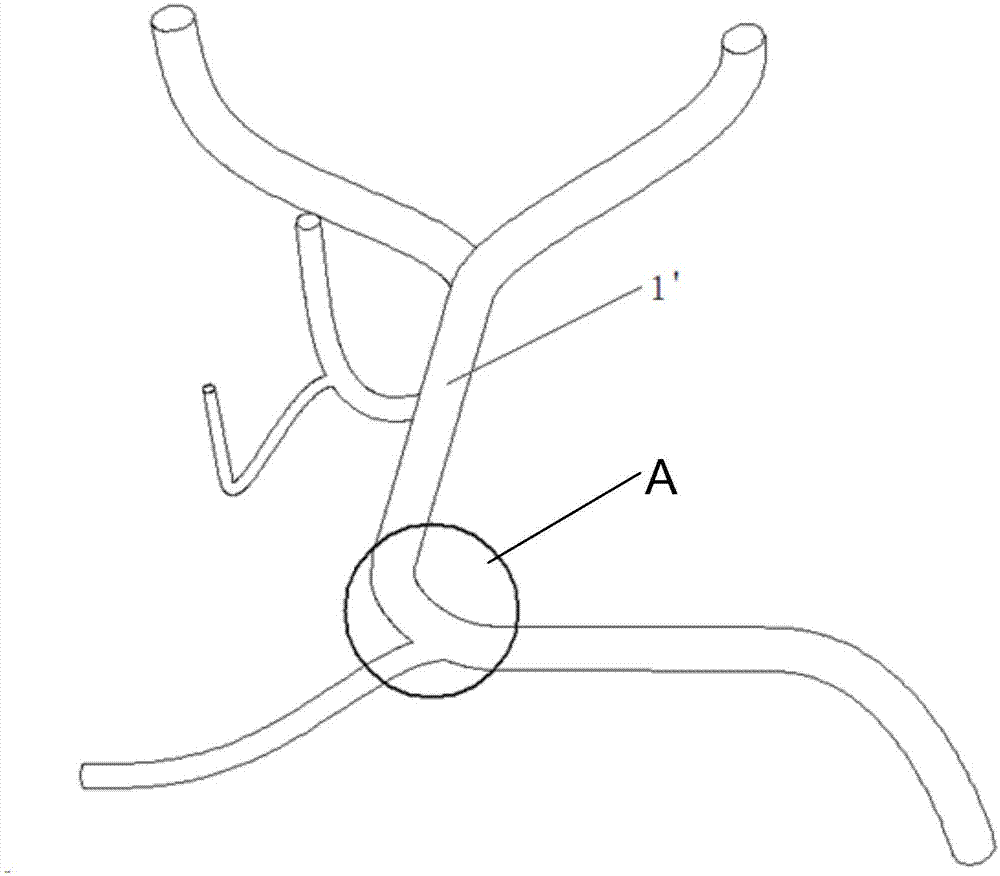

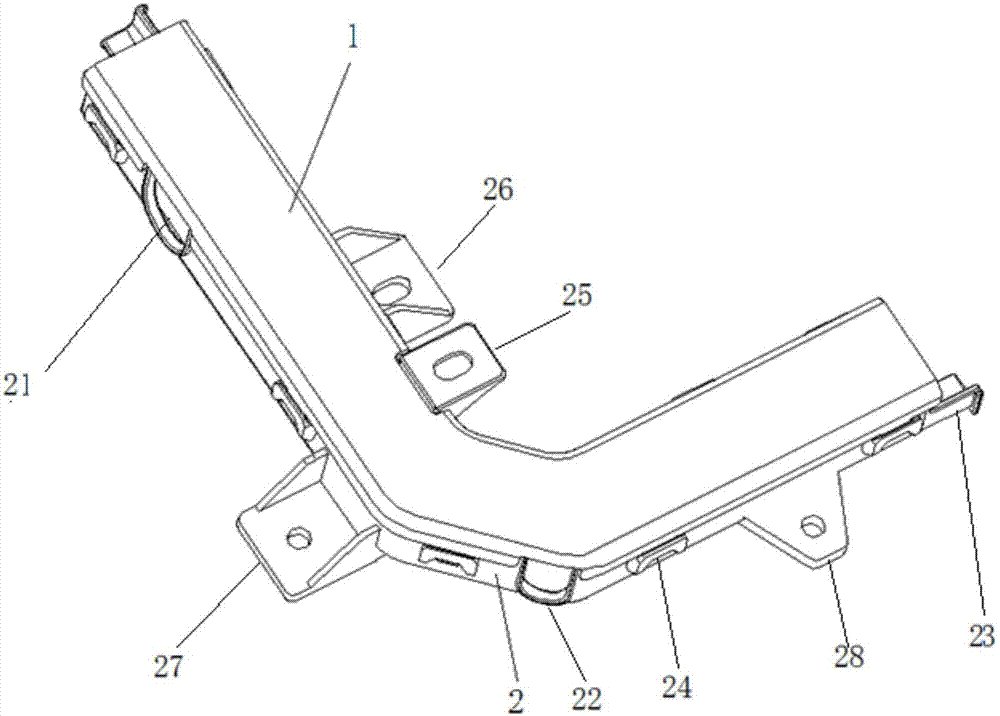

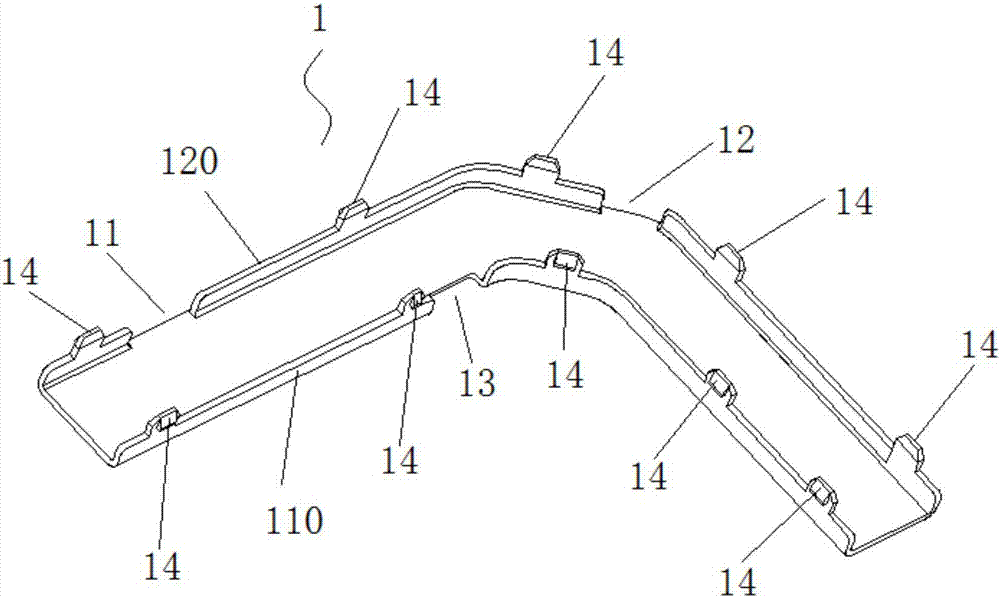

[0041] The embodiment of the present invention provides a wire harness fixing bracket, wherein: Please refer to figure 2 , image 3 and Figure 6 As shown, the wire harness fixing bracket includes an upper cover plate 1 and a lower cover plate 2; both the upper cover plate 1 and the lower cover plate 2 are bent plates; the two opposite edges of the upper cover plate 1 are Both are provided with upper vertical arms, and the two upper vertical arms are arranged perpendicular to the upper cover plate 1; the two upper vertical arms are located on the same side of the upper cover plate 1 and are arranged oppositely; the lower cover plate 2 The two opposite edges are provided with lower vertical arms, and the two lower vertical arms are arranged vertically to the lower cover plate 2; the two low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com