Threaded connecting mechanism capable of preventing looseness and transmitting torque

A technology for transmitting torque and threaded connection. It is used in mechanical equipment, rigid shaft couplings, couplings and other directions. It can solve the problems of exposed anti-loosening threaded holes, damage to the aesthetic feeling, and inability to reliably transmit torque to the rotor shaft. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

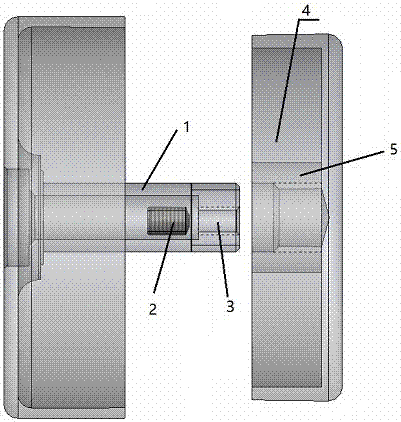

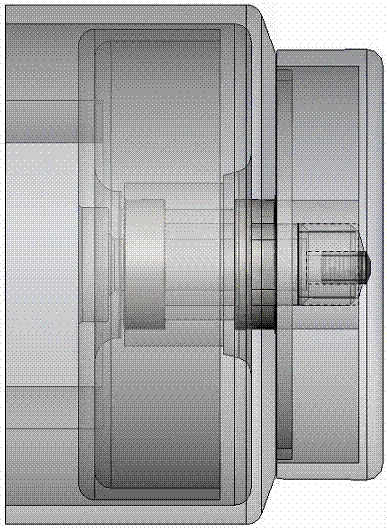

[0020] According to an embodiment of the technical solution proposed by the present application, such as figure 1 , figure 2 As shown, a threaded connection mechanism that prevents loosening and can transmit torque is located at the connection between the rotor shaft 1 and the structural arm 4, and the shaft end of the rotor shaft 1 is connected with the structural arm 4 through a threaded structure, so The shaft end of the rotor shaft 1 is provided with a machine screw 2 arranged parallel to its axis. The front end of the machine screw 2 touches the structural arm 4 to lock the rotor shaft 1 and the structural arm 4. Tighten to prevent mutual rotation at the connecting threads of the two.

[0021] According to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com