A Method for Predicting the Complexity of Hydraulic Fractures Based on Core Residual Stress Level

A technology of residual stress and hydraulic cracks, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, strength characteristics, etc., can solve problems such as inability to carry out engineering design guidance, and achieve low cost and simple modeling operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1. A method for predicting the complexity of hydraulic fractures based on the core residual stress level, characterized in that the method comprises:

[0034] Step 1: test the static rock mechanics parameters of the sampled core in the implementation well;

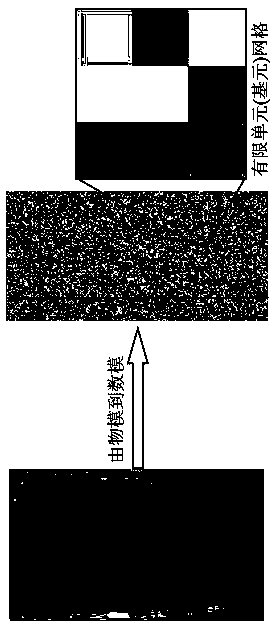

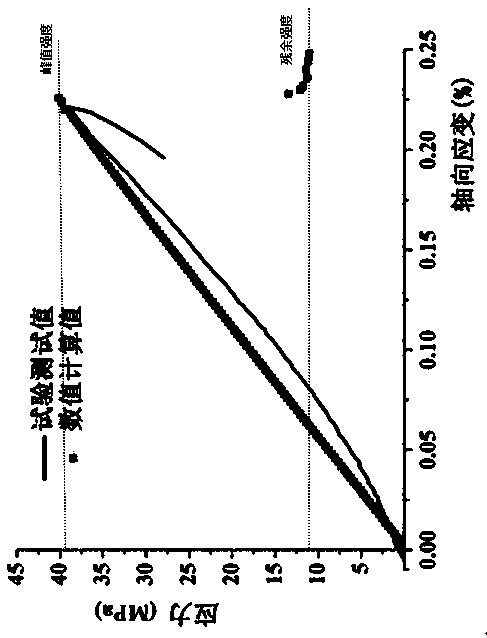

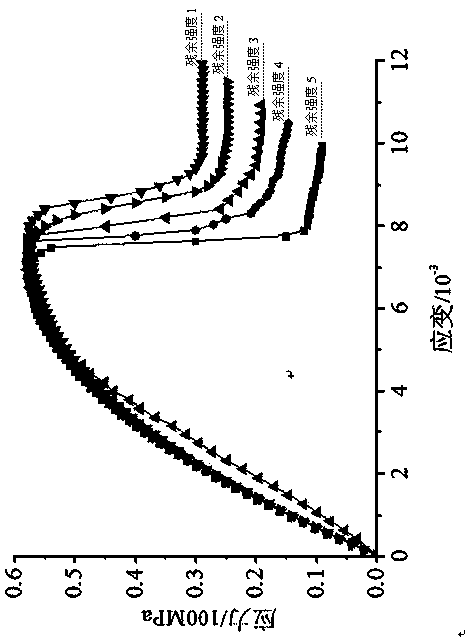

[0035] Step 2: Carry out digital simulation tests of rock mechanics parameters based on numerical cores to obtain fine residual strength characteristics of reservoir rock mass;

[0036] Step 3: Establish different finite element analysis models for reservoirs with different layers and residual stresses in the implemented wells, and calculate the hydraulic fracture complexity index for predicting the hydraulic fracture complexity.

[0037] In step 1, the static rock mechanics parameters are static elastic modulus, uniaxial compressive strength, uniaxial tensile strength, residual strength, and static Poisson's ratio.

[0038] In step 2, the digital-analog test of rock mechanics parameters based on numerical...

Embodiment 2

[0047] Example 2. A method for predicting the complexity of hydraulic fractures based on the residual stress level of the core includes the following steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com