Lifting appliance for specially lifting cylindrical materials and crane thereof

A cylindrical, spreader technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of low degree of automation, waste of labor costs, insufficient suction, etc., and achieve the effect of reliable lifting operation and wide range of material sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

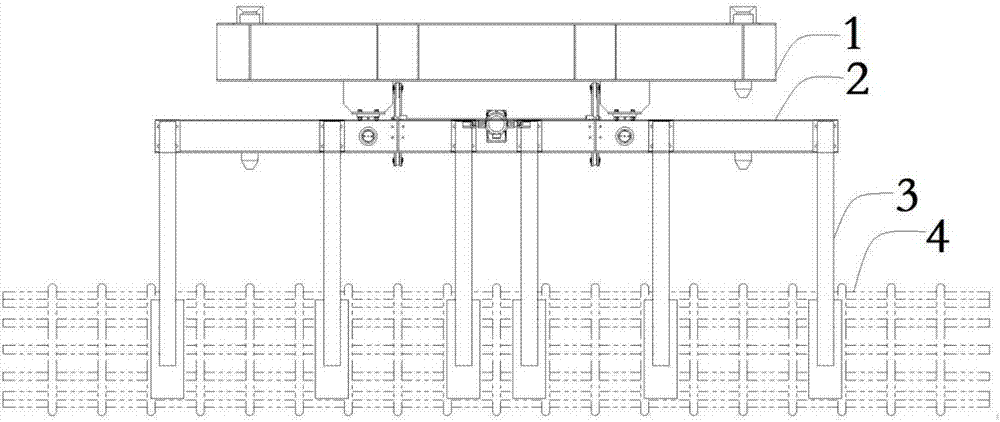

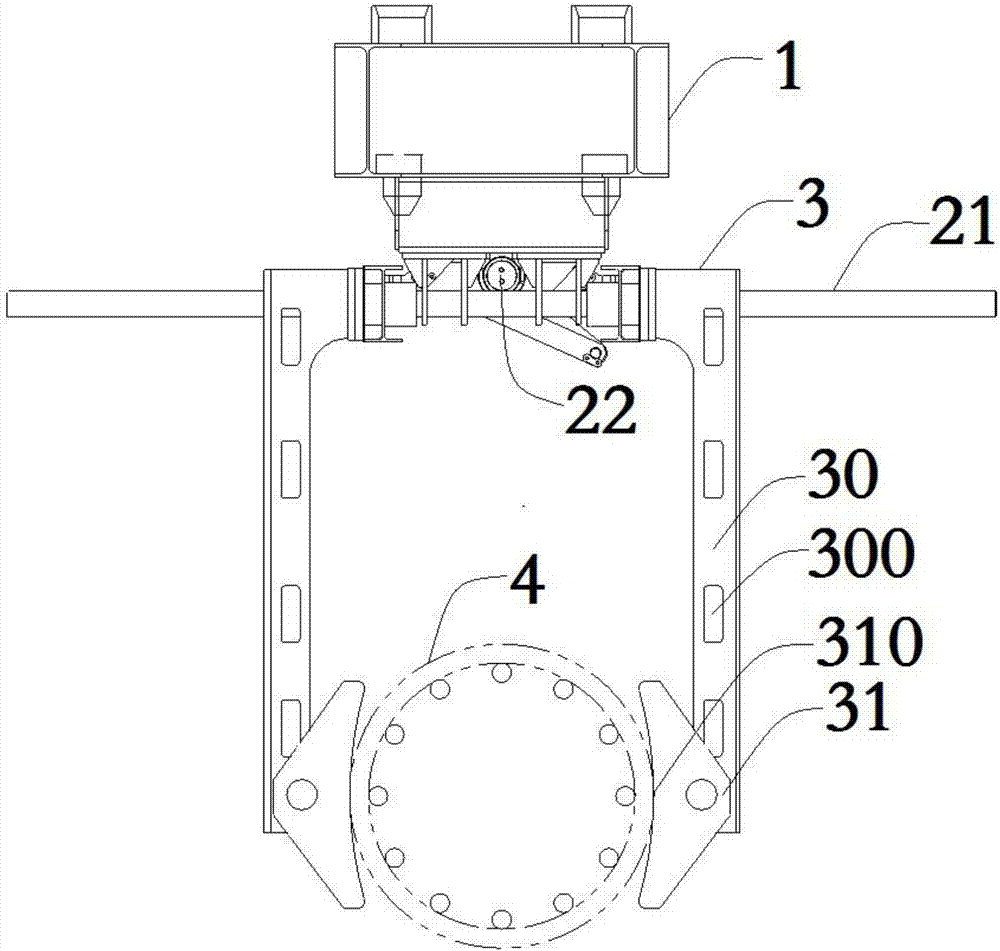

[0028] Such as Figure 1~5 As shown, in this embodiment, a hoisting device dedicated to hoisting cylindrical materials 4 is provided, including a hoisting beam 1, a driving device 2 and a number of hoisting parts 3, the driving device 2 is arranged on the hoisting beam 1, and the hoisting device The component 3 is arranged on the drive device 2 .

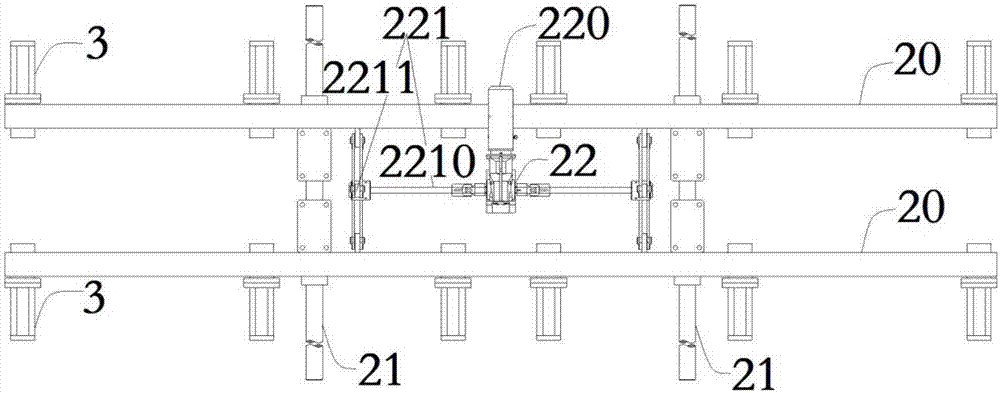

[0029] The driving device 2 includes two parallel beams 20, two beam support parts 21 perpendicular to the beams 20, and a driving mechanism 22 for driving the beams to move. The two beams 20 are arranged on both sides of the driving mechanism 22. The driving device 2 The crossbeam support part 21 is fixedly arranged on the spreader beam 1, the crossbeam support part 21 passes through the crossbeam 20, and the driving mechanism 22 drives two crossbeams 20 to move on the crossbeam support part 21 along the vertical direction; the crossbeam 20 and the crossbeam support part 21 form The "well" shape setting not only ensures the stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com