U-shaped stepping piezoelectric actuator and method based on diamond ring wedge integrated clamp

A piezoelectric actuator, diamond ring technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of increasing the axial size of the actuator, inability to Work for a long time, the actuator cannot be completed, etc., to achieve the effect of improving space utilization, simple structure, and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

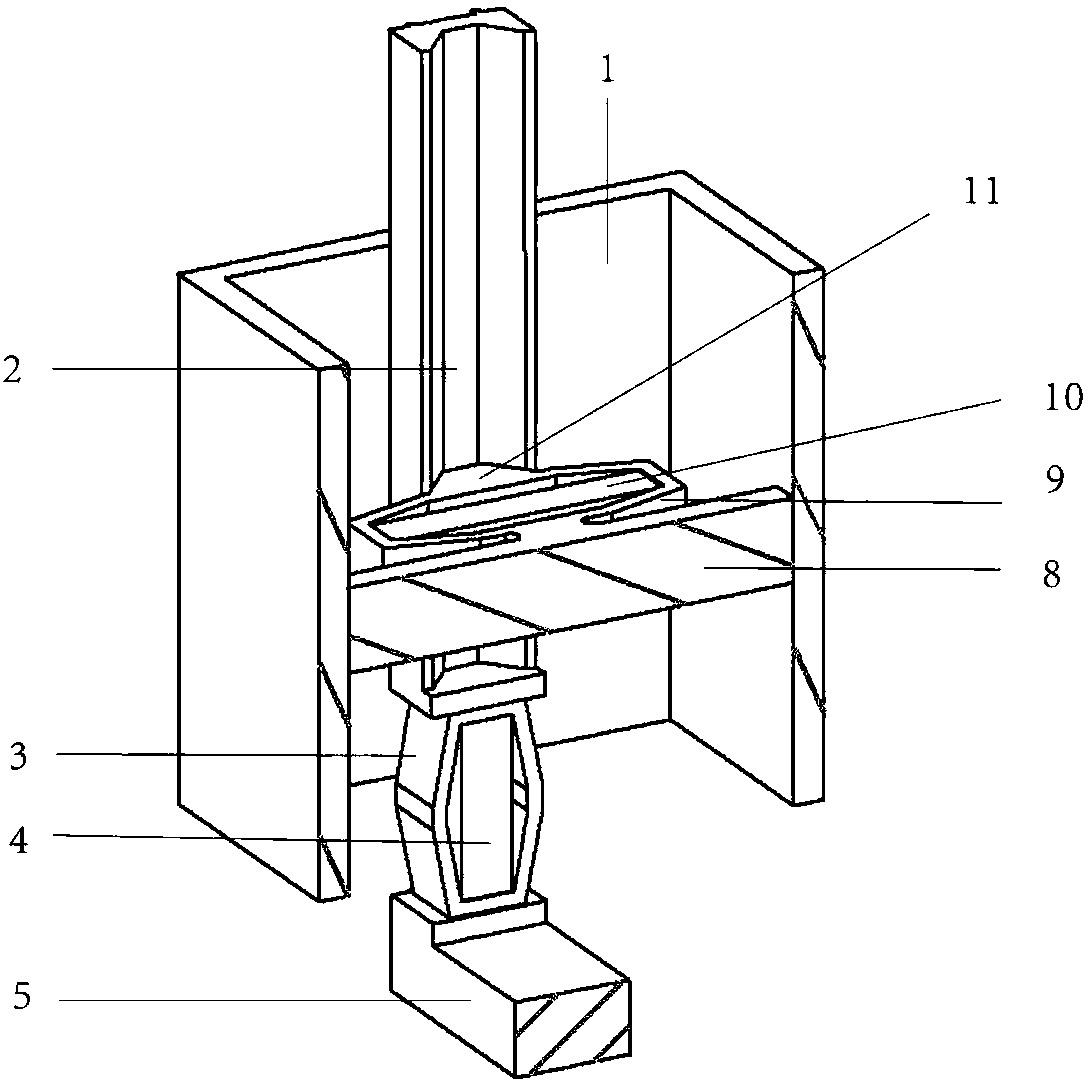

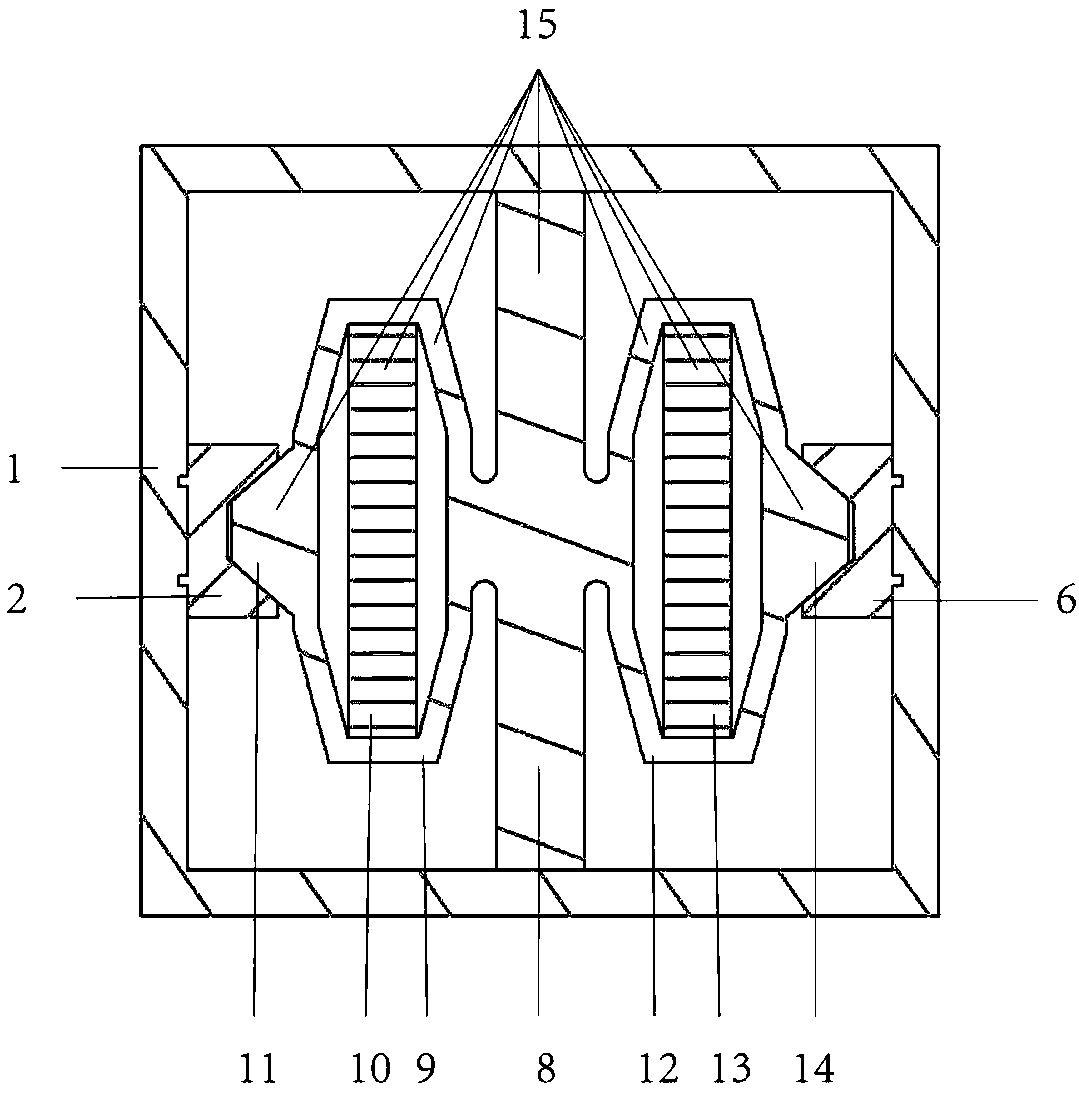

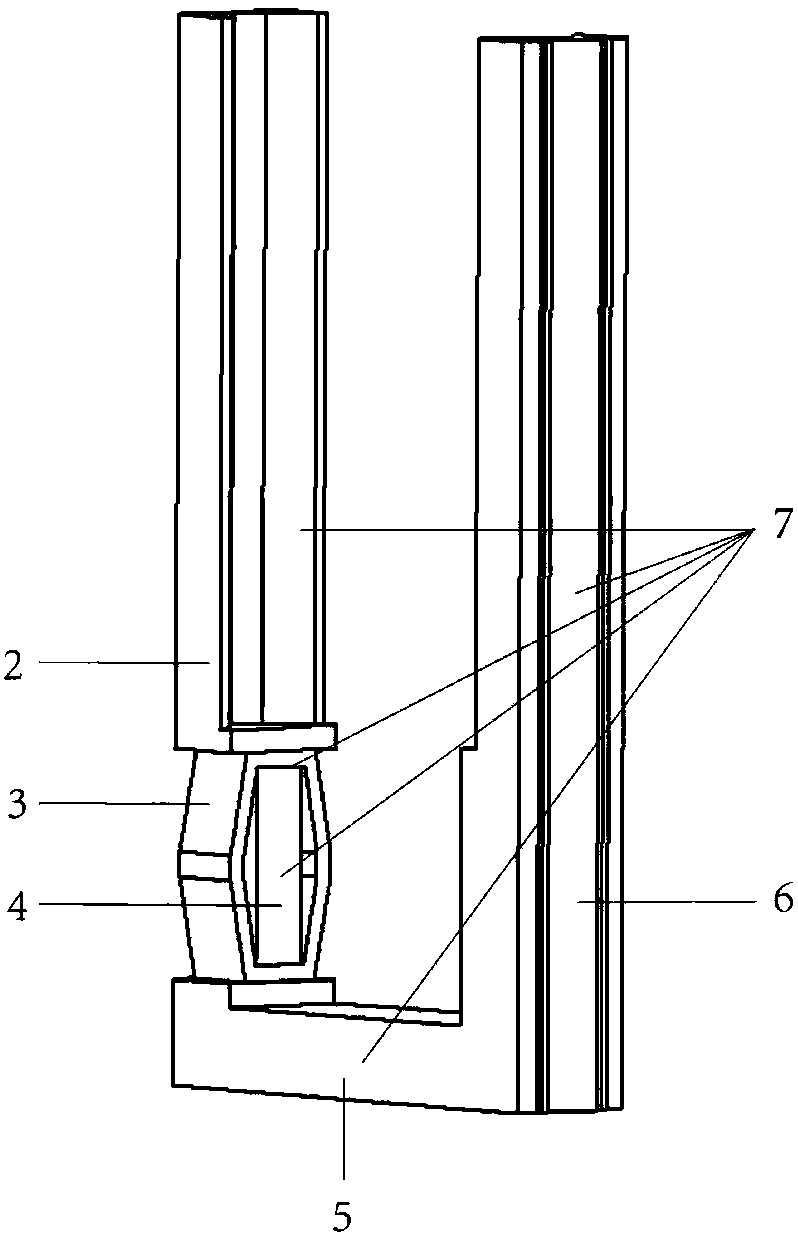

[0024] Such as figure 1 , figure 2 with image 3 As shown, the present invention is based on a U-shaped stepping piezoelectric actuator clamped by a diamond-shaped ring wedge integrated, including a housing 1, a U-shaped rod 7 that cooperates with the housing 1 through a guide rail, and is fixed on the housing through a rectangular cross-section beam 8. 1. A diamond-shaped ring wedge integrated clamping mechanism 15 in the middle of the interior; the left side long bar 2 of the U-shaped bar 7 is embedded with a long axis along the length direction of the left side long bar 2 at the bottom of the output bottom plane 5. Rhombus driving mechanism 3, the rhombus driving mechanism 3 is interference-fitted with driving piezoelectric stack 4 along the long axis direction; the longitudinal symmetry axis of the rhomboid ring wedge integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com