Application of a rework jig for forming ultra-thick circuit boards

A circuit board and fixture technology, applied in the direction of circuit board tool positioning, printed circuit, printed circuit manufacturing, etc., can solve the problems of inability to apply, shift, unstable adsorption, etc., to improve rework yield, simple operation, and reduce rework effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

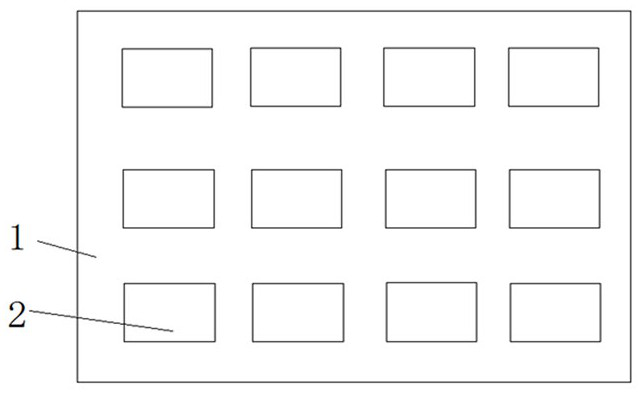

Image

Examples

Embodiment 1

[0024] The production and application of a rework jig for forming an ultra-thick circuit board, the production steps are as follows:

[0025] Step S1, laminating sheet material: design the thickness of the ultra-thick circuit board rework jig according to the thickness of the ultra-thick circuit board, the thickness of the ultra-thick circuit board rework jig is less than 0.2mm of the thickness of the ultra-thick circuit board, and laminate the board according to the designed thickness material, that is, the reworked fixture substrate;

[0026] Step S2, drawing and printing the size of the fixture: according to the size of the ultra-thick circuit board, the size of each side of the ultra-thick circuit board rework fixture is determined to be 0.1mm larger than the size of each side of the ultra-thick circuit board, and the shape of the ultra-thick circuit board rework fixture is the same as The shape of the ultra-thick circuit board is consistent, and the jig design drawing is ...

Embodiment 2

[0032] The production and application of a rework jig for forming an ultra-thick circuit board, the production steps are as follows:

[0033] Step S1, laminating sheet material: design the thickness of the ultra-thick circuit board rework jig according to the thickness of the ultra-thick circuit board, the thickness of the ultra-thick circuit board rework jig is less than 0.5mm of the thickness of the ultra-thick circuit board, and laminate the board according to the designed thickness material, that is, the reworked fixture substrate;

[0034] Step S2, jig size drawing: according to the size of the ultra-thick circuit board, determine the size of each side of the ultra-thick circuit board rework fixture to be 0.2mm larger than the size of each side of the ultra-thick circuit board, and the shape of the ultra-thick circuit board rework jig is the same as The shape of the ultra-thick circuit board is consistent, and the jig design drawing is drawn and printed on the rework jig ...

Embodiment 3

[0040] The production and application of a rework jig for forming an ultra-thick circuit board, the production steps are as follows:

[0041] Step S1, laminating sheet material: design the thickness of the ultra-thick circuit board rework jig according to the thickness of the ultra-thick circuit board, the thickness of the ultra-thick circuit board rework jig is less than 0.8mm of the thickness of the ultra-thick circuit board, and laminate the board according to the designed thickness material, that is, the reworked fixture substrate;

[0042] Step S2, drawing and printing the size of the fixture: according to the size of the ultra-thick circuit board, the size of each side of the ultra-thick circuit board rework fixture is determined to be 0.1mm larger than the size of each side of the ultra-thick circuit board, and the shape of the ultra-thick circuit board rework fixture is the same as The shape of the ultra-thick circuit board is consistent, and the jig design drawing is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com