Rotor structure for improving irreversible demagnetization resisting capability of permanent magnets of permanent magnet motor

A technology of demagnetization ability and rotor structure, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit and other directions, can solve the problem of unstable motor performance, motor performance changes, unable to restore to the initial state, etc. problem, to achieve the effect of improving the resistance to irreversible demagnetization and ensuring the output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further introduced below in combination with specific implementation methods and accompanying drawings.

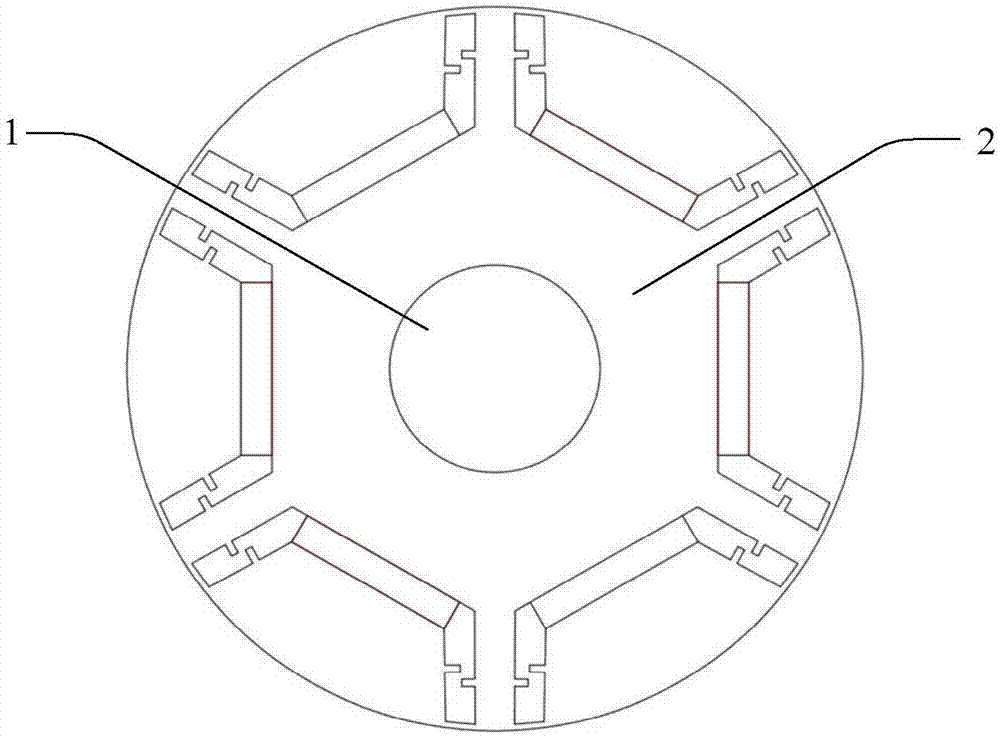

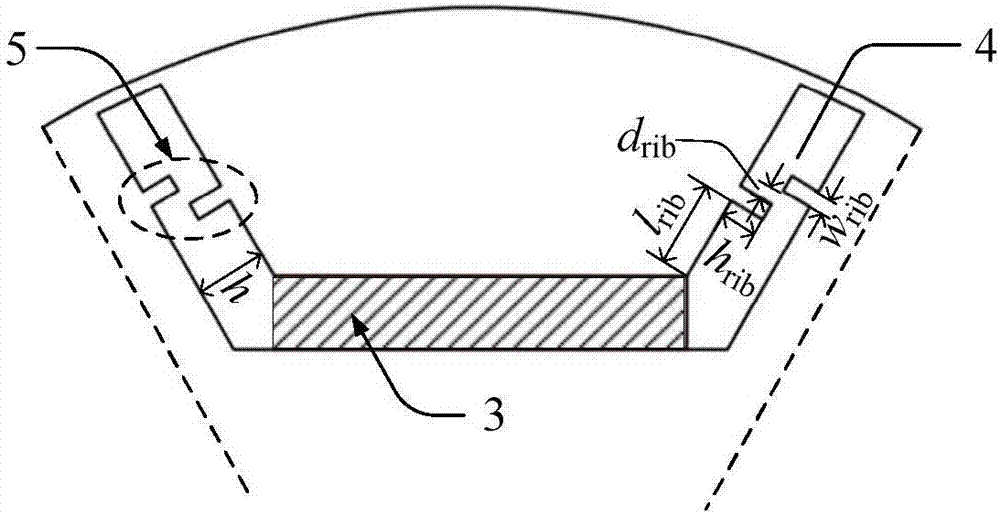

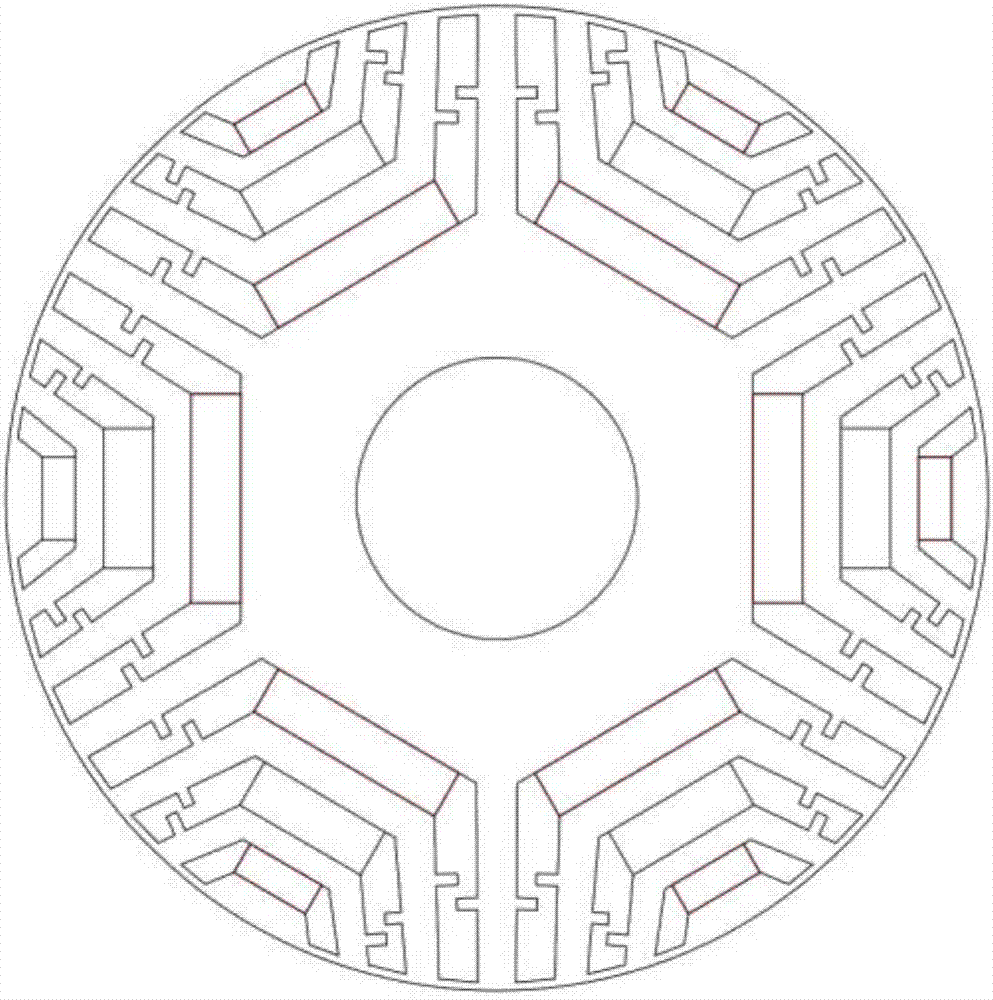

[0018] This specific embodiment discloses a rotor structure that improves the irreversible demagnetization resistance of permanent magnet motors, such as figure 1 As shown, it includes a central rotating shaft 1 and a rotor core 2, and the central rotating shaft 1 and the rotor core 2 are installed on the same central axis. Such as figure 2 As shown, around the central axis, a plurality of U-shaped through-slots 4 of the same shape and size are uniformly arranged on the rotor core 2, and the bottom of the U-shaped through-slot 4 is provided with a permanent magnet 3, and the U-shaped through-slot 4 There are several magnetic bridges 5 that are not connected to each other on the two sides of the tank. Because the magnetic bridges 5 are not connected, the magnetic bridges 5 are also called bypass magnetic brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com