Permanent magnet auxiliary synchronous reluctance motor employing asymmetric rotor sheets

A technology of rotor punching and auxiliary synchronization, which is applied to magnetic circuits, magnetic circuits, and electric components characterized by magnetic materials, and can solve problems such as large electromagnetic noise and vibration, no self-starting operation, and large torque ripple. Achieve the effect of improving power factor, improving operating efficiency and reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

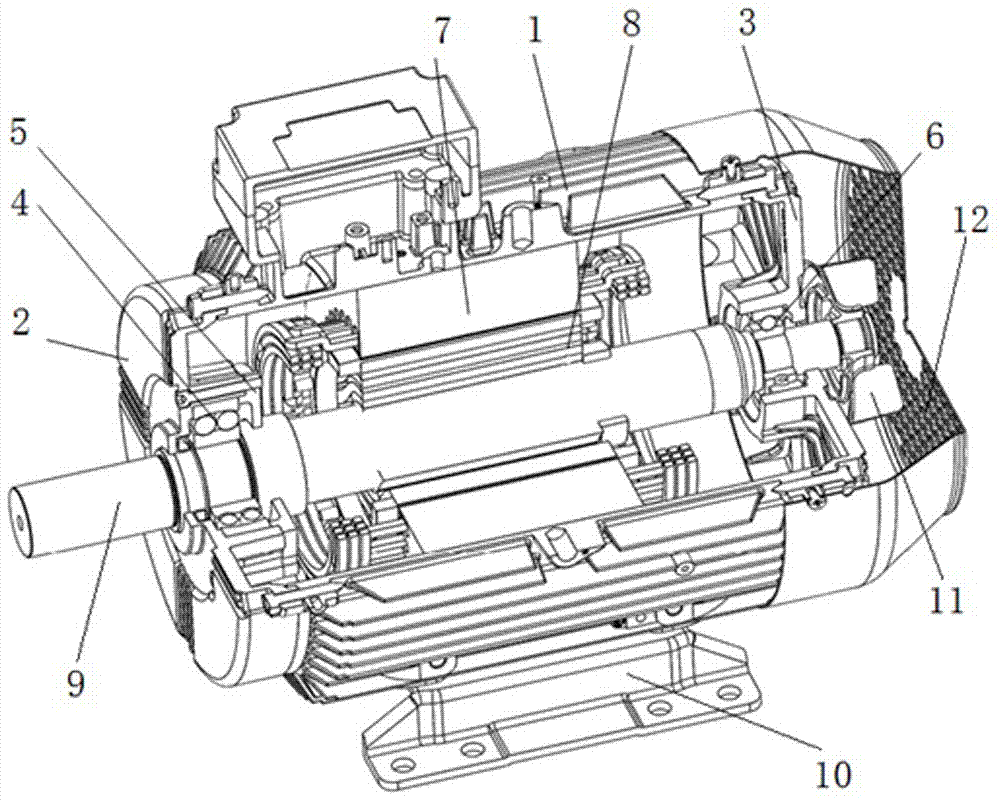

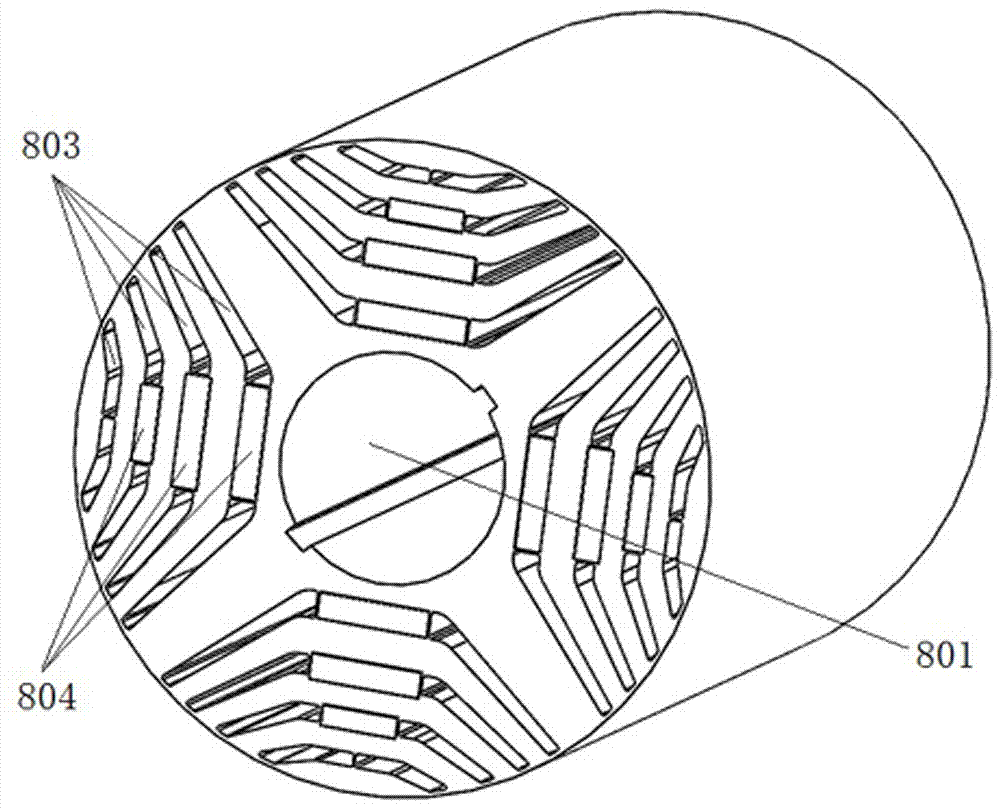

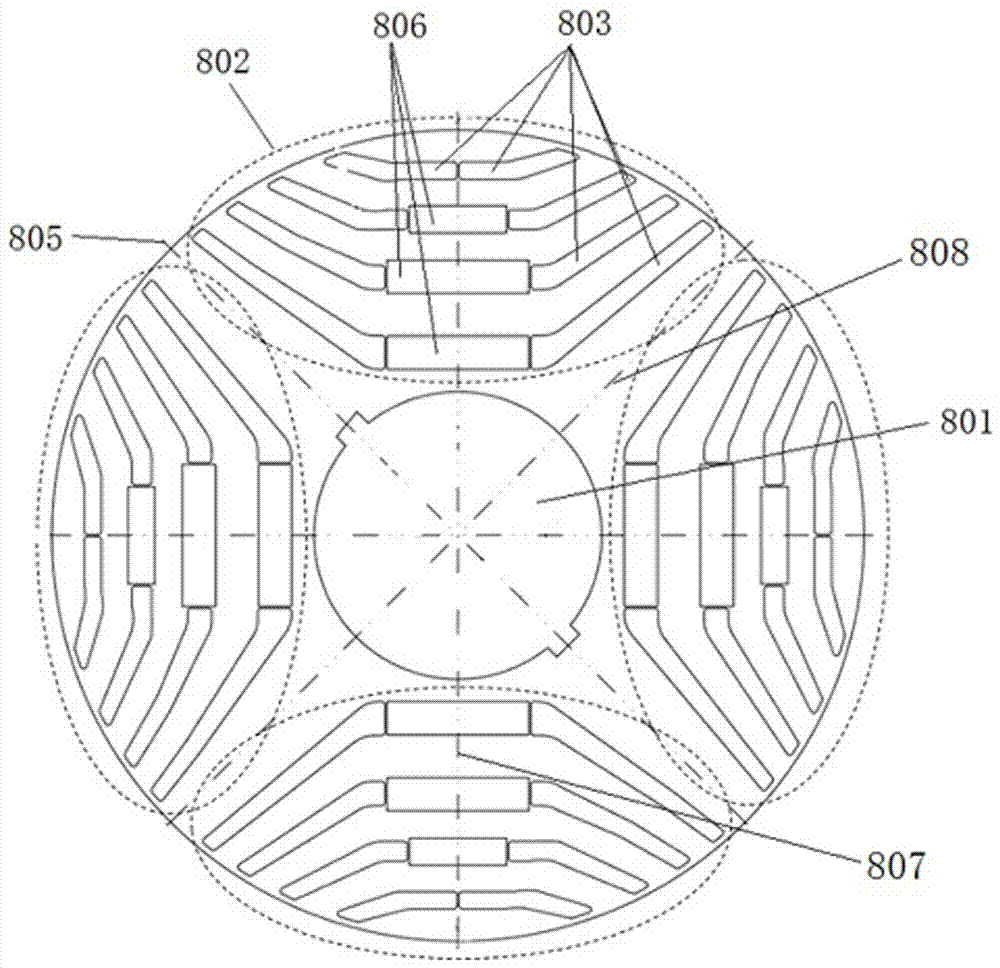

[0025] Such as Figure 1-3 As shown, a permanent magnet assisted synchronous reluctance motor adopts an asymmetric rotor punching plate, including a base 1, a front end cover 2, a rear end cover 3, a front bearing 4, a front bearing inner cover 5, a rear bearing 6, and a rear bearing inner cover Cover, wire stator 7, rotor core 8, rotating shaft 9, feet 10, fan blades 11, wind cover 12, rotor core 8 is formed by stacking iron core punching sheets of 4 magnetic poles 802, each magnetic pole 802 The geometric center line is the magnetic pole axis 807, the center of the iron core punching sheet is provided with a rotating shaft hole 801, and each magnetic pole 802 is provided with a permanent magnet group, and each permanent magnet group includes 3 permanent magnets 804 arranged along the magnetic pole axis 807, Both sides of each perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com