2-magnetic-pole controller-free self-starting permanent magnet auxiliary synchronous reluctance motor

An auxiliary synchronous, reluctance motor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits characterized by magnetic materials, magnetic circuits, etc., can solve the problems of high cost, no self-starting operation function, etc., and achieve less usage , The effect of preventing the risk of high temperature demagnetization and reducing the cost of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

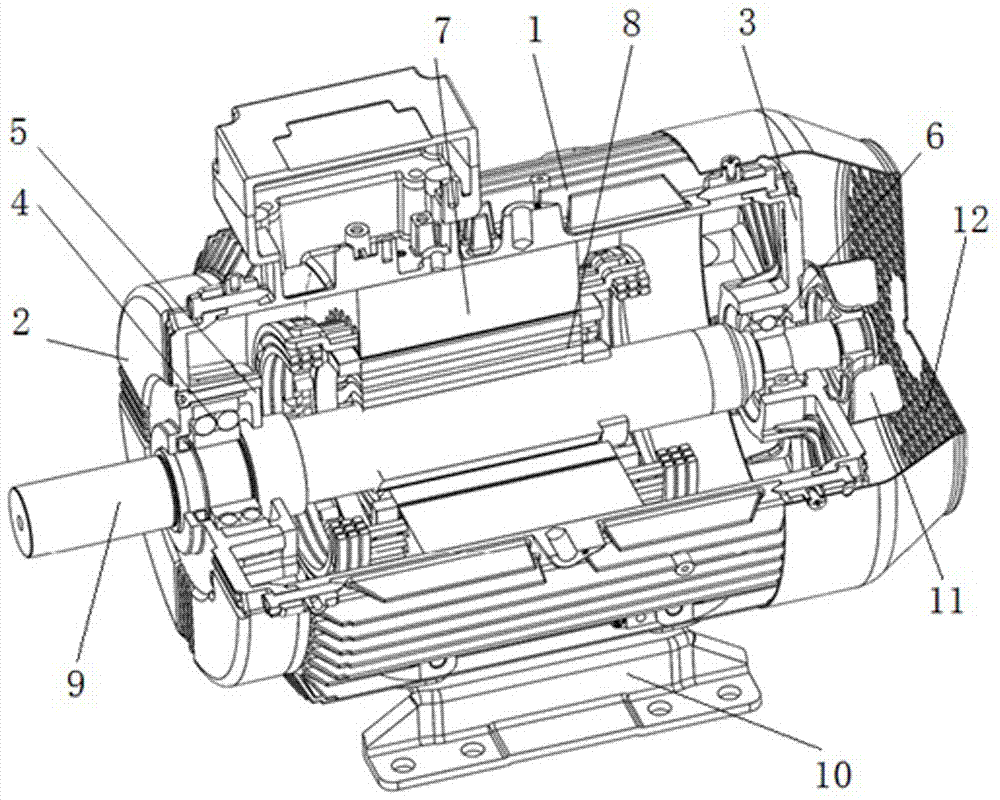

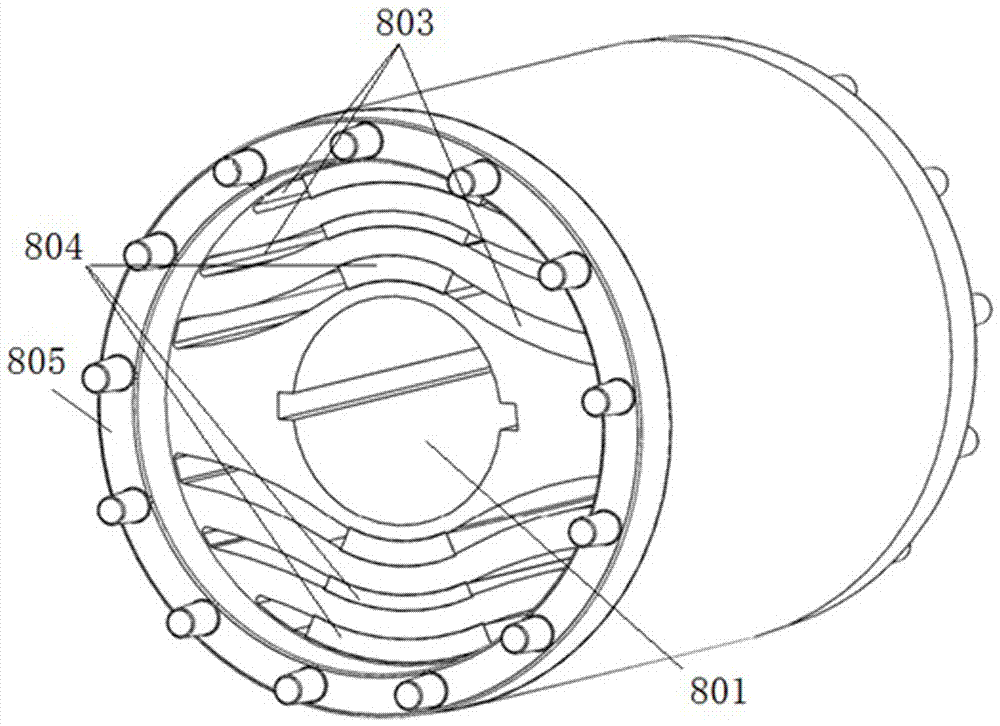

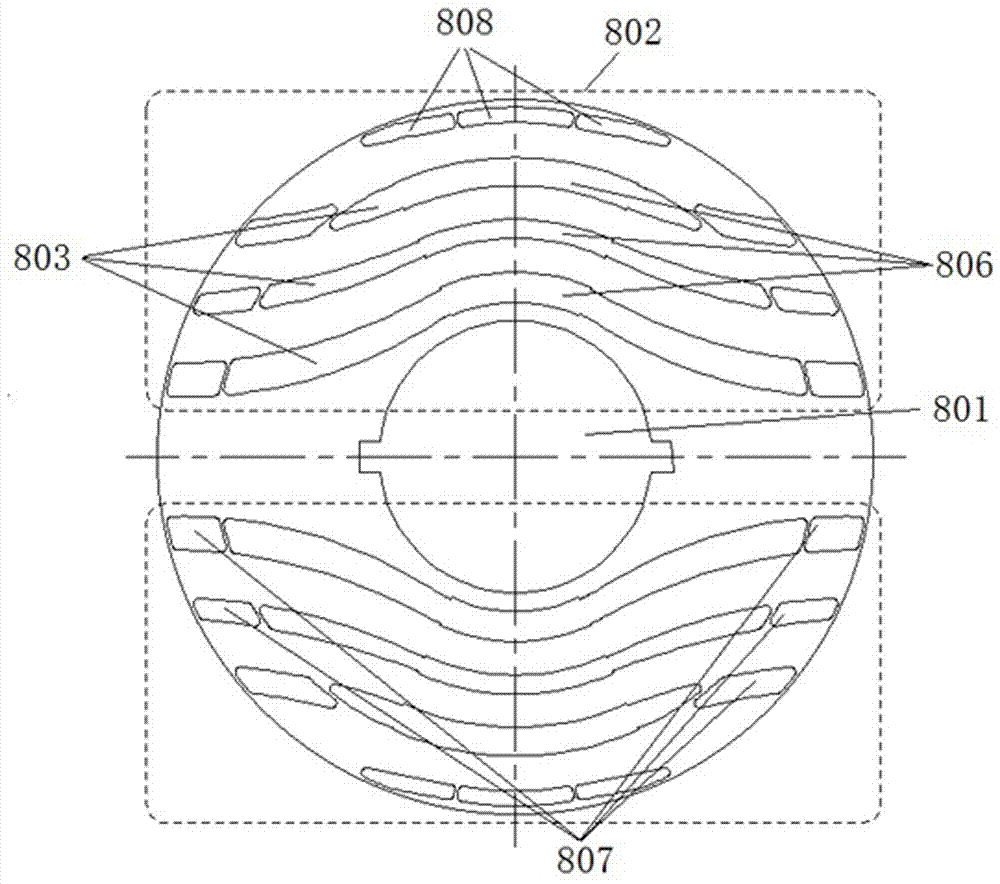

[0024] like Figure 1-3 As shown, a 2-pole non-controller self-starting permanent magnet assisted synchronous reluctance motor, including machine base 1, front end cover 2, rear end cover 3, front bearing 4, front bearing inner cover 5, rear bearing 6, rear bearing Inner cover, wire stator 7, rotor core 8, rotating shaft 9, feet 10, fan blades 11, wind cover 12, rotor core 8 is formed by stacking iron core punches with 2 magnetic poles 802, and iron core punches A rotating shaft hole 801 is provided in the center of the pole, and the two magnetic poles 802 include the same number of radially arranged reluctance slots 803, and a fan-shaped permanent magnet 804 is arranged in the middle of each reluctance slot 803; the rotor core 8 is located in the core punch A cast aluminum squirrel cage 805 is provided on the outer circumference of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com