Automatic screw tightening device

A screw and automatic technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the fuse cover screws cannot be tightened at the same time, the quality of the cover is greatly affected, and the labor intensity of workers is high, so as to reduce the labor force. Effect of labor intensity, quality improvement, reduction of production process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

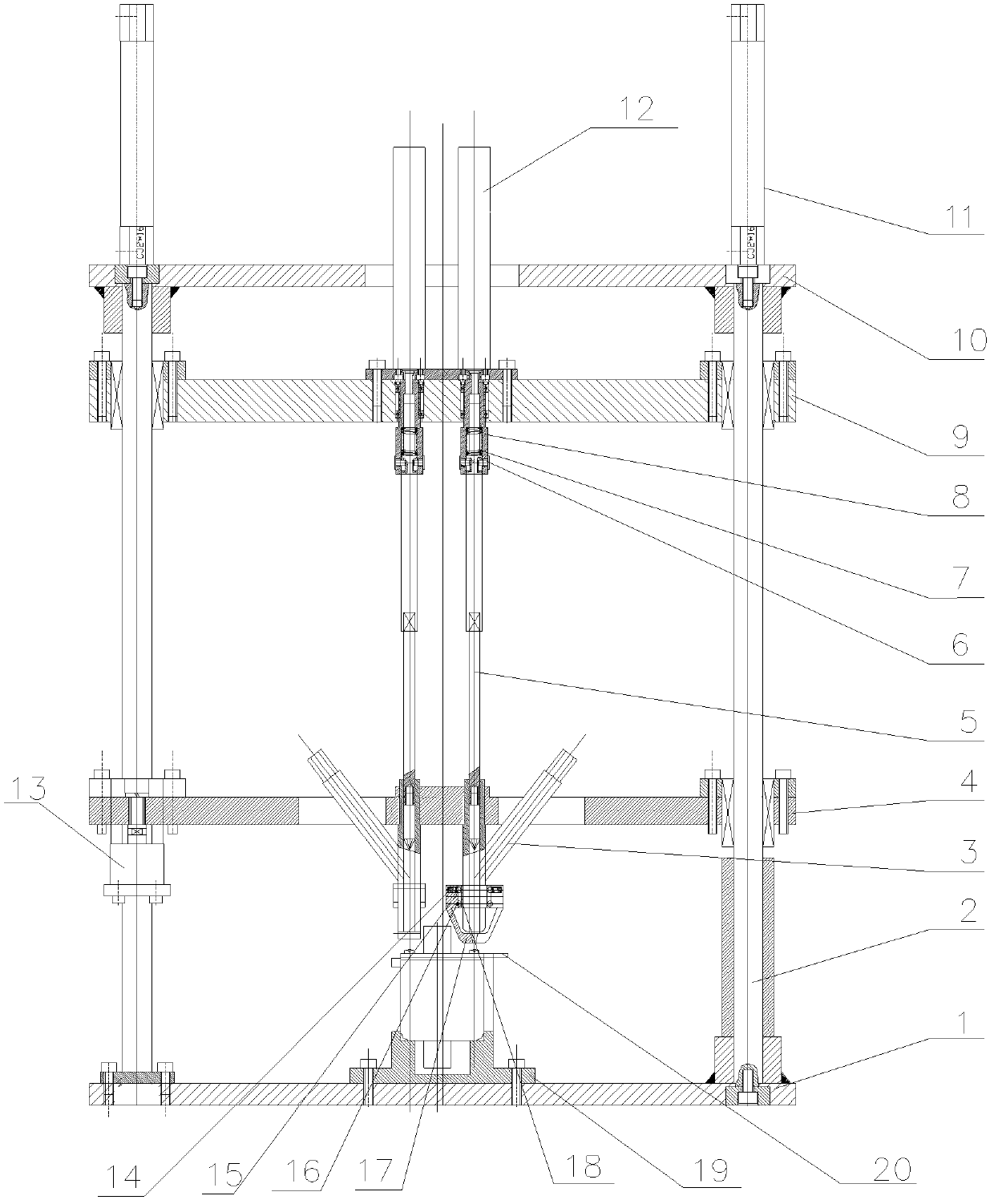

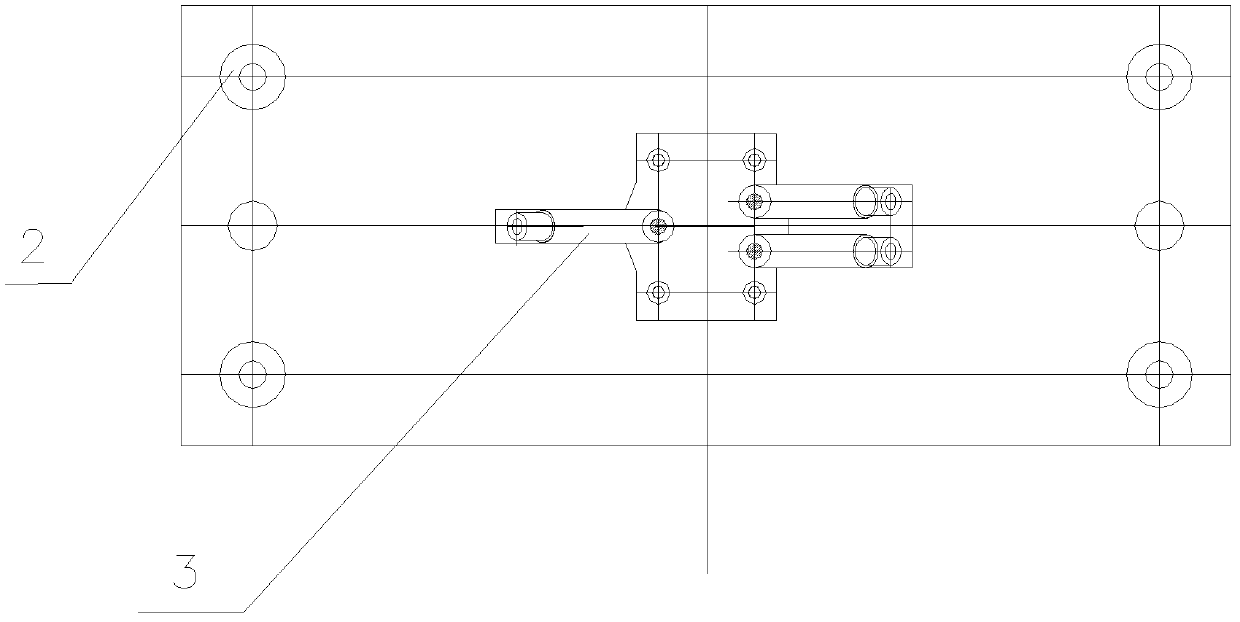

[0027] Such as figure 1 , 2 As shown, an automatic screw tightening device includes frame parts, guide parts, moving tightening parts, screw guide parts and auxiliary parts.

[0028] The frame part includes a base plate 1, an upper cover plate 10 and four circular guide rails 2 connecting the base plate 1 and the upper cover plate 10, and the four circular guide rails 2 parallel to each other provide moving guides for the guide parts and the moving tightening parts.

[0029] Guide parts comprise screw guide bucket 3, moving guide plate 4 and guide cylinder 13, described moving guide plate 4 and guide cylinder all 13 are arranged on the circular guide rail 2, and the piston rod of guide cylinder 13 is arranged on the move guide plate 4, and cylinder body is provided with On the bottom plate 1, the moving guide plate 4 is connected to the guide cylinder 13, and is driven to move up and down along the circular guide rail 2 by the guide cylinder 13. The screw guide barrel 3 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com