Wire saw

A wire saw and wire cutting technology, applied in the field of wire saw, can solve problems such as low-density frames, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

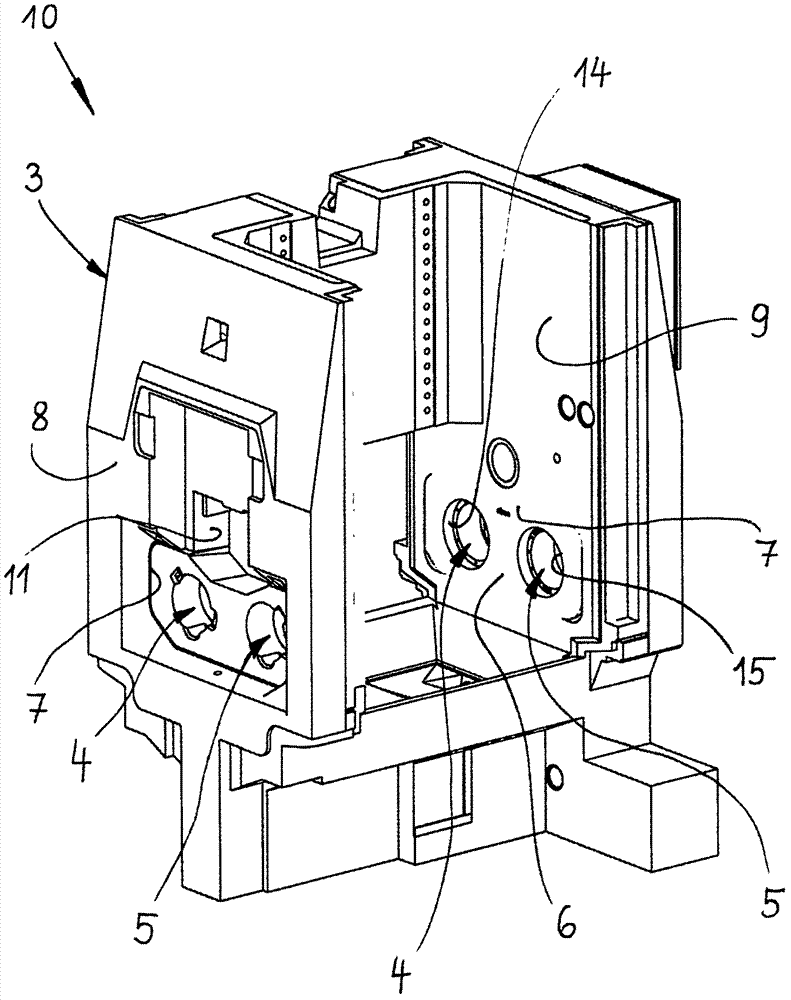

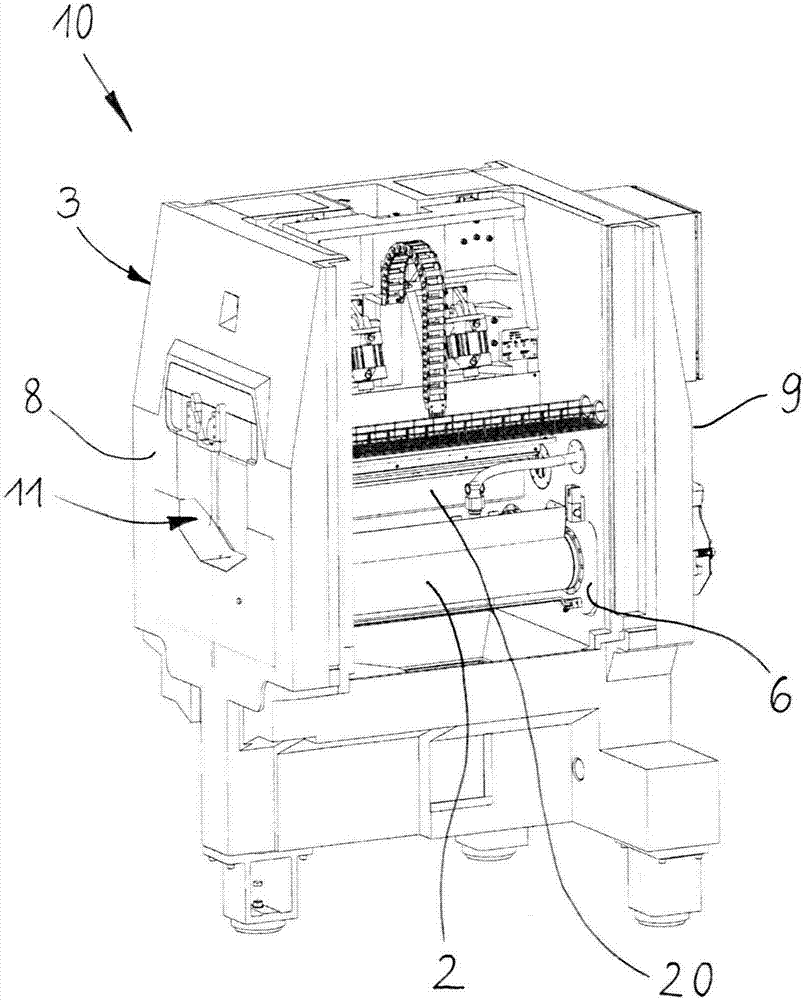

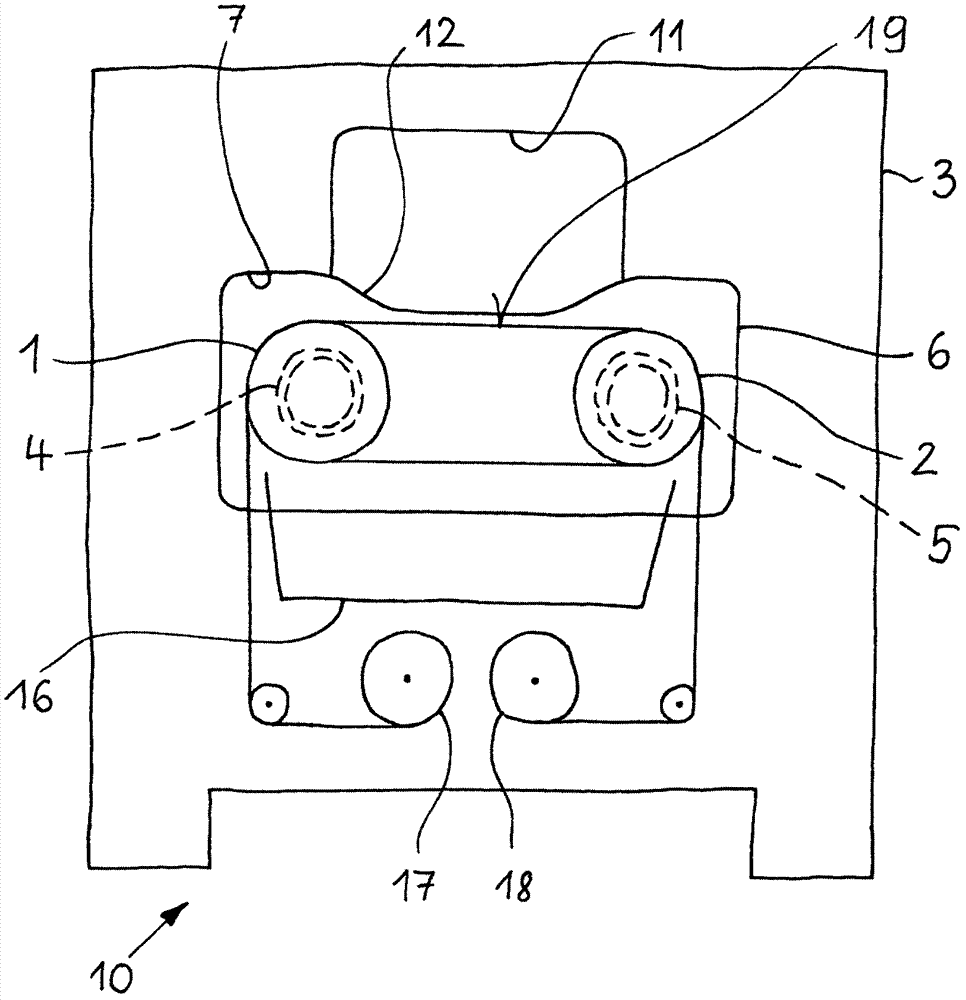

[0055] figure 2 and image 3 A wire saw 10 according to the invention is shown for cutting a block of material 20 , in particular for slicing, squaring and / or squaring a block of material such as hard and brittle material and / or semiconducting material. figure 1 Shows figure 2 Frame 3 of the jigsaw 10 shown in .

[0056] The wire saw 10 comprises a first wire guide roller 1 and a second wire guide roller 2 for supporting a cutting area 19 formed by the cutting wire. The frame 3 supports the wire guide rollers 1 and 2, and is made of a first material. Wire guide rollers 1 and 2 are rotatably mounted to frame 3 through bearings 4 and 5 .

[0057] The wire saw 10 comprises at least one common bearing housing 6 in which a first bearing 4 for supporting the first wire guiding roller 1 and a second bearing 5 for supporting the second wire guiding roller 2 are housed. exist figure 1 and figure 2 In the preferred embodiment of the present invention, the wire saw 10 comprises...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com