Steel sleeve pressing device for hubs

A steel sleeve and wheel hub technology, applied in transportation and packaging, metal processing, metal processing equipment, etc., can solve the problems of insufficient pressing of the steel sleeve and leakage of the steel sleeve, and achieve the effect of avoiding human influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

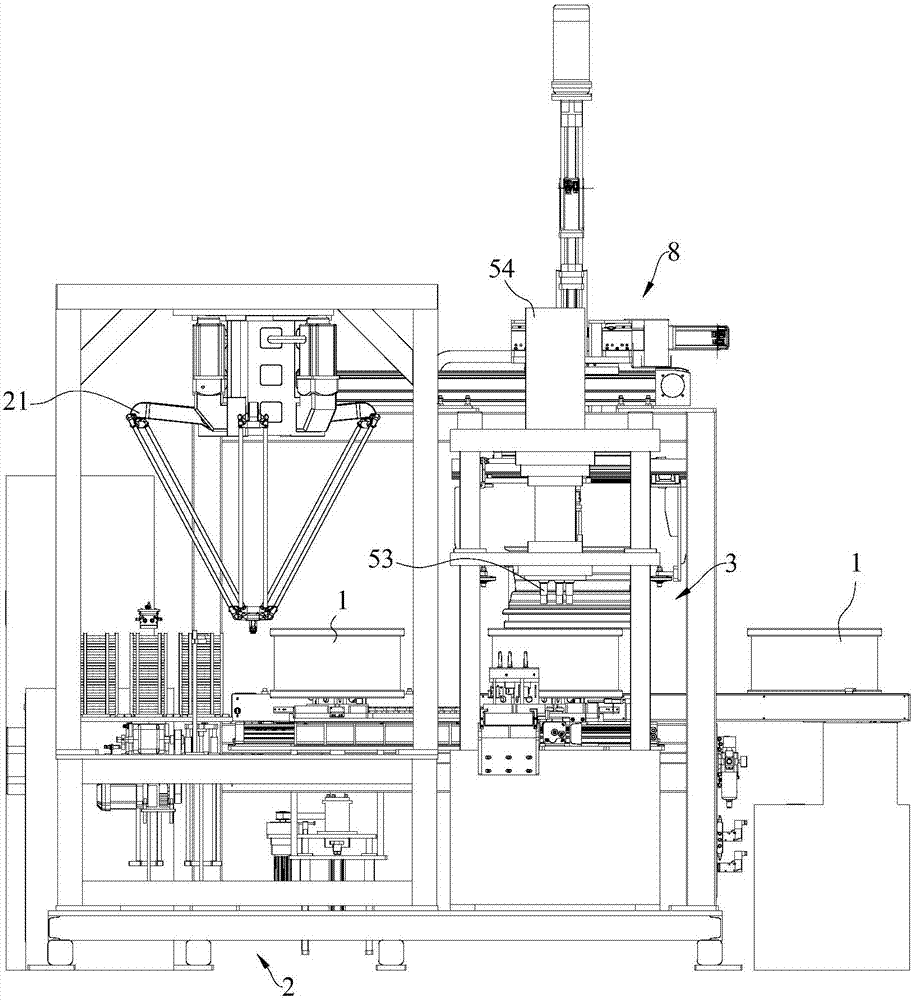

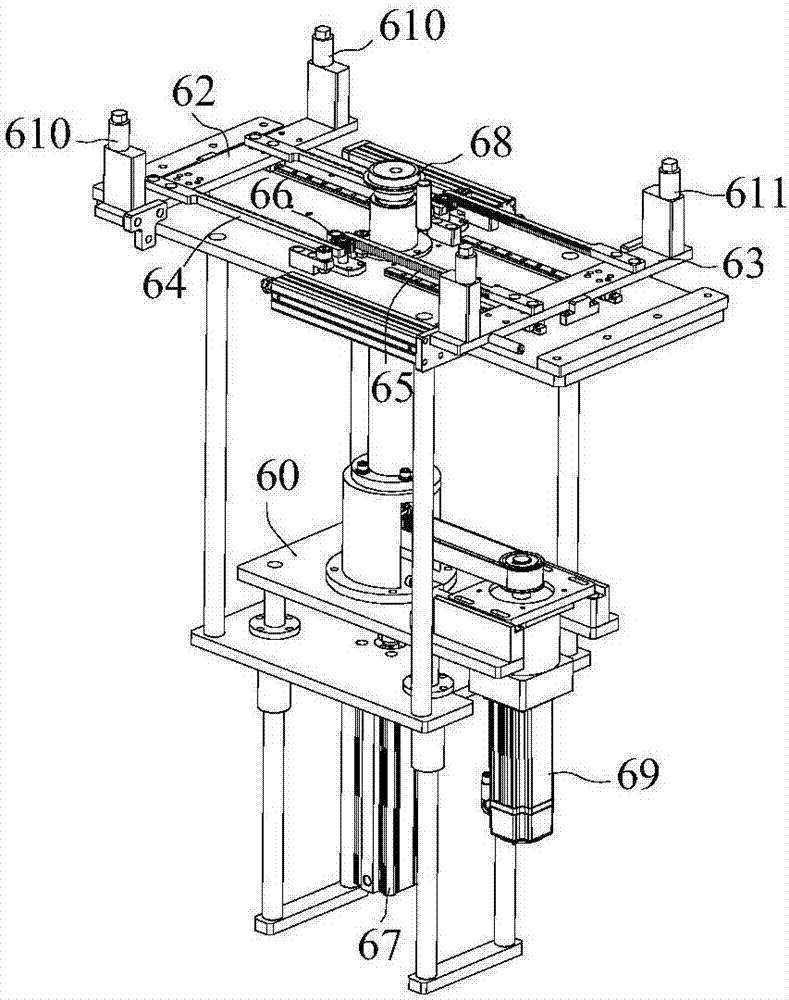

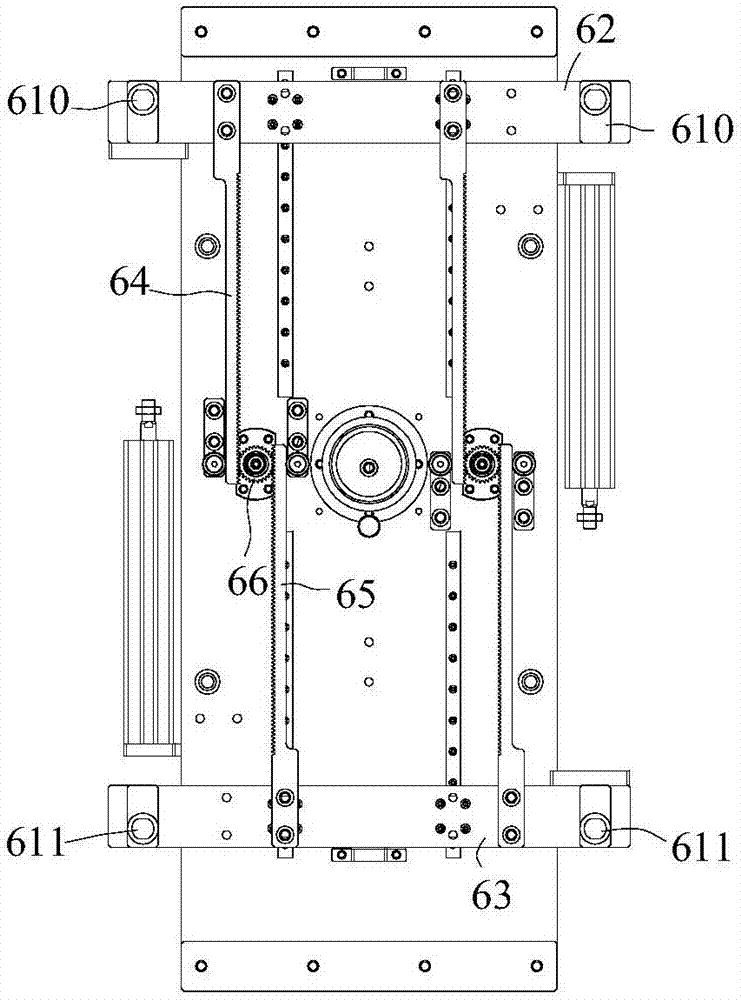

[0026] refer to Figure 1 to Figure 7 , which shows the specific structure of a preferred embodiment of the present invention, and the structural characteristics of each component of the present invention will be described in detail below.

[0027] The invention provides a wheel hub pressure steel sleeve device, comprising

[0028] Hub conveying system, the hub conveying system can drive the hub 1 through the steel sleeve pre-installation station 2 and the steel sleeve press-fitting station 3;

[0029] The steel sleeve pre-installation station 2 has a steel sleeve pre-installation manipulator 21 that can pre-install the steel sleeve located in the steel sleeve storage area to the bolt hole of the hub 1;

[0030] The steel sleeve pressing station 3 has a steel sleeve pressing mechanism that can press the steel sleeve pre-installed on the bolt hole to the wheel hub 1 .

[0031] During work, the wheel hub 1 passes through the steel sleeve pre-installation station 2 and the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com