A kind of inner hole support device for thin-walled rotating body parts

A technology of supporting devices and rotating bodies, which is applied in positioning devices, metal processing machinery parts, supports, etc., can solve the problems of tooling shape limitation and poor versatility, and achieve the effect of improving versatility and expanding the processable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

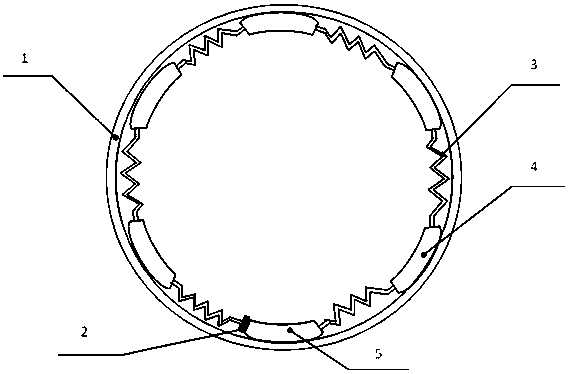

[0012] A support device for the inner hole of a thin-walled revolving body part, comprising: an adjusting nut 2, a spring screw rod 3, a connecting block 4 and an adjusting block 5.

[0013] There are six spring screws 3, the middle of each spring screw 3 is a spring, and the two ends are screw rods; the connecting block 4 is arc-shaped, and the two ends have threaded holes that match the spring screw 3. The adjustment block 5 is arc-shaped, with a threaded hole matching the spring screw rod 3 at one end, and a light hole with a diameter 0.3mm larger than the thread diameter of the spring screw rod 3 at the other end.

[0014] The six spring screws 3 are connected alternately and sequentially with the five connecting blocks 4, and the adjacent spring screws 3 and the connecting blocks 4 are screwed and fixed, and the head end and the end are both spring screws 3; The threaded holes are fixedly connected, and the end of the end spring screw rod 3 is installed in the light hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com