Automation environment-friendly carriage

A carriage, environmental protection technology, applied in the direction of motor vehicles, vehicles used for freight, load coverage, etc., can solve the problems of reduced service life, difficult overall installation, environmental pollution, etc., to reduce damage, reduce economic costs, and avoid direct effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

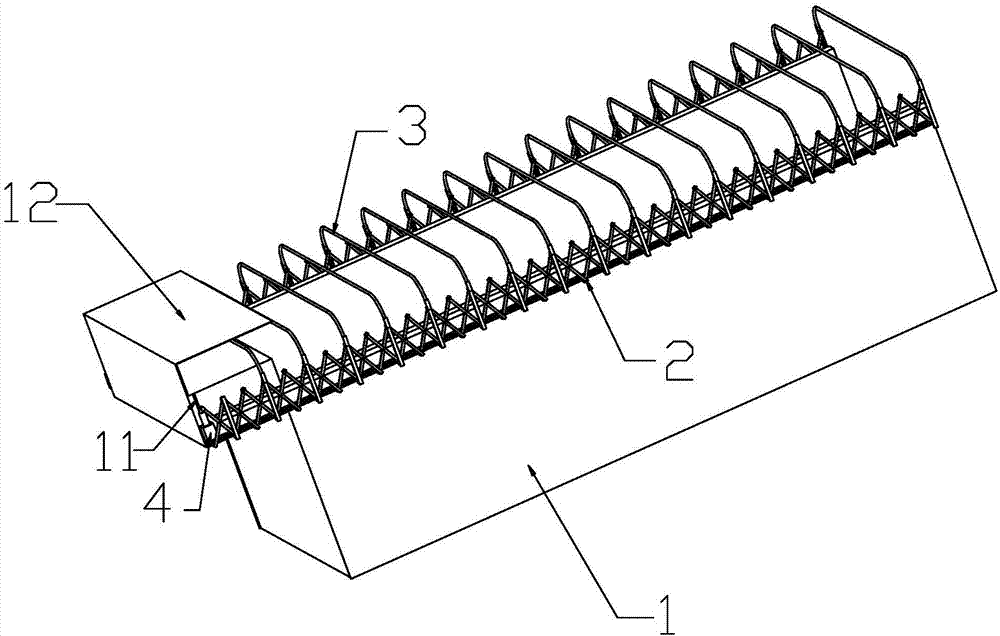

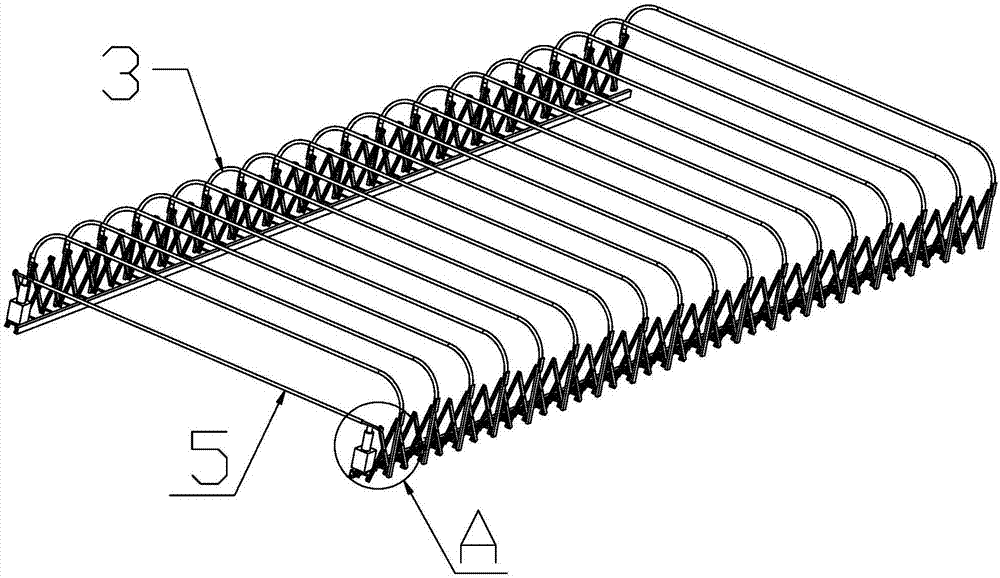

Embodiment 1

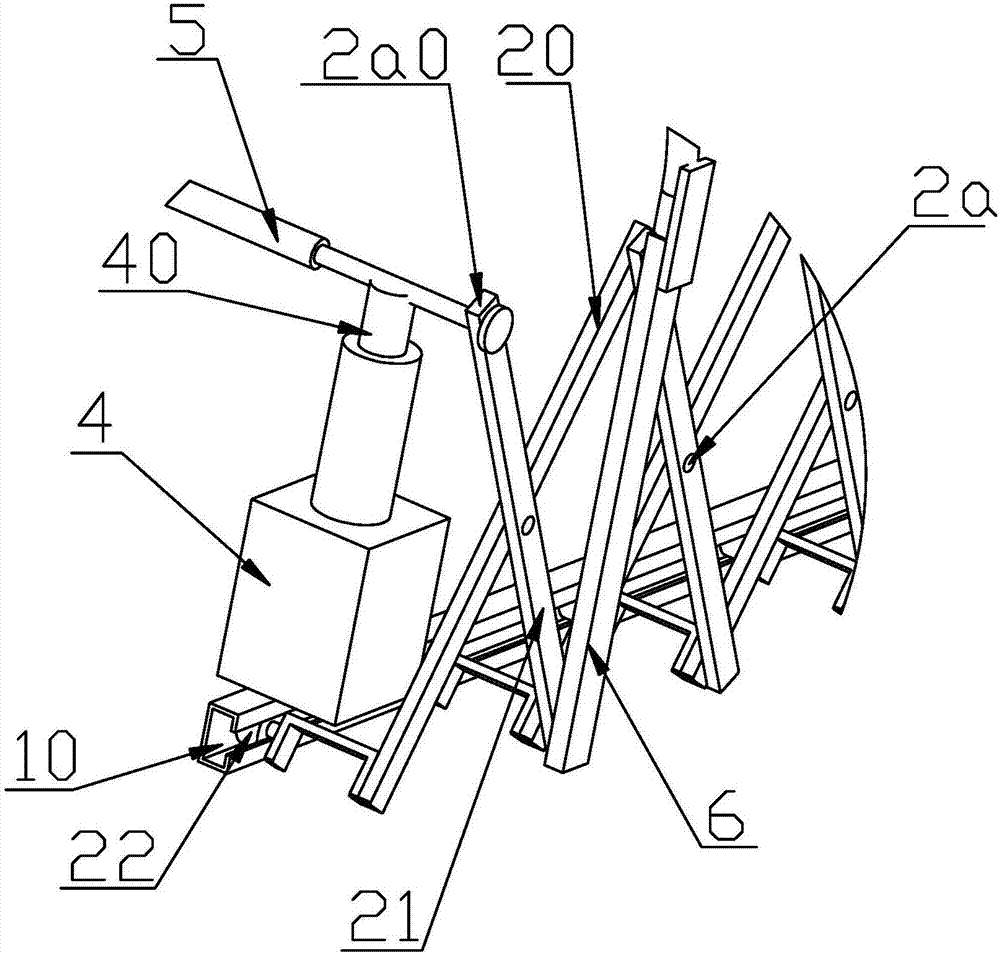

[0038] In the first embodiment, the driving mechanism is the main hydraulic cylinder 4, and the main hydraulic cylinder is a 4-position bidirectional two-stage hydraulic cylinder, which can realize independent expansion and contraction. The main hydraulic cylinder 4 is set vertically upward, and its piston rod A40 faces upward. It is supported on the corresponding piston rod A40, so that the telescopic fork 2 can be stretched quickly by pushing and pulling the connecting rod 5 through the main hydraulic cylinder 4.

[0039]Car body 1 both sides is provided with slideway 10 directly to the position of telescopic fork frame 2 bottoms, and slideway 10 is arranged along the length direction of car body 1, and its length is similar to the length of car body 1, and the lower end of each inner fork bar 20 can Mounting seat 23 is detachably connected, the mounting seat 23 is perpendicular to the axis of the inner fork rod 20, and extends directly to the slideway 10, and the mounting se...

Embodiment 2

[0044] In the second embodiment, the oil return circuit of the main hydraulic cylinder 4 is connected in parallel with the oil inlet circuit of the auxiliary hydraulic cylinder 7, and the oil inlet circuit of the main hydraulic cylinder 4 and the oil inlet circuit of the auxiliary hydraulic cylinder 7 are respectively equipped with electromagnetic On-off valve A4a and electromagnetic on-off valve B4b, when the electromagnetic on-off valve A4a is opened and the electromagnetic on-off valve B4b is closed, the hydraulic station 8 supplies oil to the main hydraulic cylinder 4 to make the piston rod A40 stretch out, so that the retraction of the telescopic fork 2 can be realized and when both the electromagnetic switch valve A4a and the electromagnetic switch valve B4b are opened, the hydraulic station 8 reversely supplies oil to the main hydraulic cylinder 4, and the piston rod A40 shrinks, and while supplying oil to the main hydraulic cylinder 4, it can The auxiliary hydraulic cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com