Fire-fighting robot capable of achieving automatic patrolling

A fire-fighting robot and fire-monitor technology, applied in the field of automation, can solve the problems of time delay, time-consuming and labor-intensive fire fighting, and inability to use sprinkler fire-fighting, etc., and achieve the effect of simple equipment installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

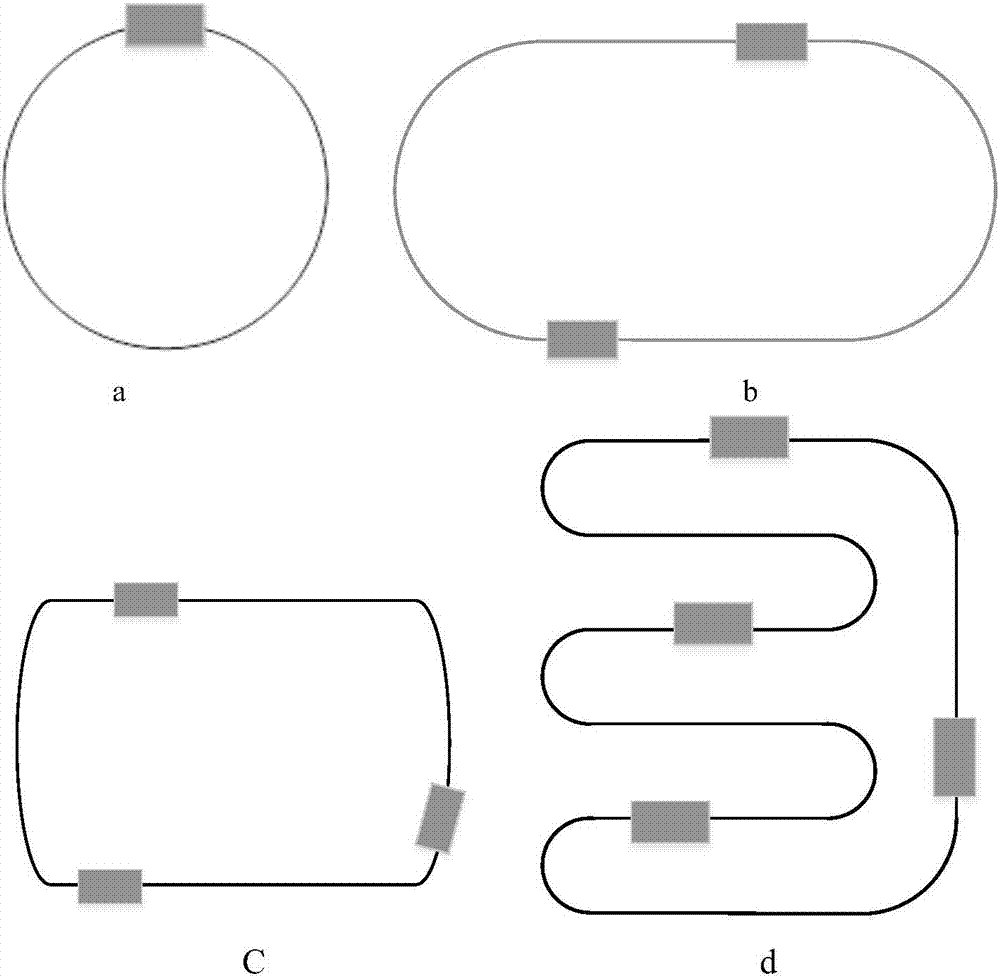

[0025] The present invention proposes an automation equipment. By arranging a closed running track or slideway on the ceiling or side of the wall inside the building, according to the fire protection range and the requirements of the building size, the types of closed running tracks are different, such as figure 1 As shown, including circle, rounded rectangle, ellipse, S-shaped combined shape, etc., according to the size of the fire fighting area, multiple automatic patrol fire fighting robots can be set up in the closed track, arranged at equal intervals, and coordinated on the cruise line Cruise to realize the circular patrol of fire-fighting robots; after discovering a fire, other automatic fire-fighting robots in the closed patrol line will gather towards the fire point and automatically extinguish the fire scene until it is detected that the fire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com