High-pressure one-way valve suitable for high-pressure plunger pump of cleaning machine

A technology of high-pressure plunger pumps and high-pressure check valves, which is applied to components, pump components, and mechanical equipment of pumping devices for elastic fluids, and can solve the problem of inability to guarantee the sealing performance of valve seats and reduce the service life of check valves , valve or pump volumetric efficiency reduction and other issues, to reduce the probability of contact wear, avoid contact wear and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

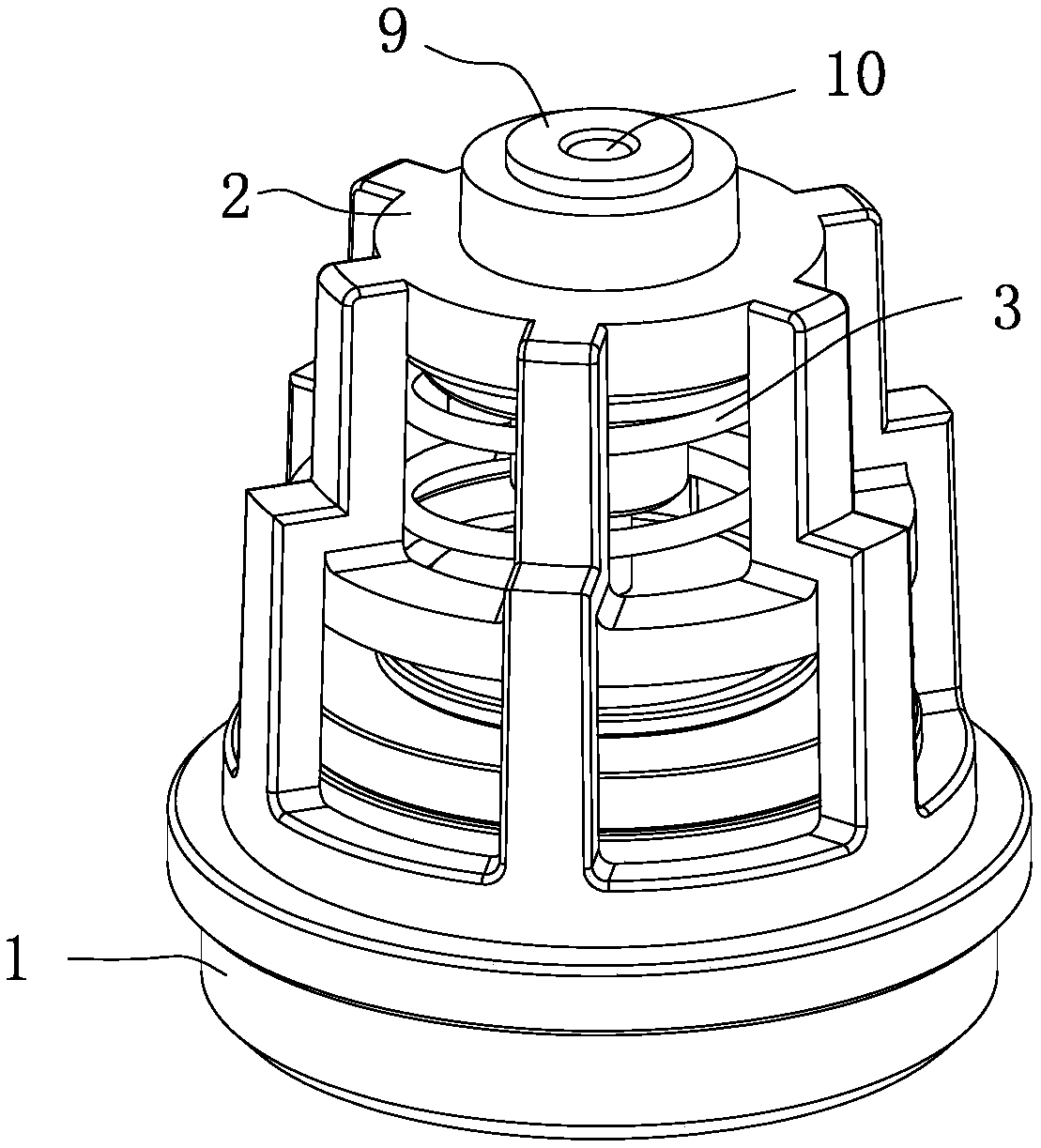

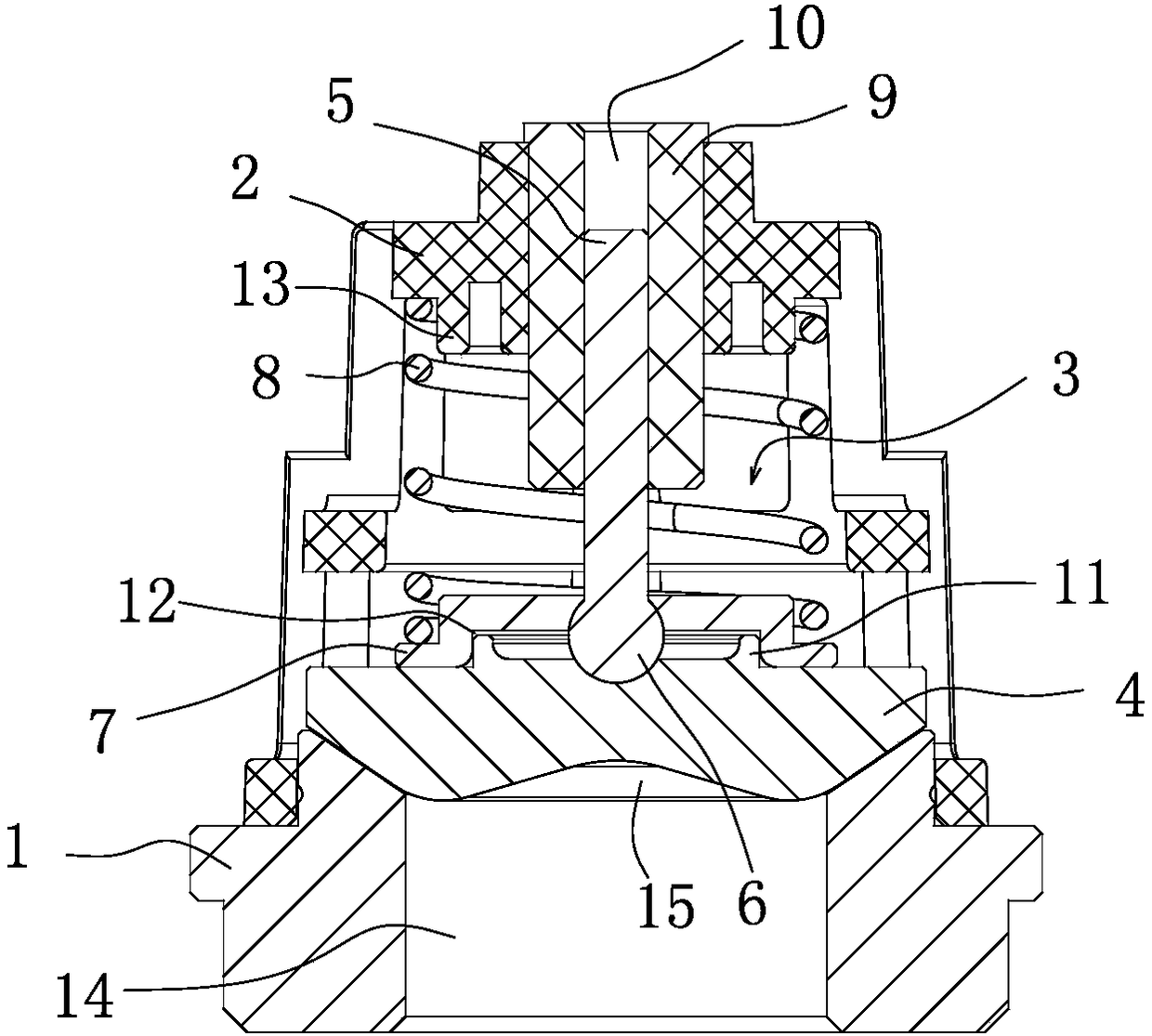

[0021] Such as figure 1 and figure 2 As shown, a high-pressure check valve suitable for a high-pressure plunger pump of a washing machine includes a valve seat 1 and a valve cover 2 fixedly connected to the valve seat 1, and the valve seat and the valve cover are in a sealed connection. The valve cover 2 is provided with an elastic pressing part 3, and a valve plate 4 between the elastic pressing part 3 and the valve seat 1. The valve cover 2 is provided with a valve capable of reciprocating vertically. Core 5, the axis line of the valve core 5 coincides with the axis line of the valve cover 2, and the end of the valve core 5 near the valve plate 4 has a ball head 6, and the valve plate 4 is provided with a ball The contact surface of the head 6 that is matched and recessed toward the inside of the valve plate 4 , the valve core 5 passes through the elastic pressing member 3 and the ball head 6 is located below the elastic pressing member 3 so that the ball head 6 is pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com