Reciprocating type sampling method and device for gas content fixed-point sampling

A technology of fixed-point sampling and gas content, which is applied in sampling devices, measuring devices, and undisturbed core extraction devices, etc., can solve problems such as poor drilling stability, accelerated gas desorption of coal samples, and failure to consider gas loss, etc., and achieves improved sampling. Speed, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A reciprocating sampling method for fixed-point sampling of gas content, specifically comprising the following steps:

[0021] 1) The hollow drill pipe with the coal core pipe fixed at the front end is drilled in sections according to the predetermined drilling path. Take out together along the inner hole of the hollow drill pipe, and take out the rock formation from the coal core pipe, then push the coal core pipe along the inner hole of the hollow drill pipe to the front end of the hollow drill pipe and fix it, and then drill the hole as planned path for the next section of drilling;

[0022] 2) When the hollow drill pipe is drilled to the predetermined sampling depth, a sealing air bag connected with an inflatable pipeline is installed at the front opening of the coal core pipe, and then the coal core pipe is pushed into the hollow drill pipe along the inner hole of the hollow drill pipe The front end of the coal core tube is fixed, the hollow drill pipe is drilled ...

Embodiment 2

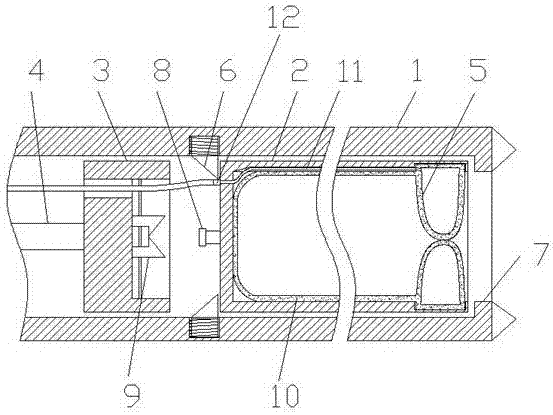

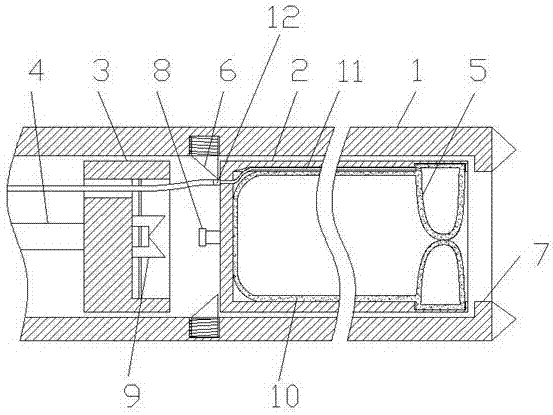

[0025] Such as figure 1 As shown, a reciprocating sampling device for fixed-point sampling of gas content includes a hollow drill pipe 1, a coal core pipe 2 and a coring rod 4; the coal core pipe 2 is a cylinder with one end open, and the outer diameter of the cylinder is the same as The inner diameter of the hollow drill pipe 1 matches; the front end of the inner wall of the hollow drill pipe 1 is provided with a coal core pipe front limit 7 and a coal core pipe rear limit 6 for fixing the coal core pipe 2, and the coal core pipe front limit 7 is a fixed limit, and the rear limit of the coal core pipe 6 is a one-way limit set along the rear; the core rod 4 is a hard drill rod, and the front end of the core rod 4 is provided with a detachable connector 3 , the connector 3 is used to drive the rear limit 6 of the coal core pipe and connect with the coal core pipe 2.

[0026] The inner side wall of the opening of the coal core pipe 2 is provided with an annular groove, and an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com