Rubber mixing chamber facilitating burdening

A technology of rubber banburying and banburying, which is applied in the field of rubber banburying room for convenient batching, which can solve the problems of prolonging banburying time, increasing production cost, and difficult dispersion of ingredients, so as to shorten banburying time and precise banburying operation the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

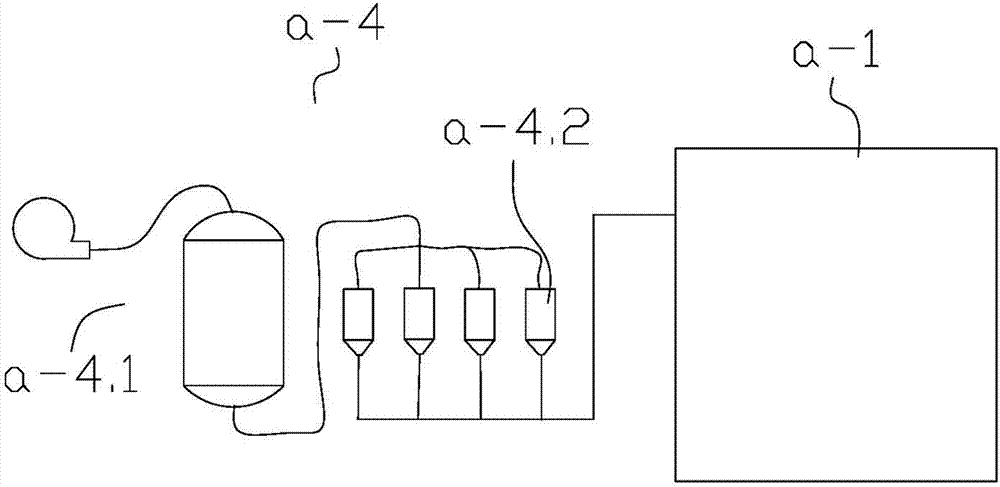

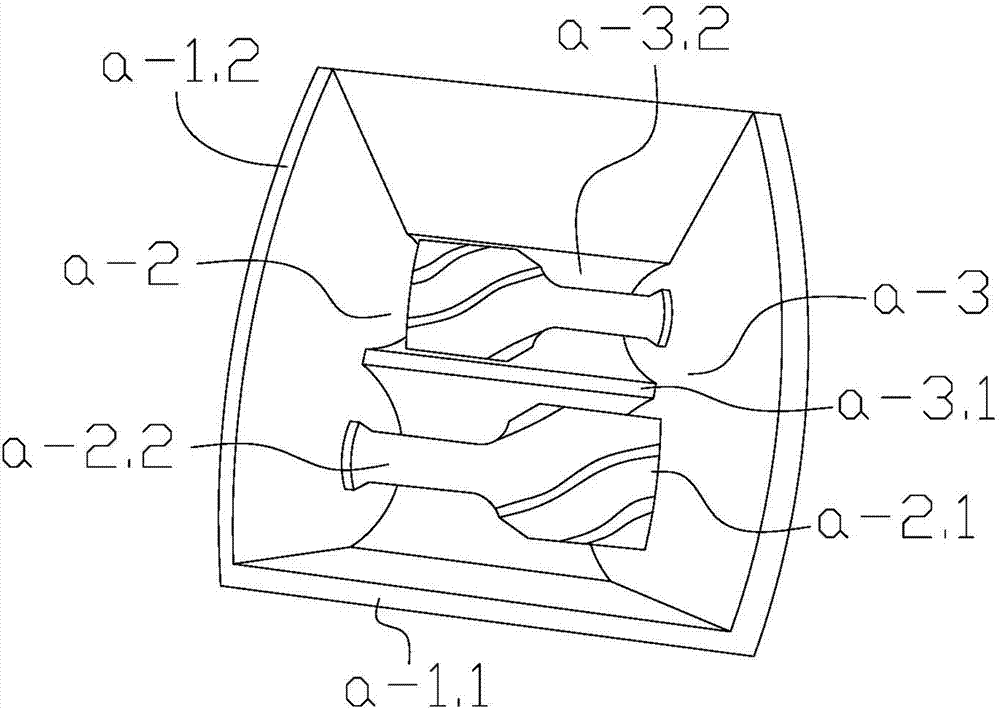

[0027] Example 1: Reference figure 1 and figure 2 , a rubber mixing chamber for convenient batching, including:

[0028] A banburying shell a-1 with an upper opening, the surrounding of the banburying shell a-1 is composed of four side plates, and the side plates include two opposite planar side plates a with a flat upper surface -1.1, and an arc side plate a-1.2 connecting the two ends of the two planar side plates a-1.1 and having an arc surface on the upper surface;

[0029] Two parallel banburying rolls a-2 arranged side by side in the banburying shell a-1, the two ends of the banburying roll a-2 are hinged in the banburying shell a-1 through the rotating shaft , one end of which is a spiral stirring part a-2.1, which is provided with a spiral-shaped stirring protrusion, and the other end is a rotating shaft part a-2.2, and the position of the spiral stirring part a-2.1 on the banburying roller a-2 is the same as The position of the rotating shaft part a-2.2 on the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com