Rotating base of industrial robot

A technology of industrial robots and rotating bases, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of inability to cool down and clean up the gaps and debris, and achieve the effect of ensuring clean and hygienic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

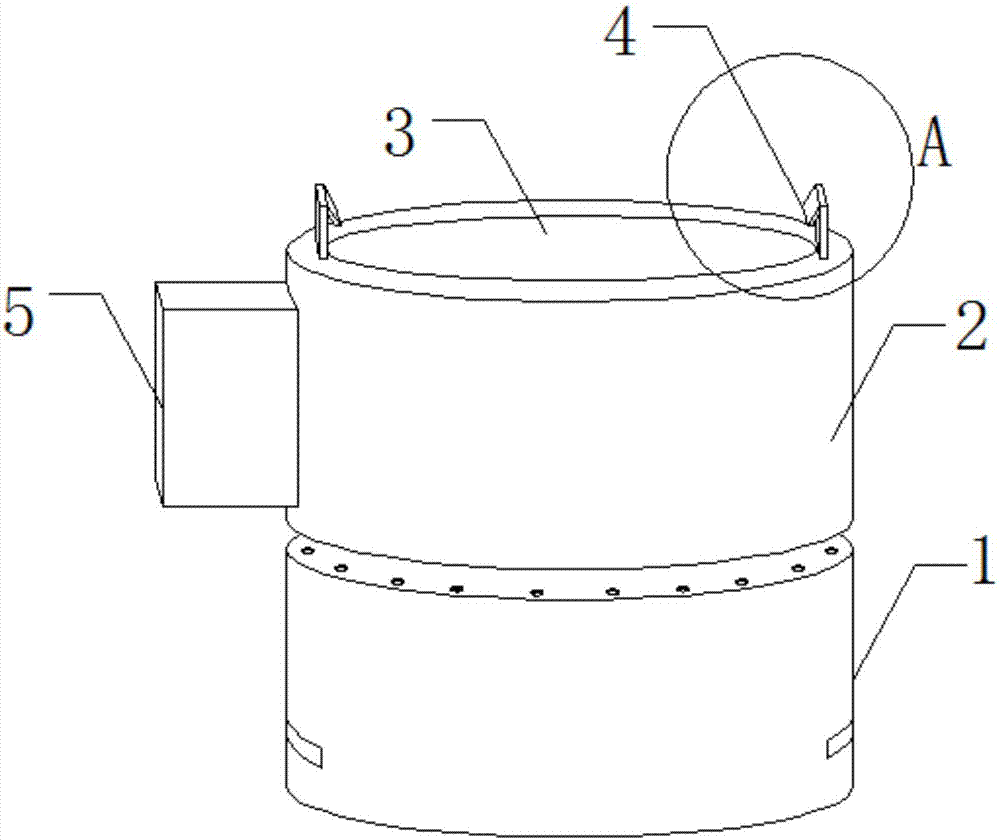

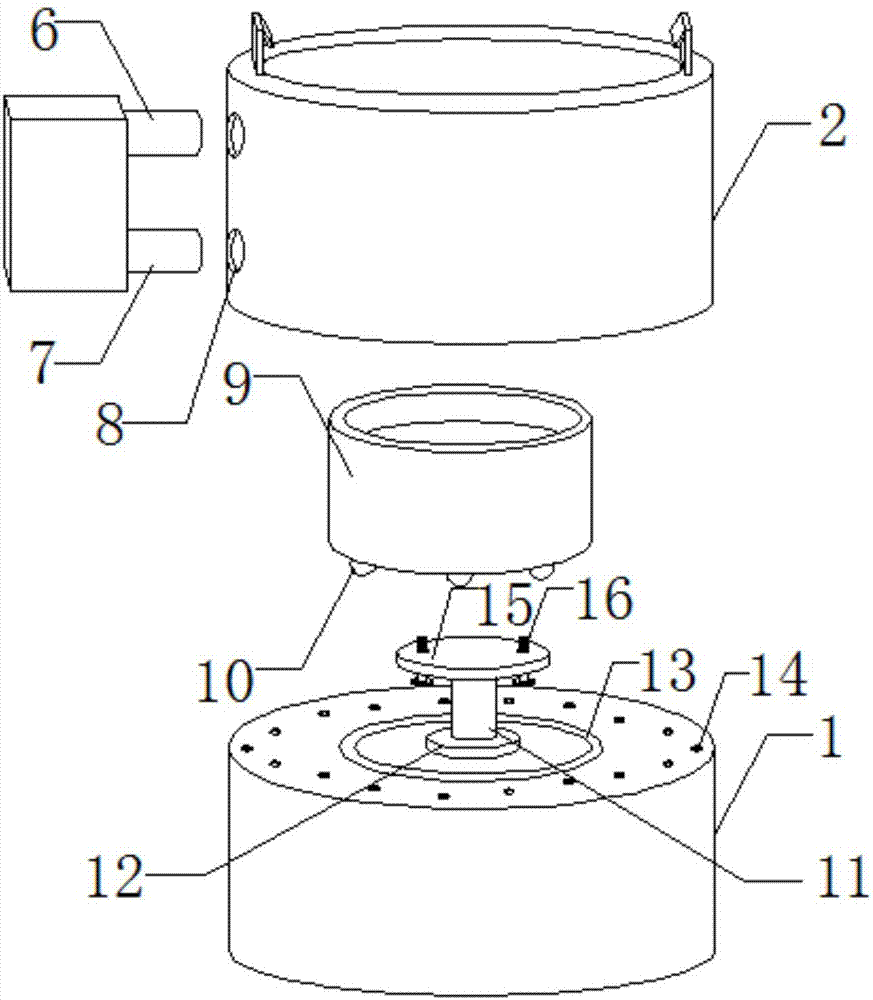

[0023] see Figure 1-4 As shown, a rotating base of an industrial robot includes a fixed base 1 and a support base 2. A slot 3 is provided inside the support base 2 to engage the bottom of the industrial robot. Both sides of the top of the support base 2 are welded with buckles. 4, and the buckle 4 is engaged with the side wall of the robot to ensure the stability of the robot. The side wall of the support seat 3 is provided with a water tank 5, and the water tank 5 is filled with cooling liquid. The bottom is provided with a water inlet pipe 7, and one end of the water inlet pipe 6 and the water inlet pipe 7 is engaged in the clamping hole 8, and the bottom of the support seat 2 is welded with a support frame 9 to support and fix the support seat 2, and the bottom of the support frame 9 is engaged with a number of balls 10 , and the bottom of the ball 10 is engaged in the chute 13, and can slide in the chute 13, the middle part of the fixed seat 1 is engaged with the rotating...

Embodiment 2

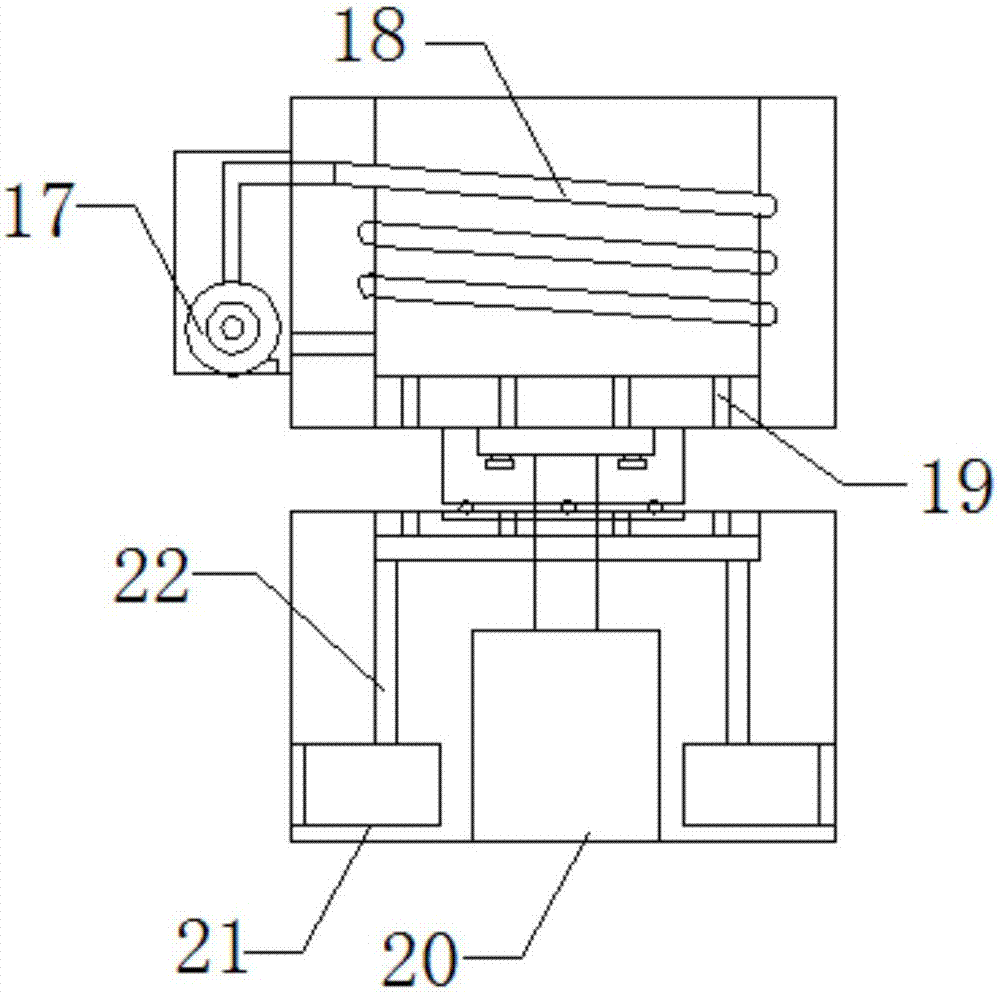

[0025] In addition, please continue to Figure 2-4 As shown, the difference between it and Embodiment 1 is that the support seat 2 is arranged directly above the fixed seat 1, and the support seat 2 has a cylindrical structure, so that the base can be fixed more stably and firmly, ensuring that the base can rotate and work, and the fixed The bottom plate 15 is fastened to the bottom of the support base 2 through bolts 16, and the fixed base plate 15 is arranged in the middle of the support frame 9, so that the fixed plate 15 can be firmly engaged and fixed on the bottom of the support base 2 to ensure the stability of the support base 2 , one end of several balls 10 is engaged in the bottom of the fixed frame 9, the other end is engaged in the chute 13, and the balls 10 and the chute 13 are rotationally connected, so that the balls 10 can slide in the chute 13, which is convenient for the support seat 2 Rotate to adjust the position, the water pump 17, the motor 20, and the ex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap