Double-head press stud machine

A buckle machine and casing technology, which is applied in the field of clothing processing, can solve the problems of low work efficiency of the big white buckle machine, and achieve the effect of saving time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

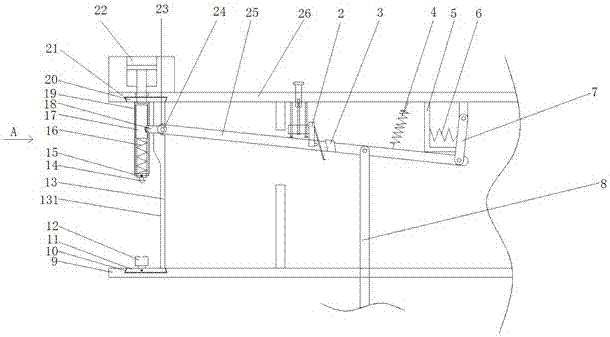

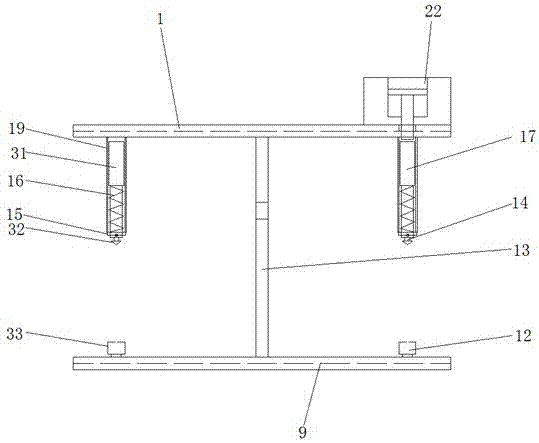

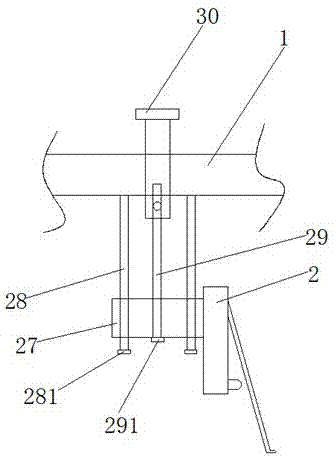

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] A specific embodiment of a large white buckle machine of the present invention, as Figure 1-Figure 3 As shown, the double-headed large white buckle machine includes a casing 1 and a connecting rod 25 that is arranged inside the casing 1 and can move up and down. The rear end of the connecting rod 25 is hinged with the casing 1, and the connecting rod 25 is hinged with a pedal rod 8. The front end of the casing 1 is provided with left and right punches 31 and right punches 17 that can slide left and right to be hinged with the front end of the connecting rod 25. The lower end of the left punch 31 is detachably connected with a left upper die 32, and the lower end of the right punch 17 can The upper right die 14 is disassembled and connected, and the workbench 9 on the casing 1 is provided with a lower left die 33 and a lower right die 33 correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com