Clamping force-adjustable tangential driving type rotary inertial piezoelectric actuator and method

A piezoelectric actuator and driving technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Inability to act, etc., to achieve the effect of infinite stroke, stable performance, and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

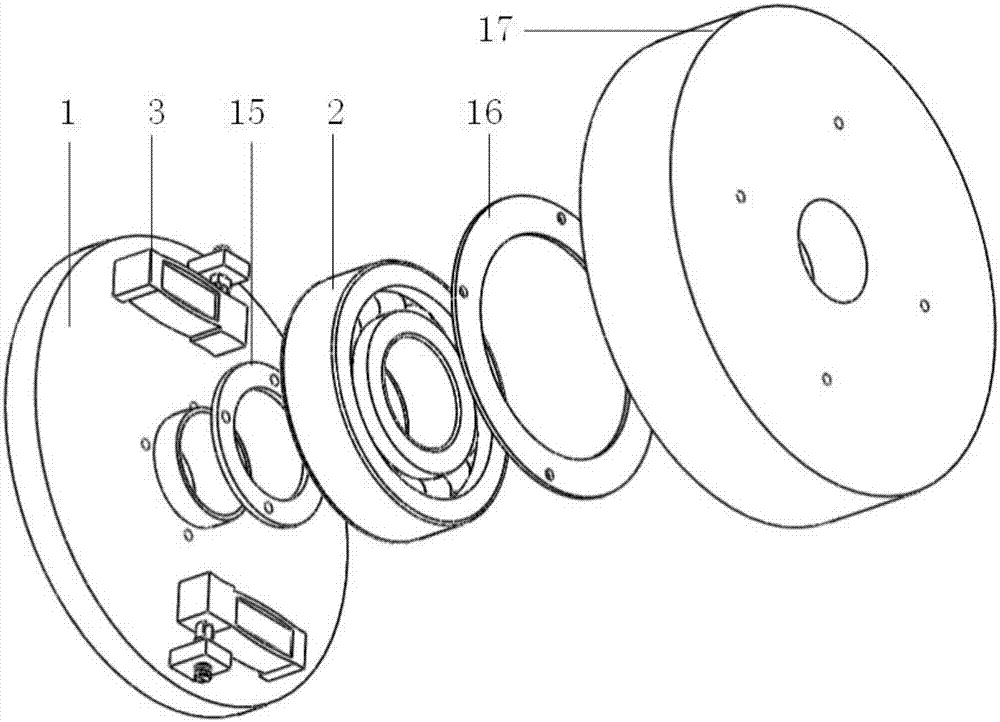

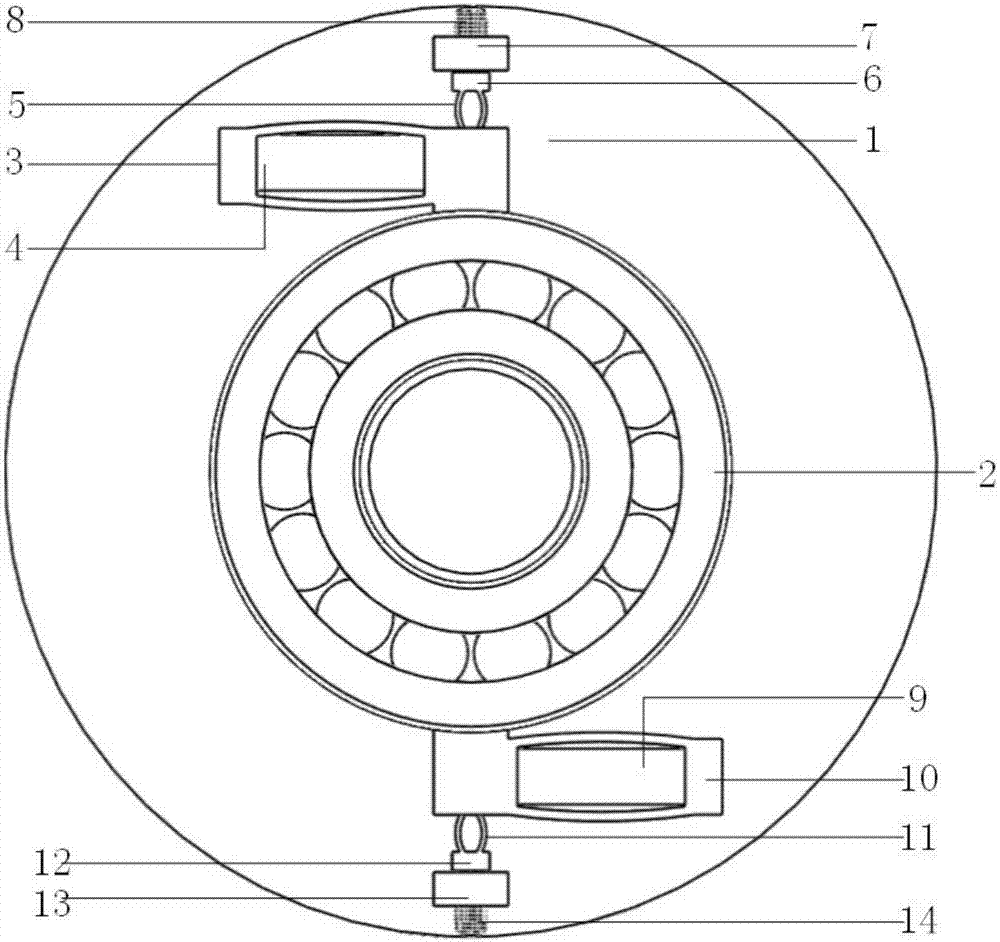

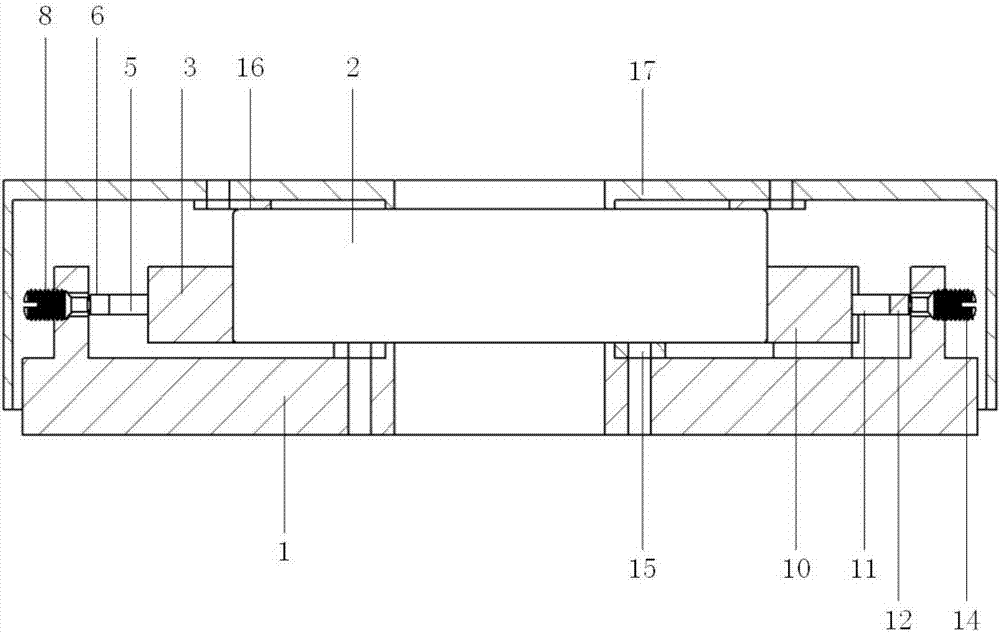

[0022] Such as figure 1 , figure 2 and image 3 As shown, the clamping force adjustable tangentially driven rotary inertial piezoelectric actuator of the present invention, the main parts include base 1, bearing 2, housing 17 and two anti-symmetrically arranged driving mechanisms, the whole structure has rotational symmetry The inside contains through holes; the inner ring gasket 15 is bonded to the inner ring of the bearing 2 and fixed to the base 1 by screws; the outer ring of the bearing 2 is bonded to the outer ring gasket 16, and the outer ring gasket 16 passes through The screw and the housing 17 are fixed; the two anti-symmetrically arranged driving mechanisms include the first rhombic ring 3 and the second rhombic ring 10 and the first compression rings respectively installed in the first rhombic ring 3 and the second rhomb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com